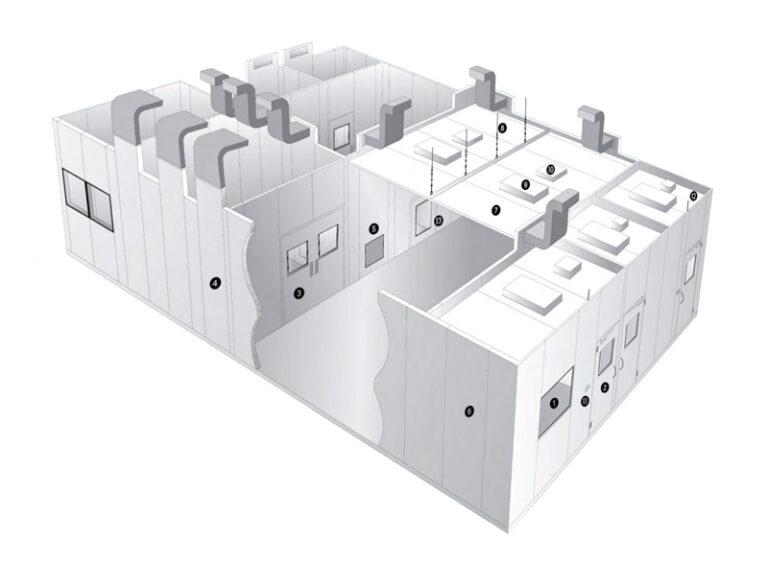

- Window

- Single swing door

- Double swing door

- Return air riser (inbuilt)

- Grille

- Wall panel

- Ceiling panel

- Hanger

- Room light

- Supply air inlet

- Light switch

- Concealed electrical conduit

- Cart-in Pass box

Cleanroom System

A cleanroom system refers to a controlled environment that is designed to minimize the introduction, generation, and retention of pollutants such as dust, microorganisms, and chemicals, that can have an adverse impact on products and processes in various industries, including semiconductor, pharmaceutical, and biotechnology. Cleanroom systems typically consist of various components such as wall panels, ceilings, flooring, and windows and doors, which are designed to meet specific cleanliness and contamination control requirements. These systems play a crucial role in ensuring that the controlled environment remains free from contaminants, which can compromise product quality and production yields.

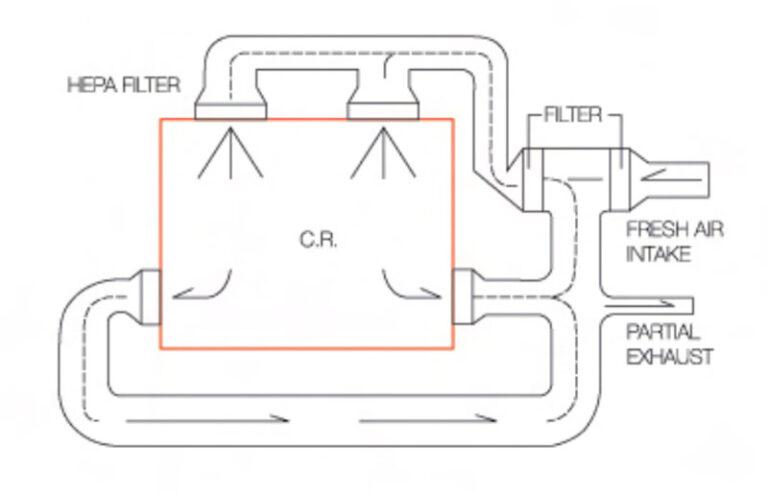

Conventional System

The cleanroom utilizes a ceiling-mounted filtration system to introduce filtered air into the room, effectively diluting any contaminants present. Return air is extracted from a bottom corner to ensure a continuous flow of clean air. The cleanroom is capable of achieving a cleanliness level between class 10,000 and 100,000. However, installing HEPA filters at the inlets and increasing ventilation frequency to 30 times per hour can achieve a near-class 1,000 cleanliness level. It’s worth noting that the cleanliness level is higher near the inlets and decreases near the outlets, as expected.

Laminar Flow Cleanrooms

Laminar flow cleanrooms use HEPA (High-Efficiency Particulate Air) filters to provide a uniform flow of clean air in one direction. This type of cleanroom is commonly used in pharmaceutical manufacturing and biotechnology industries where maintaining a sterile environment is critical.

