التطبيقات المختلفة لـ كشك التوزيع، وكشك الوزن، وكشك أخذ العينات

تقدم معدات غرف الأبحاث YOUTH من شركة YOUTH مجموعة متنوعة من الحلول المتخصصة لتلبية احتياجات الصناعة المختلفة. في حين أن أكشاك التوزيع وأكشاك الوزن وأكشاك أخذ العينات تخدم أغراضًا مختلفة، إلا أنها تشترك في سمات مشتركة مع تلبية المتطلبات الفريدة.

السمات المشتركة:

- الحماية من التلوث:

توفر جميع المقصورات الثلاث بيئة محكومة تحمي من التلوث الخارجي، مما يضمن إجراء عمليات دقيقة ومضبوطة. - سلامة المشغل:

يوفر كل كشك مساحة عمل آمنة، مما يحمي المشغلين من المواد الخطرة ويعزز بيئة عمل آمنة. - المواءمة التنظيمية:

ويُعد الالتزام بمعايير الصناعة، مثل ISO 14644 وإرشادات إدارة الغذاء والدواء الأمريكية، سمة مشتركة تعكس التزام شركة YOUTH بالجودة والامتثال. - التخصيص:

يمكن تصميم جميع المقصورات حسب احتياجات الصناعة المحددة، والتكيف بسلاسة مع المتطلبات المتنوعة. - كفاءة سير العمل:

تعمل العمليات المبسطة وتقليل الهدر على رفع الكفاءة التشغيلية عبر أكشاك التوزيع والوزن وأخذ العينات.

سمات فريدة من نوعها:

- كشك التوزيع:

- صُممت لإدارة المواد الحساسة في مجالات الأدوية والتكنولوجيا الحيوية والإلكترونيات.

- يحافظ على سلامة المنتجات ويقلل بشكل كبير من مخاطر التلوث طوال عملية التوزيع.

- إعطاء الأولوية للقضاء على التلوث، والتعامل الدقيق مع المواد، وحماية الأفراد. - كشك الوزن:

- يضمن تصميم الضغط السلبي الفريد احتواء المساحيق ومنع انتشارها خارج المقصورة وحماية جو غرفة التنظيف الداخلية.

- كشك وزن المسحوق مخصص لتقديم قياسات دقيقة وفعالة ضرورية للصناعات التي تتطلب دقة عالية.

- يحقق تحديدات وزن متسقة ودقيقة من خلال التخفيف من اضطرابات تدفق الهواء الخارجي.

- يسلط الضوء على المكاسب الاقتصادية والزمنية من خلال تقليل الحاجة إلى التصحيحات والهدر، وبالتالي تعزيز الإنتاجية التشغيلية. - كشك أخذ العينات:

- مصممة خصيصاً للقطاعات التي تعتمد على أخذ عينات دقيقة لضمان نتائج موثوقة.

- يحافظ على منطقة ضغط إيجابي لمنع الملوثات من الدخول والتأثير على صحة العينات.

- مزودة بإضاءة آلية لضمان الرؤية الواضحة أثناء أنشطة جمع العينات.

باختصار، YOUTH's YOUTH معدات غرف الأبحاث تقدم أكشاك التوزيع والوزن وأخذ العينات التي تشترك في السمات الأساسية للحماية من التلوث، وسلامة المشغل، والمواءمة التنظيمية، والتخصيص، وكفاءة سير العمل. تخدم هذه الأكشاك أغراضًا متميزة، وتلبي الاحتياجات المحددة للصناعات مع الحفاظ على التزام YOUTH بالتميز والابتكار والدقة التشغيلية.

ميزات منتج YOUTH

منفاخ

- منفاخ روزنبرغ في صندوق الهواء المستقل.

- منفاخ طرد مركزي فعال وخالٍ من التزييت.

- تدابير أمنية مدمجة لحماية النظام والمستخدم.

جهاز مزود بمضخة هوائي هوائي هوائي هوائي

- HEPA الموجود في قسم الضغط الإيجابي بعد المنفاخ.

- سهولة التركيب والإزالة الفردية للصيانة.

- مصممة لاختبار التسرب المريح.

