What is a cleanroom bag&pocket medium-efficiency air filter?

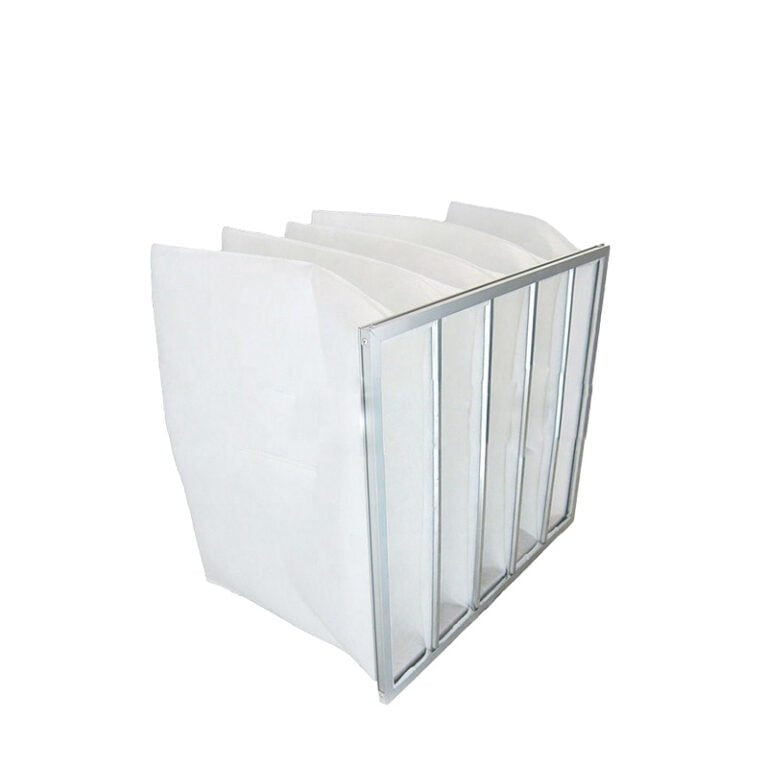

Cleanroom bag&pocket medium-efficiency air filters are specialized air filters designed for use in cleanroom environments. They are typically made of high-quality synthetic media that effectively captures airborne particles and contaminants, preventing them from entering the cleanroom space. These filters are available in bag or pocket configurations, which allow for a large filtration area, resulting in higher dust-holding capacity and longer filter life.

The bag-type air filter has 3-12 parallel bags, and the bag depth is generally 250~900mm. Ultrasonic welding between individual bags. Such a process ensures that the airflow can pass through the entire filter more efficiently and the dust is efficiently loaded and evenly distributed. This extends filter life and reduces energy costs. And a grid can be arranged in the inner bag of the filter to effectively increase the filtering area.

How do bag&pocket medium-efficiency air filters work?

Cleanroom bag&pocket medium-efficiency air filters work based on the principle of mechanical filtration. The synthetic media used in these filters is designed with varying fiber diameters and layers to create a tortuous path for the air to pass through. This traps and retains particles of different sizes, including dust, pollen, mold spores, bacteria, and other airborne contaminants. The filters typically have a high initial efficiency and are capable of achieving an average efficiency of 60-90% for particles in the range of 1-10 microns, depending on the filter class.

| Type: | BF-F7 | BF-F8 | BF-F9 |

| Class EN779 | F7 | F8 | F9 |

| Average efficiency (Em) for 0.4µm particles | 80% ≤ Em < 90% | 90% ≤ Em < 95% | 95% ≤ Em |

| Initial-ΔP [Pa] at nominal airflow | 110 | 120 | 185 |

Model (D=depth/E=efficiency) | Dimension [mm] | Nominal airflow [m3/h] | Pockets quantity | |||

| Width | Height | Depth 300 [mm] | Depth 500 [mm] | Depth 650 [mm] | ||

| BF592592D-E (F7-F9) | 592 | 592 | 1570 | 2620 | 3400 | 8 |

| BF490592D-E (F7-F9) | 490 | 592 | 1300 | 2160 | 2800 | 6 |

| BF287592D-E (F7-F9) | 287 | 592 | 790 | 1210 | 1700 | 4 |

| BF287287D-E (F7-F9) | 287 | 287 | 400 | 660 | 850 | 4 |

| BF592892D-E (F7-F9) | 592 | 892 | 2360 | 3930 | 5100 | 8 |

| BF287892D-E (F7-F9) | 287 | 892 | 1180 | 1970 | 2550 | 4 |

| Customized Available from 1-12. | ||||||

How do bag&pocket medium-efficiency air filters work?

Cleanroom bag&pocket medium-efficiency air filters work based on the principle of mechanical filtration. The synthetic media used in these filters is designed with varying fiber diameters and layers to create a tortuous path for the air to pass through. This traps and retains particles of different sizes, including dust, pollen, mold spores, bacteria, and other airborne contaminants. The filters typically have a high initial efficiency and are capable of achieving an average efficiency of 60-90% for particles in the range of 1-10 microns, depending on the filter class.

What are the Features and benefits of cleanroom bag&pocket medium-efficiency air filters?

Cleanroom bag&pocket medium-efficiency air filters offer several unique features and benefits that make them ideal for cleanroom:

High dust-holding capacity: Cleanroom bag&pocket medium-efficiency air filters have a large filtration area, which allows for high dust-holding capacity, resulting in longer filter life and reduced maintenance frequency.

Low pressure drop: These filters have a low-pressure drop, which means they do not impede airflow significantly, resulting in energy savings and reduced operating costs.

