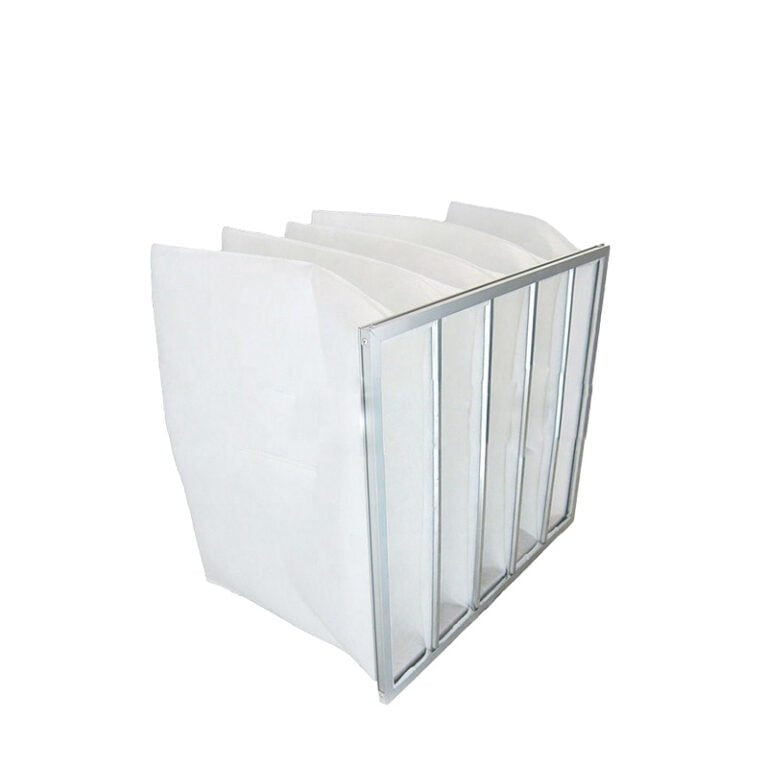

What are Cleanroom Bag&Pocket pre-air filters?

Cleanroom Bag&Pocket pre air filter is a type of air filter that removes contaminants and particles from the air. It is typically installed in HVAC systems to prevent pollutants from entering the system and recirculating into the air.

How do Cleanroom Bag&Pocket pre air filter work?

Cleanroom Bag&Pocket pre air filter works by using a dense, fibrous material to trap particles and pollutants from the air. As air passes through the filter, it captures particles such as dust, pollen, and other airborne contaminants. The filter media is designed to be highly effective in capturing small particles, including bacteria and viruses.

How many Types of Cleanroom Bag&Pocket pre air filter?

Cleanroom Bag&Pocket pre air filter comes in various types, including polyester, fiberglass, pleated, and high-efficiency particulate air (HEPA) filters. Polyester filters are ideal for capturing small particles, while fiberglass filters are suitable for capturing larger particles. Pleated filters offer a high surface area for capturing pollutants, and HEPA filters are highly effective in removing ultrafine particles.

What are the Advantages of using a Bag&Pocket pre-air filter?

Reduces contamination risks – Cleanroom Bag&Pocket pre air filter helps reduce the risks of contamination by removing pollutants and particles from the air. This is especially important in environments where there is a need to maintain high levels of cleanliness and hygiene, such as hospitals, laboratories, and cleanrooms.

Improves indoor air quality – Cleanroom Bag&Pocket pre air filter helps improve indoor air quality by removing pollutants and particles from the air. This is especially important for people with allergies or respiratory issues who are more sensitive to airborne pollutants.

Increases HVAC system efficiency – Cleanroom Bag&Pocket pre air filter helps increase HVAC system efficiency by preventing pollutants from entering the system and clogging up the filters. This results in lower energy costs and longer lifespan of the HVAC system.

How to choose the right Bag&Pocket pre-air filter?

Consider the MERV rating – The Minimum Efficiency Reporting Value (MERV) rating measures the effectiveness of a filter in removing particles from the air. The higher the MERV rating, the more effective the filter is in capturing smaller particles. It is important to choose the right MERV rating depending on your needs and the environment. For example, a MERV rating of 8-11 is suitable for residential use, while a MERV rating of 13-16 is ideal for commercial and industrial use.

Look for the right size – It is essential to choose the right size of Cleanroom Bag&Pocket pre air filter for your HVAC system. A filter that is too small will not be effective in capturing pollutants, while a filter that is too large will not fit properly in the system. To determine the right size, consult the manufacturer’s recommendations or consult with an HVAC professional.

Determine the filter type – The type of Cleanroom Bag&Pocket pre air filter depends on the needs of your environment. Polyester and fiberglass filters are suitable for capturing larger particles, while pleated filters are ideal for capturing smaller particles. HEPA filters are highly effective in removing ultrafine particles and are suitable for use in environments where a high level of cleanliness is required.

How to Installation and maintenance of Cleanroom Bag&Pocket pre air filter?

Proper installation techniques – Proper installation of Cleanroom Bag&Pocket pre air filter is crucial for optimal performance. Ensure that the filter fits properly in the system and that there are no gaps or leaks. Follow the manufacturer’s instructions or consult with an HVAC professional for proper installation techniques.

Frequency of replacement – The frequency of Cleanroom Bag&Pocket pre air filter replacement depends on several factors, including the MERV rating, the environment, and the level of usage. It is recommended to replace the filter every 1-3 months for residential use and every 6-12 months for commercial and industrial use.

Maintenance tips – Regular maintenance of Cleanroom Bag&Pocket pre air filter is essential for optimal performance. Check the filter regularly for signs of wear and tear, damage, or clogging. Clean or replace the filter as needed, and follow the manufacturer’s instructions for proper maintenance techniques.

What are the Common mistakes to avoid when using Cleanroom Bag&Pocket pre-air filter?

Some common mistakes to avoid when using Cleanroom Bag&Pocket pre air filter include using the wrong size or MERV rating, not replacing the filter regularly, and not following proper installation and maintenance techniques. Avoid these mistakes to ensure optimal performance and longevity of the filter and the HVAC system.

| Type | BF-G3 | BF-G4 | BF-M5 | BF-M6 |

| Class EN779 | G3 | G4 | M5 | M6 |

| Arrestance EN779 [%] | >86% | >91% | >96% | >98% |

| Efficiency EN779 [%] | >25% | >35% | >55% | >65% |

| Initial-ΔP [Pa] at nominal airflow | 30 | 35 | 45 | 50 |

Model (E=efficiency) | Dimensions [mm] | Nominal airflow [m³/h] | Pockets quantity | |||

| Width | Height | Depth 200 [mm] | Depth 360 [mm] | Depth 500 [mm] | ||

| BF592592D-E (G3/G4) | 592 | 592 | 1900 | 3400 | 4700 | 6 |

| BF287592D-E (G3/G4) | 490 | 592 | 1600 | 2800 | 4000 | 5 |

| BF287287D-E (G3/G4) | 287 | 592 | 900 | 1700 | 2300 | 3 |

| BF592592D-E (M5/M6) | 287 | 287 | 500 | 950 | 1300 | 3 |

| BF287592D-E (M5/M6) | 592 | 892 | 2700 | 4900 | 6000 | 6 |

| BF287287D-E (M5/M6) | 287 | 892 | 1400 | 2400 | 3000 | 3 |

| Bag Air Filter Customized Available from 1-12. | ||||||

FAQs

What is the difference between Bag&Pocket pre-air filters and other types of air filters?

Cleanroom Bag&Pocket pre-air filter is designed specifically for environments where a high level of cleanliness is required, such as hospitals, laboratories, and cleanrooms. It is highly effective in capturing small particles, including bacteria and viruses, and reducing the risks of contamination.

How often should I replace my Cleanroom Bag&Pocket pre air filter?

The frequency of replacement depends on several factors, including the MERV rating, the environment, and the level of usage. It is recommended to replace the filter every 1-3 months for residential use and every 6-12 months for commercial and industrial use.

Can I clean and reuse Cleanroom Bag&Pocket pre air filter?

No, Cleanroom Bag&Pocket pre air filter is not designed to be cleaned and reused. Once the filter becomes clogged with particles, it must be replaced with a new one.

Can I use a higher MERV rating filter than what is recommended for my HVAC system?

No, it is not recommended to use a higher MERV rating filter than what is recommended for your HVAC system. A filter with a higher MERV rating may not fit properly in the system or may cause airflow problems, reducing the efficiency of the HVAC system.

What is the difference between a HEPA filter and a Cleanroom Bag&Pocket pre air filter?

A HEPA filter is a type of high-efficiency air filter that can capture 99.97% of particles as small as 0.3 microns. Cleanroom Bag&Pocket pre-air filter is designed specifically for environments where a high level of cleanliness is required, but it may not be as effective as a HEPA filter in capturing ultrafine particles.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- Mastering Clean Room Technology with Fan Filter Units (FFUs)

- A Comprehensive Guide to Indoor Air Quality (IAQ)

- Fan Filter Units: Balancing Efficiency and Cost-Effectiveness

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Mastering Air Filter Selection: A Comprehensive Guide