ديفوسر

- إطار واقي SS304/SS316L مقاس 20 مم

- التكامل السلس مع سطح مخرج المقصورة

- مصممة للصيانة المباشرة

- يحسن اتساق مخرج الهواء والإضاءة والتهوية

- خيار: قابل للتخصيص مع ألواح مثقوبة بالكامل من الفولاذ المقاوم للصدأ

- اختياري: تأتي مع إضاءة أنبوبية مسطحة مريحة لسهولة الصيانة المستقبلية

سوكيت

هذا المقبس من نوع Mennekes/Philips، وهو معياري للمرونة، ويستوعب 220 فولت و380 فولت، ويحقق مستوى إحكام الإغلاق IP55/IP65 لأداء إحكام فعال.

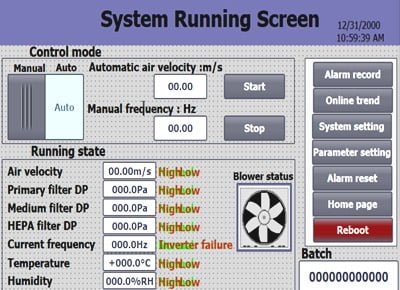

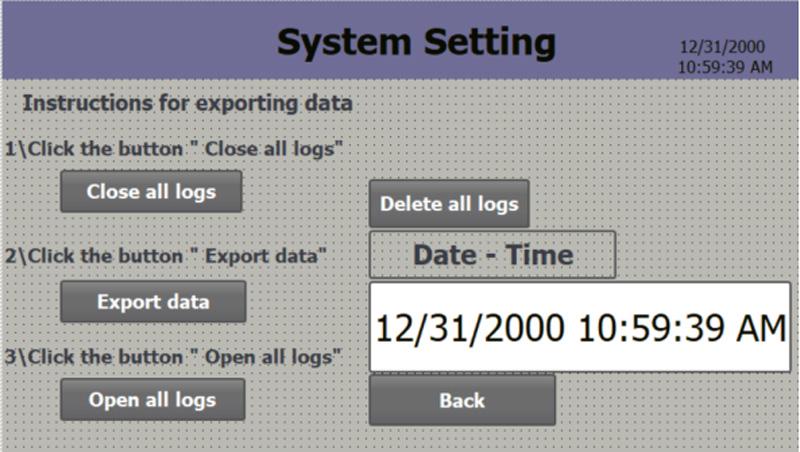

نظام التحكم plc

تعتمد وحدة التحكم المنطقي القابل للبرمجة القابلة للبرمجة SIEMENS PLC و HMI وحدة CPU224 القابلة للتوسيع (بما في ذلك نظام التخزين) تعتمد وحدة SIEMENS (وحدة EM231، EM235) جميع المكونات الكهربائية تستخدم SCHNEIDER.

الإضاءة

مزوّدة بمصابيح T5 ذات حامل T5 مع أغطية لإضاءة فعّالة بإضاءة لا تقل عن 350 لوكس. باستخدام ناشر سقف PET لضمان إضاءة متساوية ومتسقة.

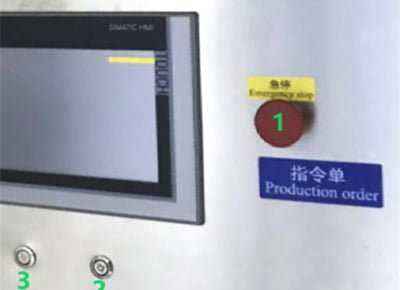

الأزرار ونظام الإنذار

زر إيقاف الطوارئ

مفتاح الطاقة

الإنذارات المسموعة

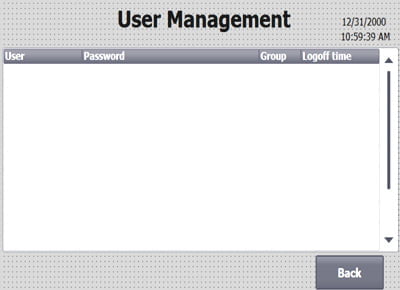

3-4 هيئة الوصول 3-4 هيئة الوصول

مشغل من المستوى 1

مهندس المستوى 2

مسؤول ليفل 3 المسؤول

نظام المستوى 4

اختبار المراجعة والتدقيق

نحن نستخدم مفاتيح التشفير من Siemens التي تتوافق مع متطلبات CFR21، مما يضمن أن عملية التوزيع قابلة للتتبع والتحقق ومتوافقة مع جميع اللوائح ذات الصلة.