Efficient particle capture: Cleanroom bag&pocket medium-efficiency air filters are designed to efficiently capture airborne particles of various sizes, ensuring a high level of air quality in cleanroom environments.

Customizable options: These filters are available in various sizes and configurations, making them suitable for different applications and requirements.

Cost-effective: Compared to high-efficiency filters, cleanroom bag&pocket medium-efficiency air filters are a cost-effective option that provides adequate air quality for many cleanroom applications.

What are the Applications of bag&pocket medium-efficiency air filters?

Cleanroom bag&pocket medium-efficiency air filters are commonly used in various industries and environments, including:

Pharmaceuticals and biotechnology: Cleanroom environments in these industries require high levels of air quality to prevent contamination of sensitive products and equipment.

Microelectronics and semiconductor manufacturing: These industries require cleanroom environments to maintain the purity of electronic components and prevent defects caused by airborne particles.

Food and beverage: Cleanroom bag&pocket medium-efficiency air filters are used to maintain air quality in food processing and packaging facilities, ensuring food safety and quality.

Healthcare facilities: Hospitals and clinics use cleanroom bag&pocket medium-efficiency air filters to maintain a sterile environment in operating rooms, isolation wards, and other critical areas.

How to consider when selecting cleanroom bag&pocket medium-efficiency air filters?

When choosing cleanroom bag&pocket medium-efficiency air filters, there are several factors to consider, including:

Filtration efficiency: The filtration efficiency of the filter should match the requirements of the cleanroom environment.

Filter size and configuration: The filter size and configuration should be selected based on the airflow rate and available space in the cleanroom.

Pressure drop: The pressure drop across the filter should be low to ensure minimal energy consumption and operating costs.

Maintenance requirements: The maintenance requirements of the filter should be considered to ensure cost-effectiveness and optimal performance.

How to Proper maintenance and replacement of bag&pocket medium-efficiency air filters?

To ensure the effective functioning of cleanroom bag&pocket medium-efficiency air filters, proper maintenance and replacement procedures must be followed. This includes:

Regular inspection of the filters to assess their condition and dust-holding capacity.

Replacing the filters when they reach their recommended replacement interval or when they reach their maximum dust-holding capacity.

Cleaning the filter housing and surrounding area to prevent contamination of the cleanroom environment.

What is the difference from other types of air filters?

Cleanroom bag&pocket medium-efficiency air filters are often compared to other types of air filters, including high-efficiency particulate air (HEPA) filters and low-efficiency filters. Compared to HEPA filters, cleanroom bag&pocket medium-efficiency air filters have a lower initial cost and are suitable for many cleanroom applications that do not require the highest level of air purity. Compared to low-efficiency filters, cleanroom bag&pocket medium-efficiency air filters provide superior air quality and have a longer filter life.

FAQs

Can cleanroom bag&pocket medium-efficiency air filters be used in any cleanroom environment?

Cleanroom bag&pocket medium-efficiency air filters are suitable for many cleanroom environments, including those in the pharmaceutical, biotechnology, microelectronics, semiconductor manufacturing, food and beverage, and healthcare industries. However, the selection of the filter depends on the specific requirements of the cleanroom environment. It is recommended to consult with a qualified professional to determine the best filter for your application.

How often should cleanroom bag&pocket medium-efficiency air filters be replaced?

The replacement frequency of cleanroom bag&pocket medium-efficiency air filters depends on various factors, including the level of air pollution, the airflow rate, and the recommended replacement interval provided by the manufacturer. Generally, these filters need to be replaced every 3 months to 1 year. It is recommended to inspect the filter regularly to assess its condition and dust-holding capacity and replace it when necessary.

Are cleanroom bag&pocket medium-efficiency air filters easy to install and maintain?

Yes, cleanroom bag&pocket medium-efficiency air filters are easy to install and maintain. They come in various sizes and configurations, making them suitable for different applications and requirements. The maintenance procedure involves regular inspection of the filter, replacement when necessary, and cleaning of the filter housing and surrounding area. It is recommended to follow the manufacturer’s guidelines for installation and maintenance.

How do I know if my cleanroom bag&pocket medium-efficiency air filter needs to be replaced?

You can assess the condition of the cleanroom bag&pocket medium-efficiency air filter by inspecting its dust-holding capacity. If the filter is clogged with dust and debris, it may need to be replaced. Additionally, a significant increase in pressure drop across the filter indicates that it may be nearing the end of its life cycle. It is recommended to follow the manufacturer’s recommended replacement interval and inspect the filter regularly to ensure optimal performance.

How do cleanroom bag&pocket medium-efficiency air filters compare to other types of air filters?

Cleanroom bag&pocket medium-efficiency air filters are a cost-effective option that provides adequate air quality for many cleanroom applications. Compared to high-efficiency particulate air (HEPA) filters, cleanroom bag&pocket medium-efficiency air filters have a lower initial cost and are suitable for applications that do not require the highest level of air purity. Compared to low-efficiency filters, cleanroom bag&pocket medium-efficiency air filters provide superior air quality and have a longer filter life. However, the selection of the filter depends on the specific requirements of the cleanroom environment, and it is recommended to consult with a qualified professional to determine the best filter for your application.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- Mastering Clean Room Technology with Fan Filter Units (FFUs)

- Mastering Air Filter Selection: A Comprehensive Guide

- A Comprehensive Guide to Indoor Air Quality (IAQ)

- Fan Filter Units: Balancing Efficiency and Cost-Effectiveness

- Fan Filter Units: Key to Quality Control in Cleanroom Manufacturing Processes

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification