what is the BioSafe Stainless Steel Modular Cleanroom?

The BioSafe Stainless Steel Modular Cleanroom is an innovative and advanced cleanroom solution offered by YOUTH. It is specifically designed to provide a highly controlled and sterile environment for a wide range of industries. The cleanroom is constructed using high-quality stainless steel, which offers durability, corrosion resistance, and easy cleanability. It combines the benefits of modular flexibility and stainless steel construction to create a reliable and customizable cleanroom solution.

The BioSafe Stainless Steel Modular Cleanroom is designed to meet industry-specific cleanliness standards, such as ISO 14644 and Federal Standard 209E, ensuring compliance with regulatory requirements. It incorporates advanced filtration systems and air handling units to maintain the highest level of air quality by minimizing the presence of particles and microorganisms.

One of the key features of the BioSafe Stainless Steel Modular Cleanroom is its seamless integration with existing infrastructure. It can be customized to fit specific space constraints and workflow needs, allowing for efficient utilization of available space. The cleanroom’s layout is carefully planned to optimize workflow, minimize cross-contamination risks, and provide ergonomic workstations.

This cleanroom solution finds application in various industries, including pharmaceuticals, biotechnology, electronics, healthcare, hospitals, and research and development. It provides a controlled and sterile environment that ensures product integrity, patient safety, and reliable research outcomes.

In addition to its functionality, the BioSafe Stainless Steel Modular Cleanroom is designed to be cost-effective and offers a solid return on investment. By reducing product loss, improving efficiency, and meeting regulatory standards, businesses can benefit from increased productivity, higher product yields, and minimized waste.

YOUTH is dedicated to maintaining the cleanliness and quality of the cleanroom through recommended maintenance and cleaning procedures. Routine cleaning, proper disinfection protocols, and regular air filter replacements are essential for preserving the integrity of the cleanroom and ensuring optimal performance.

Overall, the BioSafe Stainless Steel Modular Cleanroom provided by YOUTH is a state-of-the-art solution that enables businesses to create a bio-safe and contamination-free environment. It combines cutting-edge technology, customization options, and adherence to quality standards to meet the unique cleanroom requirements of various industries.

Youth’s Features:

At YOUTH, we understand the importance of adhering to stringent specifications in high-level laboratories. That’s why we have developed an integrated all-negative pressure stainless steel sealed room that meets these requirements with precision. Our design ensures that every aspect of the enclosure structure, from the SUS304 stainless steel wallboard to the joints, fulfills the necessary pressure standards set for laboratory environments.

Benefits and Features of the BioSafe Stainless Steel Modular Cleanroom

The BioSafe Stainless Steel Modular Cleanroom offers a multitude of benefits to businesses seeking a sterile and controlled environment. Its key features include:

Superior Contamination Control: The stainless steel construction of the cleanroom minimizes the risk of contamination, providing a durable and clean surface that is easy to maintain.

Modular Flexibility: The modular design allows for easy customization, expansion, and reconfiguration to adapt to changing needs and evolving processes.

Enhanced Sterility: The BioSafe Stainless Steel Modular Cleanroom is equipped with advanced filtration systems and air handling units that ensure the highest level of air quality, minimizing the presence of particles and microorganisms.

Seamless Integration: The cleanroom seamlessly integrates with existing infrastructure, making it compatible with various equipment and systems, optimizing workflow efficiency.

Design and Construction of BioSafe Stainless Steel Modular Cleanrooms

When designing BioSafe Stainless Steel Modular Cleanrooms, several factors are taken into consideration. These include:

Cleanroom Classifications: The cleanroom is designed according to industry-specific cleanliness standards, such as ISO 14644 and Federal Standard 209E, ensuring compliance and meeting the required classification level.

Layout and Space Optimization: The cleanroom layout is meticulously planned to maximize space utilization, minimize cross-contamination risks, and provide ergonomic workstations.

HVAC Systems: The heating, ventilation, and air conditioning (HVAC) systems are customized to maintain strict temperature, humidity, and pressure control within the cleanroom, ensuring optimal conditions for sensitive processes.

Applications of BioSafe Stainless Steel Modular Cleanrooms

The BioSafe Stainless Steel Modular Cleanroom finds application in various industries:

Pharmaceuticals and Biotechnology: The cleanroom provides a controlled environment for drug manufacturing, compounding, and research, ensuring product integrity and patient safety.

Electronics and Semiconductor: The cleanroom safeguards sensitive electronic components from contaminants during manufacturing, assembly, and testing processes.

Healthcare and Hospitals: BioSafe Stainless Steel Modular Cleanrooms are utilized in hospitals and healthcare facilities for sterile compounding, surgical procedures, and research.

Research and Development: Research laboratories rely on cleanrooms for precise experiments, material testing, and advanced scientific research.

Youth Modular Cleanroom’s Features:

- Our design process includes real-time simulation and calculation of the entire room wall panels using advanced 3D design software.

- The ground keel is constructed using sturdy 95954 square tubes, which are pre-embedded with concrete for enhanced stability.

- Tight support between wall panels is achieved through the use of rectangular tubes, ensuring a secure and robust structure.

- YOUTH offers a unique JH-100 reinforced wall panel, which can undergo full welding treatment for added strength and durability.

- The special roof design includes prefabricated air openings with air outlets to facilitate proper ventilation within the room.

- To ensure a seamless and polished finish, the interior of the room features arc corners that neatly close the edges.

- The room is compatible with YOUTH’s airtight doors and mechanical doors, allowing for easy installation and ensuring optimal air containment.

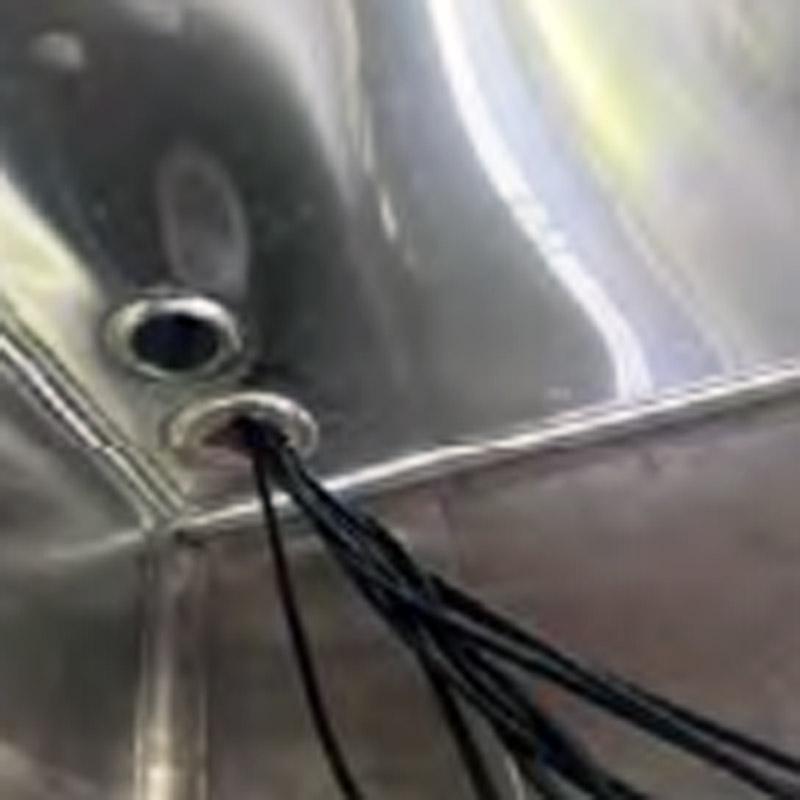

Sealed connection to the bag-in-bag-out system: The cleanroom is equipped with a sealed connection that allows for the safe handling of contaminated materials, ensuring proper containment and preventing any potential exposure to harmful substances.

Sealed connection with the scanning leak detection mechanism: To maintain the integrity of the cleanroom, a sealed connection is established with a scanning leak detection mechanism. This ensures that any potential leaks are quickly identified and addressed, maintaining a controlled and sterile environment.

A tight connection with a through-wall seal: The cleanroom incorporates a tight connection with a through-wall seal, ensuring a secure and airtight barrier between the cleanroom and external areas. This prevents the ingress of contaminants and maintains the cleanliness of the controlled environment.

Sealed connection to VHP Pass Box: A sealed connection is established with a VHP (Vaporized Hydrogen Peroxide) Pass Box, allowing for the safe transfer of materials into and out of the cleanroom. This connection ensures that the cleanroom remains protected from any potential contamination during material transfer processes.

Sealed connections to biosafety airtight doors: The BioSafe Stainless Steel Modular Cleanroom features sealed connections with biosafety airtight doors. These doors provide an additional layer of containment, preventing the escape of hazardous substances and maintaining the sterility of the cleanroom environment.

Quality Standards and Certifications

YOUTH ensures that the BioSafe Stainless Steel Modular Cleanroom adheres to the highest quality standards and has obtained relevant certifications. These certifications may include ISO 14644, cGMP, FDA, and CE, guaranteeing the cleanroom’s performance and compliance with industry regulations.

Maintenance and Cleaning of BioSafe Stainless Steel Modular Cleanrooms

Proper maintenance and regular cleaning are vital to preserving the integrity and cleanliness of the BioSafe Stainless Steel Modular Cleanroom. YOUTH recommends the following best practices:

Routine Cleaning Procedures: Establish a cleaning schedule for surfaces, equipment, and air handling units to prevent the buildup of contaminants.

Proper Disinfection Protocols: Use suitable disinfectants and cleaning agents that are compatible with stainless steel surfaces to ensure effective sterilization without causing damage.

Filter Replacement: Regularly replace air filters to maintain optimal air quality and prevent contamination.

Customization Options

YOUTH understands that each business has unique requirements. Therefore, the BioSafe Stainless Steel Modular Cleanroom offers customization options, such as:

Size and Layout: Customize the dimensions and layout of the cleanroom to fit specific space constraints and workflow needs.

Access Points and Pass-Through Chambers: Incorporate designated access points and pass-through chambers to facilitate material transfer while maintaining cleanliness.

Cost-Effectiveness and Return on Investment

Investing in a BioSafe Stainless Steel Modular Cleanroom offers long-term benefits and a solid return on investment. By ensuring product quality, minimizing contamination risks, and meeting regulatory standards, businesses can:

Reduce Product Loss: Prevent contamination-related product loss, ensuring higher product yields and minimizing waste.

Improve Efficiency: Streamline processes, reduce errors, and increase productivity by working in a controlled and optimized cleanroom environment.

FAQs:

Can the BioSafe Stainless Steel Modular Cleanroom be customized to fit our specific needs?

Yes, YOUTH understands that different businesses have unique requirements. The BioSafe Stainless Steel Modular Cleanroom can be customized in terms of size, layout, access points, and pass-through chambers to accommodate your specific space constraints and workflow needs.

What industries can benefit from the BioSafe Stainless Steel Modular Cleanroom?

The BioSafe Stainless Steel Modular Cleanroom is suitable for a wide range of industries. It is commonly utilized in pharmaceuticals, biotechnology, electronics, healthcare, hospitals, and research and development facilities where maintaining a sterile environment is crucial.

How does the BioSafe Stainless Steel Modular Cleanroom ensure compliance with industry standards?

YOUTH ensures that the BioSafe Stainless Steel Modular Cleanroom meets industry-specific cleanliness standards, such as ISO 14644 and Federal Standard 209E. It undergoes rigorous testing and certifications to guarantee compliance with quality and regulatory requirements.

What maintenance procedures are recommended for the BioSafe Stainless Steel Modular Cleanroom?

Proper maintenance and regular cleaning are essential for the BioSafe Stainless Steel Modular Cleanroom. YOUTH recommends routine cleaning procedures, including surface cleaning, equipment maintenance, and regular replacement of air filters to maintain optimal cleanliness and functionality.

Can the BioSafe Stainless Steel Modular Cleanroom integrate with our existing equipment and systems?

Yes, the BioSafe Stainless Steel Modular Cleanroom seamlessly integrates with existing infrastructure. It is designed to be compatible with various equipment and systems, optimizing workflow efficiency and ensuring smooth integration into your operations.

How does the BioSafe Stainless Steel Modular Cleanroom contribute to cost-effectiveness and return on investment?

By investing in the BioSafe Stainless Steel Modular Cleanroom, businesses can reduce product loss due to contamination, improve operational efficiency, and meet regulatory standards. It streamlines processes, increases productivity, and ensures higher product yields, leading to a solid return on investment.

Can the BioSafe Stainless Steel Modular Cleanroom be expanded or reconfigured as our needs evolve?

Absolutely, the modular design of the BioSafe Stainless Steel Modular Cleanroom allows for easy expansion and reconfiguration. As your business grows and requirements change, the cleanroom can be adapted to accommodate new processes and accommodate evolving needs.

