What is a LAF?

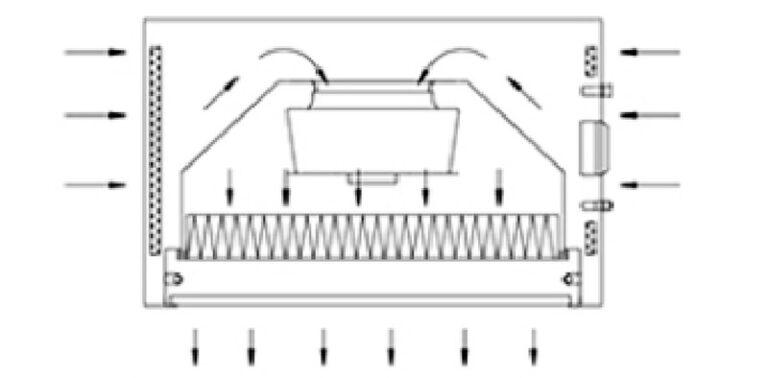

A-Class laminar air flow hood is a controlled airflow system used in healthcare, pharmaceuticals, electronics, and research labs. It ensures a sterile environment by creating a unidirectional flow of clean, filtered air with minimal turbulence. LAF systems can be vertical or horizontal and require regular maintenance and monitoring, it utilizes HEPA or ULPA filters to remove particles and contaminants.

YOUTH‘s LAF Features

- Double-layer negative pressure structure prevents frame edge and joint leakage.

- Uniform airspeed on the air outlet surface.

- Offers flexible return air methods.

- Room air can be retrieved from the side.

- Can be connected to a duct for outside air intake, reducing cleanliness interference.

- High-quality raw materials from domestic and international sources for filters.

- Strong, efficient, and water/oil-resistant filter paper.

- Precise production line with strict quality control measures.

- Filters undergo leak detection before leaving the factory to meet efficiency and resistance standards.

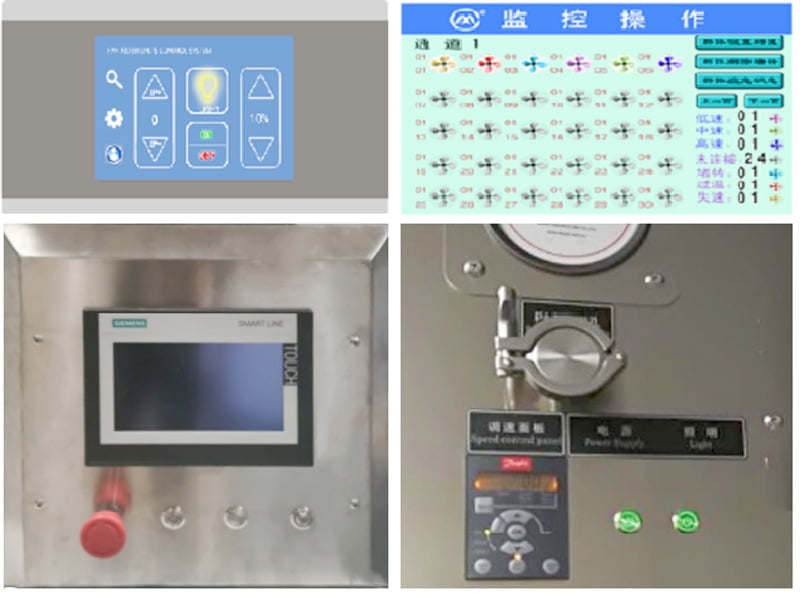

- Diverse control options to cater to varying customer needs.

- TRIAC, frequency converter, PLC control, and touch screen group control available.

- Customizable enclosure options for added flexibility.

- High air pressure and energy efficiency: Equipped with an aluminum impeller that enhances airflow while maintaining energy efficiency.

- Low noise operation: The imported EBM fan ensures a quiet performance, contributing to a peaceful environment.

- Reliable performance: The fan’s aluminum impeller design promotes consistent and reliable operation over time.

Movable uniform PET diffuser or stainless steel diffuser plate ensures even air velocity distribution in the space.

Varieties, Installation, and Uses

The laminar flow hood can be categorized into two types: one with an internal fan and the other with an external fan. It serves for indoor exhaust-side air intake as well as utilizing HVAC systems for top air intake. It can be installed either as a suspended unit or with a floor stand, suitable for both individual and combined use. Furthermore, it can be further classified based on specific application scenarios, air quality standards, and performance attributes.

Applications

- In healthcare, LAF is vital for surgical procedures, reducing the risk of infections by maintaining a sterile field.

- Pharmaceutical and biotech industries rely on LAF to protect sensitive products during manufacturing and testing.

- In electronics manufacturing, LAF safeguards components from dust and static charges.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Mastering Clean Room Technology with Fan Filter Units (FFUs)

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- A Comprehensive Guide to Indoor Air Quality (IAQ)

- Navigating Biosafety Cabinet Classes: A Complete Overview

- How-to guide: Pass box qualification

- HORIZONTAL VS. VERTICAL LAMINAR FLOW Units: WHAT’S THE DIFFERENCE?

- Comprehensive Guide on Biological Safety Cabinets: Ensuring Laboratory Safety and Integrity

- Comprehensive Guide to Biosafety Cabinets: Safeguarding Research and Laboratories