YOUTH Laminar Airflow Unit – LAF for Cleanroom

What is Laminar Air Flow for Cleanroom?

Laminar Air Flow for cleanrooms refers to a controlled and specialized airflow system that is designed to maintain a consistent and uniform flow of clean air within an enclosed environment, such as a cleanroom or controlled laboratory space. This airflow system plays a crucial role in minimizing the presence of airborne particles, contaminants, and microorganisms, thereby ensuring a sterile and controlled environment that is essential for industries such as pharmaceuticals, biotechnology, electronics manufacturing, and healthcare.

Key features and aspects of Laminar Air Flow for cleanrooms include:

Unidirectional Airflow:

Laminar Air Flow creates a unidirectional airflow pattern where air moves in a straight, parallel path from a high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filter located at the rear or top of the cleanroom down to the floor or work surface.

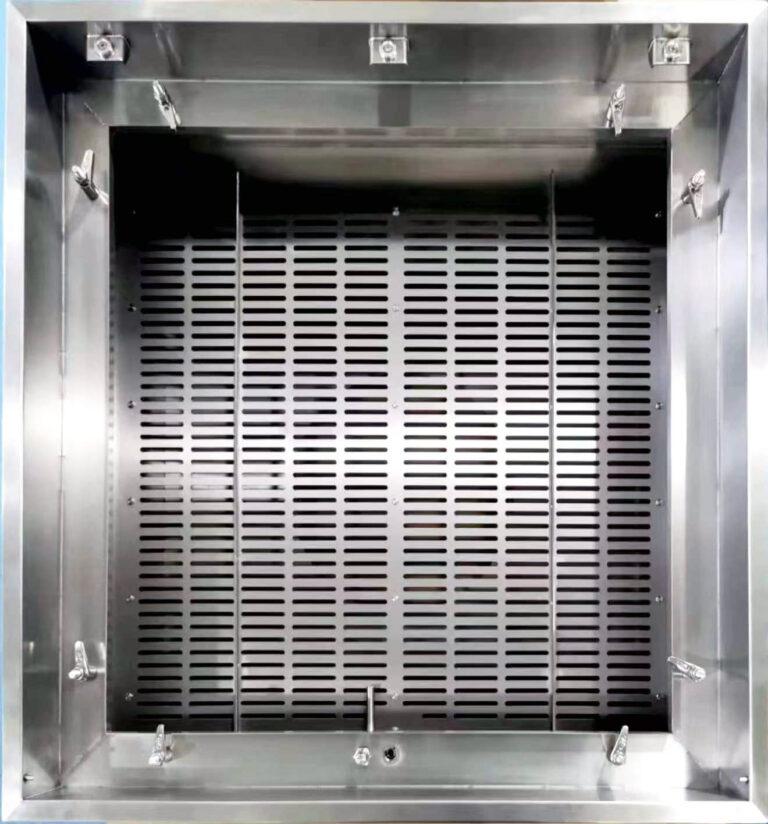

HEPA/ULPA Filters:

These filters are capable of removing particles as small as 0.3 microns with high efficiency, ensuring that the air entering the cleanroom is virtually free from contaminants.

Horizontal and Vertical Laminar Flow:

There are two main configurations of Laminar Air Flow: horizontal and vertical. Horizontal flow directs air across the workspace, while vertical flow directs air downward onto the work surface.

Clean Air Envelopes:

Laminar Air Flow creates clean air envelopes around workstations, equipment, or products, effectively isolating them from the surrounding environment.

Contamination Control:

The controlled and consistent airflow helps prevent the introduction and spread of contaminants, particles, and microorganisms, crucial in environments requiring high levels of cleanliness.

Personnel Protection:

Laminar Air Flow systems can also be used in biological safety cabinets and fume hoods to protect personnel from exposure to hazardous materials.

Positive or Negative Pressure:

Depending on the requirements, Laminar Air Flow systems can maintain positive or negative pressure within the cleanroom to prevent the entry or exit of contaminants.

Critical Areas:

Laminar Air Flow is often used in critical areas such as sterile processing rooms, research laboratories, and manufacturing facilities where maintaining a controlled environment is essential.

Uniformity and Efficiency:

The consistent airflow pattern ensures uniformity of conditions across the cleanroom space, enhancing the reliability and accuracy of processes.

Laminar Air Flow systems are vital tools for industries where strict cleanliness, sterility, and contamination control are paramount. They contribute significantly to creating and maintaining controlled environments that meet the rigorous standards and regulatory requirements of various sectors.