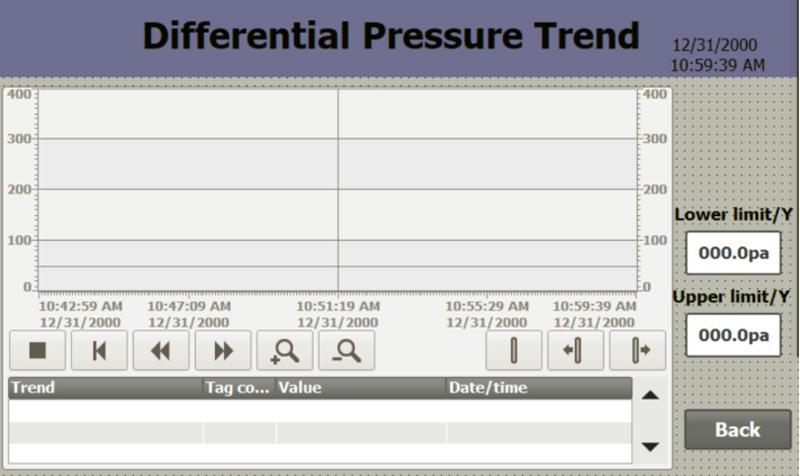

مراقبة اتجاه الضغط التفاضلي

مراقبة اتجاه الضغط التفاضلي لضمان سلامة وفعالية المنتجات الصيدلانية مع الامتثال للمتطلبات التنظيمية.

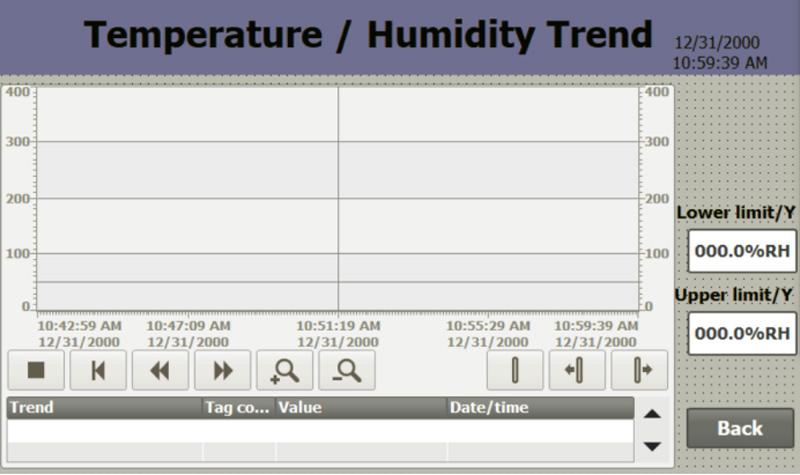

مراقبة اتجاه درجة الحرارة والرطوبة

مراقبة درجة الحرارة والرطوبة في أكشاك التوزيع أمر بالغ الأهمية. يساعد ذلك على ضمان تصنيع المنتجات الصيدلانية وتخزينها في الظروف المناسبة

كشك وزن YOUTH مقابل كشك وزن YOUTH. أخرى

هيكلية الشباب

تتميز منتجات الشباب بهيكل متكامل مع تصميم قوس دائري يمنع الانفصال ويزيل أي فجوات لحام. وينتج عن ذلك مظهر جذاب ورشيق بصرياً.

الهيكلية الأخرى

يتم ربط منتجات الشركات المصنعة الأخرى إما بزاوية قائمة وملتصقة ببعضها البعض، أو يتم ربطها بألواح ألومنيوم دائرية على شكل قوس قد تنفصل بمرور الوقت، مما يشكل مخاطر محتملة على التكوين.

انحناء الشباب

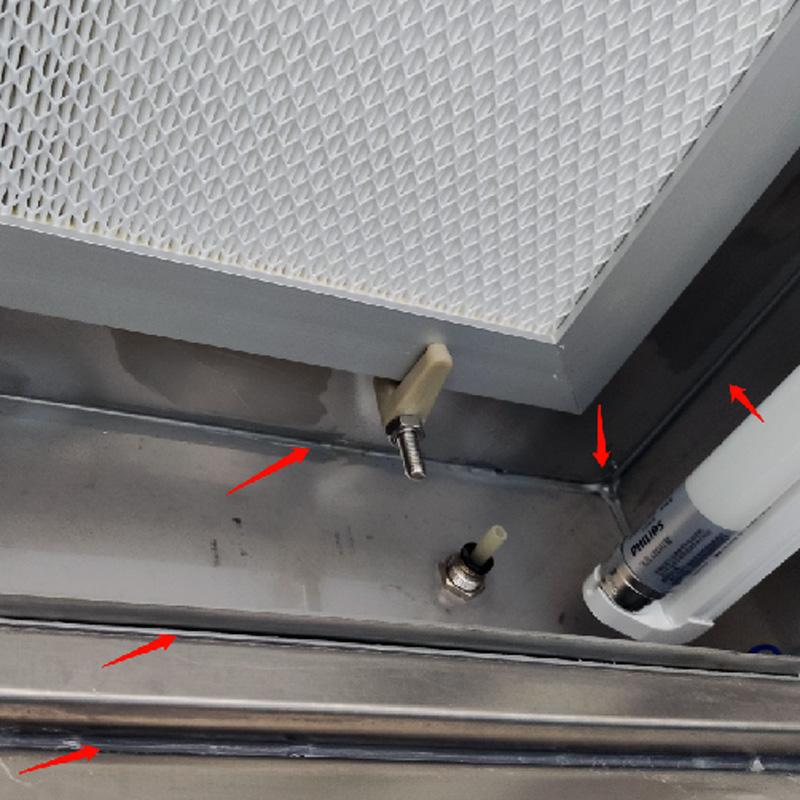

تخضع منتجات الشباب إلى ثني اللوح بالكامل واللحام الكامل لتقليل أي ثغرات في المعدات. تُعد حافة سكين منع التسرب في الفلتر عنصراً حاسماً يجب أن يضمن عدم حدوث أي تسرب.

ثني الآخرين

يستخدم مصنعون آخرون اللحام الموضعي والمواد اللاصقة لإغلاق مكوناتها الداخلية، معتمدين فقط على الغراء لإنشاء مانع تسرب. يشكل هذا النهج خطرًا كبيرًا للتسرب على مدى فترة طويلة.

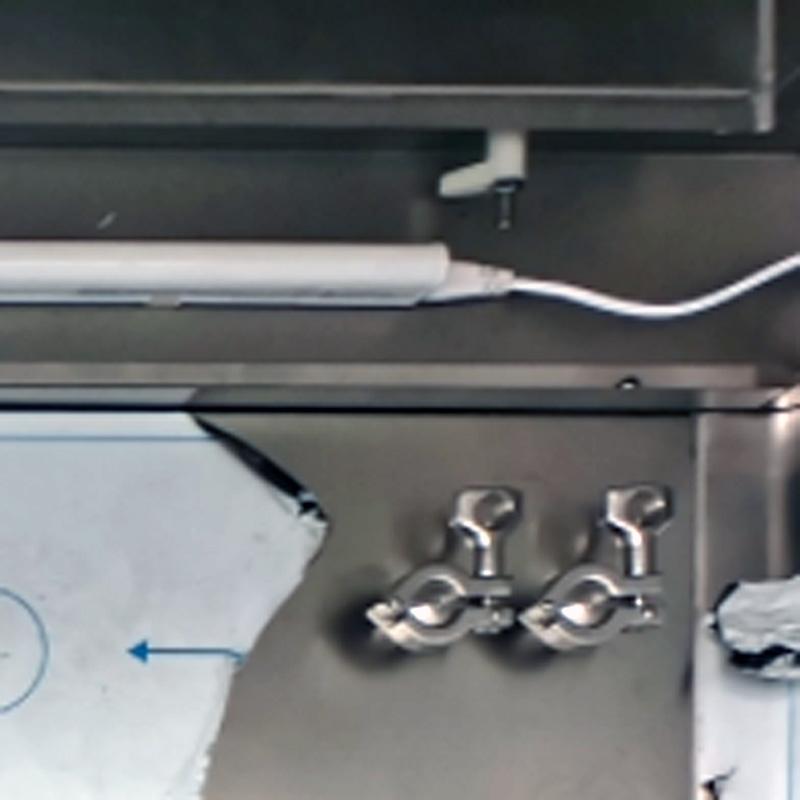

تصميم صندوق الشباب

يتميّز صندوق الشباب غير المرئي بصندوق غير مرئي يتميز بتصميم داخلي مرتب ومعتنى به جيداً. تم تجهيز المروحة بدفاعات من الألومنيوم من روزنبورغ، وهي مزودة بدفاعات من الألومنيوم من روزنبورغ، وهي محاطة بصندوق من الفولاذ المقاوم للصدأ، مما يمنع تراكم الغبار بشكل فعال. وعلى النقيض من ذلك، فإن حجرات الوزن في المنتجات الأخرى عرضة لتراكم الغبار مع مرور الوقت، ولكن هيكلنا الداخلي مصمم لسهولة التنظيف، مما يضمن صيانة خالية من المتاعب.

تصميم الصناديق الأخرى

وتفتقر مراوح الشركات المصنعة الأخرى إلى تعريف العلامة التجارية، وهي مجلفنة فقط، ومعرضة للصدأ، وتفتقر إلى غلاف، مع تقنية معالجة خشنة. كما أن الأسلاك غير منظمة وتشكل خطرًا كبيرًا على السلامة بسبب نهايات الأسلاك المكشوفة، مما يؤدي إلى تسرب كهربائي. على النقيض من ذلك، تتميز منتجات Youth بتصميم مروحة فائق وأسلاك منظمة، مما يضمن تشغيلًا آمنًا وموثوقًا.

صيانة الشباب

يزيل تصميم غشاء معادلة التدفق الخاص بالشباب أي كتل ضغط مكشوفة، مما يجعل من السهل صيانته على أساس يومي.

صيانة الآخرين

استخدام الشركات المصنعة الأخرى للقوالب المكشوفة يجعل التنظيف اليومي مهمة غير مريحة.

تصميم الشباب المغناطيسي

يتميّز فلتر الاستبدال الخاص بالشباب بهيكل شفط مغناطيسي مبتكر يزيل كتل الضغط والبراغي على السطح، مما يضمن عملية استبدال خالية من المتاعب. توفر طريقة التثقيب إما فتحة خصر مستديرة أو مستطيلة الشكل، مما يسهل سحب اللوحة المغناطيسية بالأصابع.

التصميم المغناطيسي للآخرين

يتضاءل استخدام الشركات المصنعة الأخرى للمقابض الخارجية أو الأبازيم مقارنةً بتصميم الشفط المغناطيسي المبتكر من Youth، والذي يوفر راحة فائقة.

ميزات الشركة المصنعة لكشك التدفق الهابط YOUTH

عندما يتعلق الأمر بضمان بيئة نظيفة وخاضعة للرقابة للعمليات الصيدلانية، يصبح دور الشركة المصنعة لمقصورة التدفق السفلي الموثوق بها أمرًا لا غنى عنه. تتخصص شركة YOUTH، وهي اسم رائد في هذا المجال، في إنشاء مقصورات التدفق السفلي المتطورة التي غالبًا ما تُستخدم في غرف التوزيع. توفر هذه المقصورات بيئة دقيقة حيث يمكن التعامل مع المواد بأمان دون التعرض لخطر التلوث. تضمن غرفة التوزيع المجهزة بأكشاك من شركة YOUTH، الشركة المصنعة لأكشاك التدفق الهابط ذات السمعة الطيبة، حماية كل من المشغلين والمواد من الملوثات المحمولة جواً. تضمن الشراكة مع YOUTH التزام الشركات بأعلى معايير جودة المنتج وسلامته.

المحتويات ذات الصلة:

- ما الفرق بين كشك الوزن وكشك التوزيع؟

- كل ما يجب أن تعرفه عن أكشاك الوزن

- الدور الأساسي لأكشاك قياس الوزن YOUTH

- الدليل النهائي لأكشاك التوزيع وأخذ العينات والوزن: ضمان الدقة والسلامة باستخدام YOUTH

- أكشاك غرف الأبحاث: الدليل الشامل لأكشاك التوزيع وأخذ العينات والوزن YOUTH

- أنظمة إدخال الأكياس في الأكياس/إخراجها (BIBO): دليل التشغيل والصيانة

- أكشاك الغرف النظيفة المتخصصة من YOUTH: ضمان الدقة والسلامة

- أفضل أكشاك قياس الوزن لتطبيقات غرف الأبحاث

- 5 تصاميم مبتكرة لكابينة الوزن لمختبرك