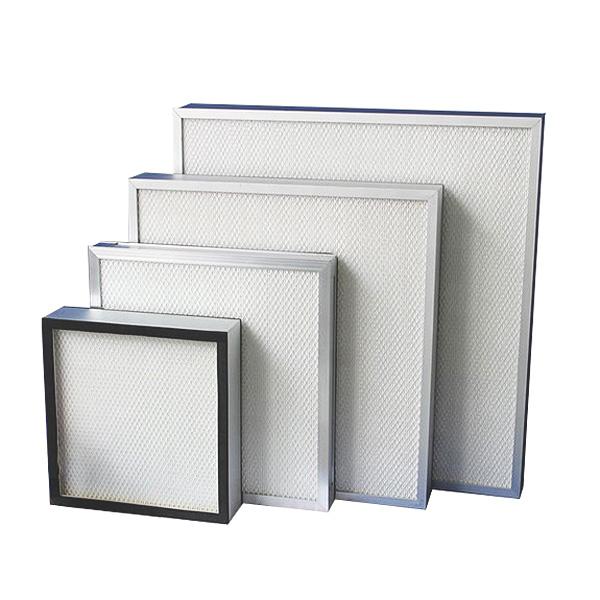

YOUTH High-Efficiency Air Filter for Cleanroom

What is High-Efficiency Air Filter for Cleanroom?

A High-Efficiency Air Filter for cleanrooms, often referred to as HEPA (High-Efficiency Particulate Air) filter, is a specialized filtration device designed to remove airborne particles and contaminants from the air in controlled environments, such as cleanrooms, laboratories, and healthcare facilities. HEPA filters are crucial components in maintaining the cleanliness, sterility, and quality of the air within these sensitive environments.

Key characteristics and features of High-Efficiency Air Filters for cleanrooms include:

Particle Removal:

HEPA filters are engineered to capture particles as small as 0.3 micrometers in diameter with a high efficiency, typically around 99.97%. This includes a wide range of particles such as dust, allergens, bacteria, viruses, and other microscopic particles.

Construction:

HEPA filters consist of a dense arrangement of randomly oriented fibers made from materials such as glass, fiberglass, or synthetic materials. The fibers create a maze-like structure that traps particles as air passes through.

Filtration Mechanism:

Particles are captured through a combination of diffusion, interception, and impaction as they collide with the fibers in the filter. This mechanism ensures a high level of filtration efficiency.

Clean Air Delivery Rate (CADR):

HEPA filters are characterized by their CADR, which indicates the volume of clean air they can deliver per unit of time. This metric is crucial for assessing the effectiveness of the filter in specific applications.

Applications:

HEPA filters are used in a wide range of applications, including pharmaceutical manufacturing, semiconductor production, healthcare facilities, laboratories, cleanrooms, and environments requiring high levels of cleanliness and air quality.

Variants:

There are variations of HEPA filters, such as ULPA (Ultra-Low Penetration Air) filters, which offer even higher filtration efficiency, often exceeding 99.9999% for particles as small as 0.12 micrometers.

Installation:

HEPA filters are installed in air handling systems, laminar flow hoods, cleanroom ceilings, and other equipment where maintaining clean air quality is essential.

Certification:

HEPA filters are subject to stringent testing standards and must meet specific criteria to be certified as true HEPA filters. They are often tested and certified according to standards such as EN 1822 or the Institute of Environmental Sciences and Technology (IEST) standards.

Replacement:

Regular replacement of HEPA filters is necessary to maintain their effectiveness. Filter replacement schedules depend on factors such as usage, the cleanliness of the environment, and the type of particles being filtered.

In summary, a High-Efficiency Air Filter (HEPA filter) for cleanrooms is a critical component for maintaining air quality and cleanliness in controlled environments. By effectively capturing a wide range of airborne particles, these filters contribute to creating a safe and contamination-free atmosphere, supporting various industries that demand stringent cleanliness and sterility standards.