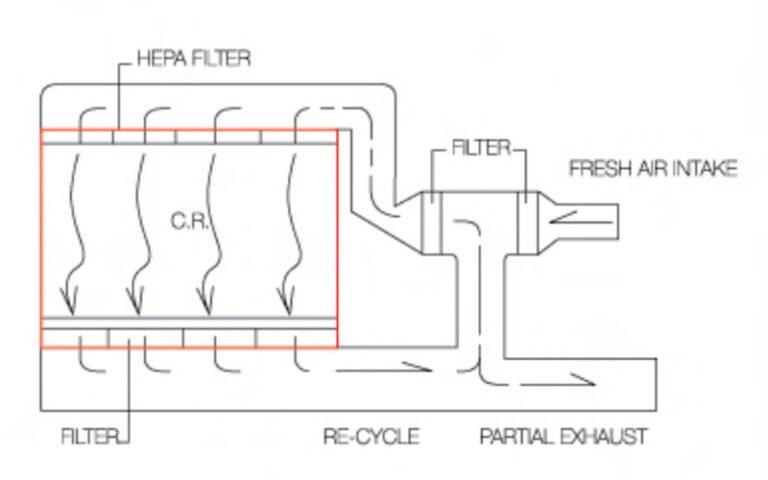

The Vertical Laminar System is a type of cleanroom system that is suitable for environments that require an ISO Class 100 or higher level of cleanliness. Air is blown downwards through HEPA filters in a laminar flow pattern, and then extracted from the room floor. To achieve the highest level of cleanliness, a ventilation frequency of 432 times per hour is required, at a speed of 0.3 m/sec and a ceiling height of 2.5 meters.

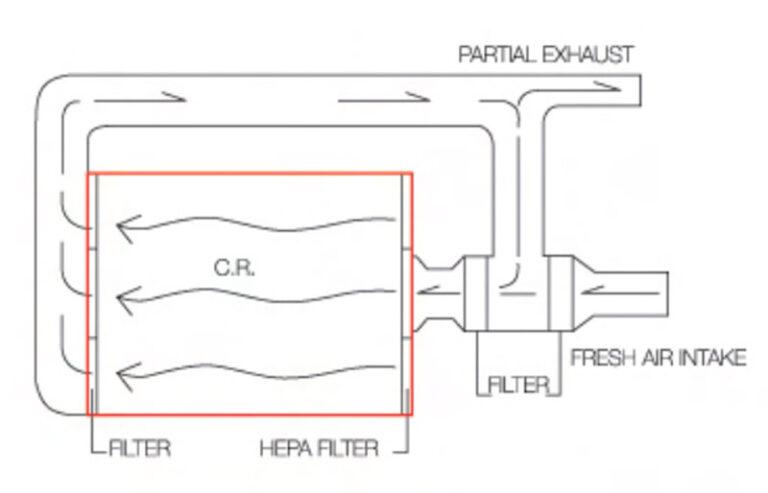

Horizontal Laminar System uses a HEPA filter to force air through and out of the opposite wall, creating a horizontal laminar flow pattern. It achieves a cleanliness level of class 100 to class 10,000 and is often used for clean benches.

How to choose the cleanroom system for your project?

The windows and doors in a cleanroom are designed to keep the environment as clean and sterile as possible. In a cleanroom, it is important to control the number of particles and contaminants that enter the environment. Windows and doors must be designed to prevent the entry of particles and contaminants and also to control the flow of air into the cleanroom.

When choosing windows and doors for a cleanroom, there are several important factors to consider, such as:

- Material: The material used to make the windows and doors should be chosen based on its ability to resist particles and contaminants, as well as its ability to withstand regular cleaning and sterilization processes. Common materials include aluminum, stainless steel, and PVC.

- Air Tightness: Windows and doors should be airtight to prevent the entry of particles and contaminants.

- Size and Configuration: The size and configuration of windows and doors should be chosen based on the size and shape of the cleanroom, as well as the flow of air into the cleanroom.

- Sealant: The sealant used to join the window or door frame to the wall should be chosen based on its ability to resist particles and contaminants, as well as its ability to withstand regular cleaning and sterilization processes.

When choosing windows and doors for a cleanroom, it is important to work with a reputable cleanroom equipment supplier to ensure that the right products are chosen for your specific needs and requirements.

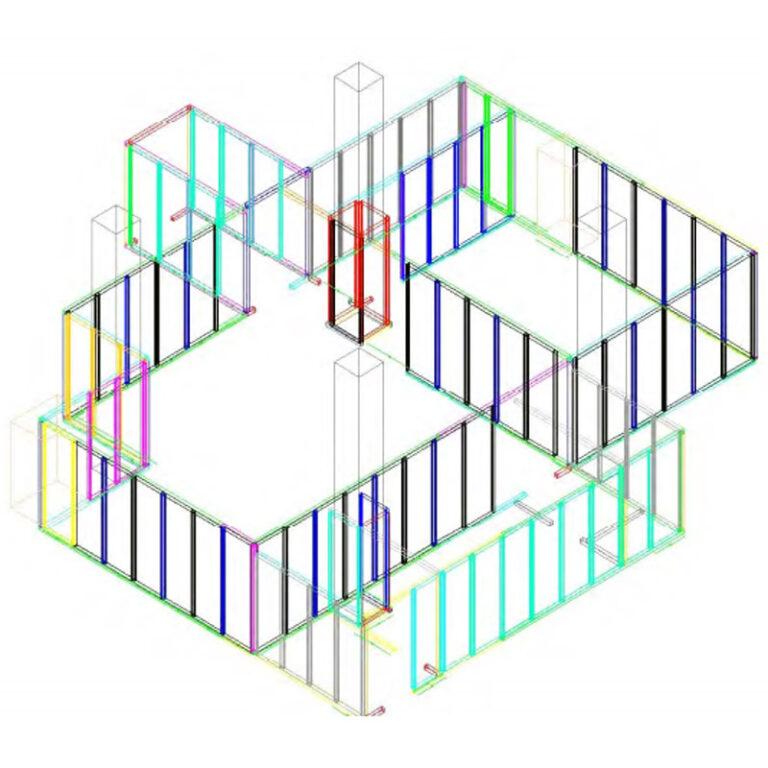

Cleanroom systems products

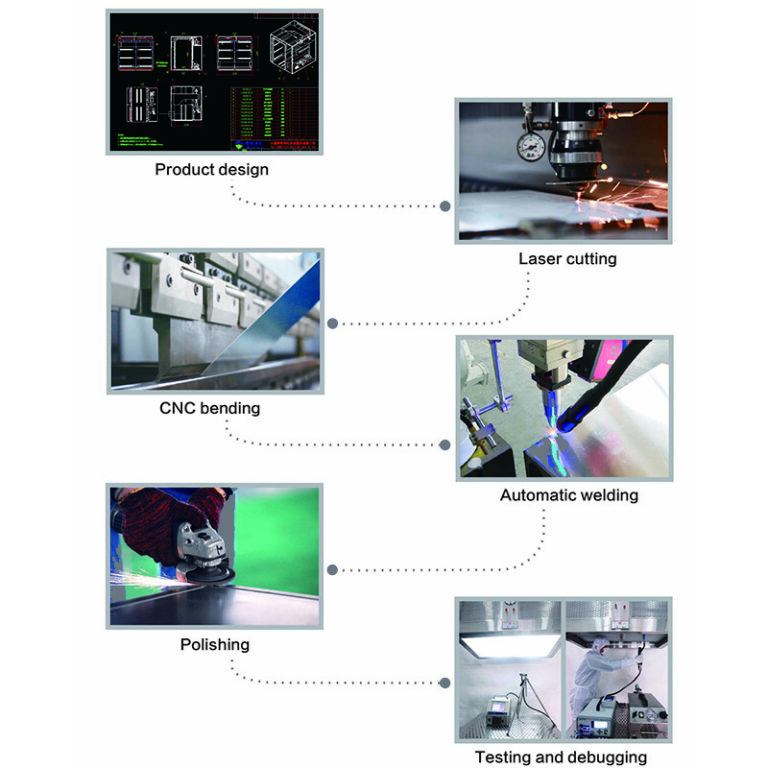

Youth-Tech's Feature

Our company has advanced production management capabilities with fully automated equipment for producing various types of cleanroom panels. The fillers include aluminum honeycomb, rock wool, PIR, PU, and other materials to meet the requirements of different production environments. We can customize different thicknesses, widths, and panel types according to your needs.

The rock wool and PIR material cleanroom panels have passed FM testing and meet the European and American standards for fire and flame resistance.

We use first-line brand steel coils from Korea or China as the base material, with a surface coating of anti-rust paint and colored paint. They have excellent corrosion resistance and are not susceptible to moisture, deformation, aging, etc., ensuring a long service life.