What certifications does the BioSafe Stainless Steel Modular Cleanroom hold?

The BioSafe Stainless Steel Modular Cleanroom obtains certifications such as ISO 14644, cGMP, FDA, and CE. These certifications validate the cleanroom’s performance, quality, and compliance with industry regulations.

How does the BioSafe Stainless Steel Modular Cleanroom contribute to product quality and integrity?

The BioSafe Stainless Steel Modular Cleanroom provides a controlled and sterile environment, minimizing the risk of contamination. By maintaining strict air quality, temperature, and humidity control, it ensures the integrity and quality of products, particularly in industries such as pharmaceuticals and electronics.

What is the process of designing and constructing a BioSafe Stainless Steel Modular Cleanroom?

The design and construction process of a BioSafe Stainless Steel Modular Cleanroom involves careful consideration of cleanroom classifications, layout optimization, and HVAC systems customization. YOUTH’s experts work closely with clients to create a tailored cleanroom solution that meets their specific requirements.

How does the BioSafe Stainless Steel Modular Cleanroom contribute to research and development activities?

The BioSafe Stainless Steel Modular Cleanroom is a valuable asset in research and development. It provides a controlled environment for precise experiments, material testing, and advanced scientific research, ensuring the reliability and accuracy of results.

Can the BioSafe Stainless Steel Modular Cleanroom help in minimizing cross-contamination risks?

Yes, the BioSafe Stainless Steel Modular Cleanroom is designed to minimize cross-contamination risks. With its well-planned layout and strategic placement of equipment and workstations, it helps maintain the integrity of processes by preventing the spread of contaminants within the cleanroom environment.

What are the specific features that make the BioSafe Stainless Steel Modular Cleanroom durable?

The BioSafe Stainless Steel Modular Cleanroom is constructed using high-quality stainless steel. This material provides durability, corrosion resistance, and easy cleanability, ensuring the longevity and reliability of the cleanroom structure.

How does YOUTH ensure the air quality within the BioSafe Stainless Steel Modular Cleanroom?

YOUTH incorporates advanced filtration systems and air handling units in the BioSafe Stainless Steel Modular Cleanroom to maintain optimal air quality. These systems effectively remove particles and microorganisms from the air, creating a clean and sterile environment.

Can the BioSafe Stainless Steel Modular Cleanroom be relocated if needed?

Yes, the modular design of the BioSafe Stainless Steel Modular Cleanroom allows for easy relocation. If your business needs to move or reconfigure the cleanroom in a different space, it can be dismantled and rebuilt to ensure continuity in your cleanroom operations.

How does the BioSafe Stainless Steel Modular Cleanroom contribute to regulatory compliance?

By adhering to industry-specific standards and certifications, the BioSafe Stainless Steel Modular Cleanroom ensures regulatory compliance. It provides businesses with a reliable solution to meet the strict cleanliness requirements set by regulatory bodies, such as the FDA and cGMP.

What are the advantages of choosing stainless steel construction for the cleanroom?

Stainless steel construction offers several advantages for the BioSafe Stainless Steel Modular Cleanroom. It provides a durable and clean surface, resists corrosion, is easy to maintain, and withstands frequent cleaning and sterilization procedures without compromising its structural integrity.

Can YOUTH provide installation and ongoing support for the BioSafe Stainless Steel Modular Cleanroom?

Yes, YOUTH offers comprehensive support throughout the entire process, from design to installation and ongoing maintenance of the BioSafe Stainless Steel Modular Cleanroom. Our experienced team ensures a seamless transition and provides reliable support to meet your cleanroom needs.

How can businesses get in touch with YOUTH to discuss their cleanroom requirements?

Businesses can easily get in touch with YOUTH by visiting our website or contacting our customer support. Our dedicated team is ready to listen to your requirements, provide expert guidance, and offer customized solutions to meet your cleanroom needs.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- The Cleanroom Experience: A Guide to Safe and Efficient Operations

- Fan Filter Units: Key to Quality Control in Cleanroom Manufacturing Processes

- The Ultimate Guide to YOUTH Modular Cleanrooms: Precision, Flexibility, and Efficiency

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification

- Achieving Precision and Cleanliness: The Power of Fan Filter Units

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Fan Filter Units: Ensuring Sterile Conditions in Cleanroom Environments

- Understanding the Mechanics of Fan Filter Units: A Detailed Guide