What is a Cleanroom Mini-Pleat HEPA Air Filter?

A mini pleat HEPA/ULPA air filter is a type of air filter that is designed for use in cleanrooms and other controlled environments. HEPA (High-Efficiency Particulate Air) filters and ULPA (Ultra-Low Particulate Air) filters are air filters that are able to remove 99.97% and 99.999% of particles that are 0.3 microns or larger in size, respectively. They are commonly used in cleanrooms and other controlled environments, where they are used to remove particles and contaminants from the air in order to maintain a high level of cleanliness.

It is a high-efficiency filter capable of removing very fine particles from the air, including particles as small as 0.3 microns (for HEPA filters) or 0.1 microns (for ULPA filters).

What are the benefits of using a Mini Pleat HEPA air filter?

MiniPleat HEPA/ULPA air filters are often used for intake and recirculation air filtration in cleanrooms and laminar flow hoods with ultra-stringent requirements for clean air and sterility. The employed MiniPleat technology ensures a flow-friendly geometry and equidistant pleats with uniform media velocity and very low-pressure drop.

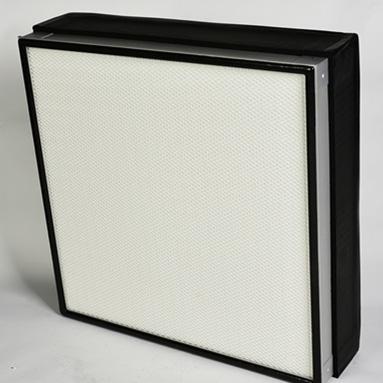

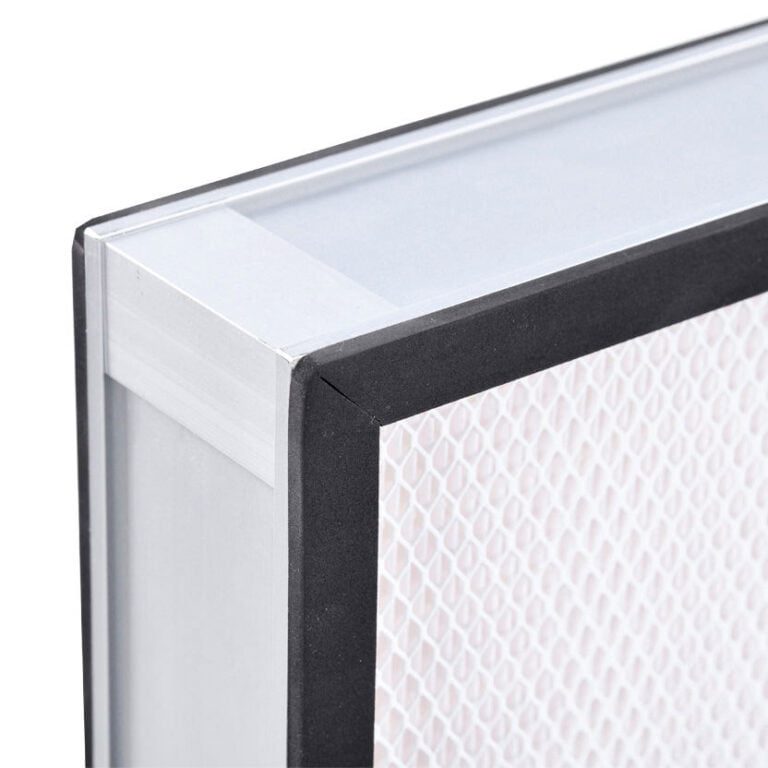

Mini pleat HEPA/ULPA air filters are made by folding the filter media into a series of small pleats, which increases the surface area of the filter and allows it to remove more particles from the air. The pleated filter media is then enclosed within a metal or plastic frame, which is sealed with a plastic or rubber gasket to prevent air leakage. This design allows the filter to remove particles and contaminants from the air while still allowing air to flow through the filter.

What is the Cleanroom Mini Pleat HEPA air filters used for?

Mini pleat HEPA/ULPA air filters are commonly used in cleanrooms and other controlled environments where it is important to maintain a high level of cleanliness. They are typically used in industries that require strict cleanliness standards, such as pharmaceuticals, medical devices, and semiconductors.

How to choose the Mini Pleat HEPA air filters for your project?

When choosing a mini pleat HEPA/ULPA air filter, it is important to consider the specific requirements of your cleanroom, such as the size and shape of the cleanroom, the level of cleanliness required, and the types of hazardous materials that will be used. By carefully evaluating these factors, you can determine the right mini pleat HEPA/ULPA air filter for your needs.

What Are The Features Of The Mini Pleat HEPA Air Filter?

Youth‘s Cleanroom HEPA/ULPA Mini Pleated Air Filters fully seal the filter media within an aluminum frame, completely eliminating air bypass and increasing filtration efficiency. Computer-controlled thermal bead pleat spacing during its manufacture eliminates aluminum corrugated gaskets and minimizes pack depth. While the filter holder is bonded to the media pack for added stiffness, the filter is stronger, more aerodynamic, and reduces filter pressure drop.

The filter’s mini-pleated design enables high air flow rates while maintaining a small footprint, making it ideal for use in cleanrooms where space is limited. Additionally, the pleated design increases the surface area of the filter, allowing it to capture more particles and prolong its life.

How many types of Cleanroom Mini Pleat HEPA air filters?

There are several types of Cleanroom Mini Pleat HEPA air filters available, including:

- Aluminum frame filters – these filters are durable and long-lasting, making them ideal for use in high-traffic areas.

- Galvanized frame filters – these filters are cost-effective and easy to install, making them a popular choice for many applications.

- Stainless steel frame filters – these filters are designed for use in harsh environments and are resistant to corrosion and rust.

| Type | MP-E11 | MP-H13 | MP-H14 | MP-U15 |

| Class EN1822 | E11 | H13 | H14 | U15 |

| Efficiency EN1822@ MPPS [%] | >95 % | >99,95 % | >99,995 % | >99,9995 % |

| Initial-ΔP[Pa]at nominal airflow | 95 | 125 | 160 | 250 |

| Rec. final pressure drop [Pa] | 200 | 300 | 350 | 450 |

| Max. temp. [°C] | 80° | 80° | 80° | 80° |

| Model (E=efficiency) | Width | Height | Depth | Nominal airflow [m3/h] |

| MP61061069-E (E11-U17) | 610 | 610 | 69 | 1000 |

| MP122061069-E (E11-U17) | 1220 | 610 | 69 | 2000 |

| MP117057070-E (E11-U17) | 1170 | 570 | 70 | 1100 |

| MP117087070-E (E11-U17) | 1170 | 870 | 70 | 1750 |

| MP1170117070-E (E11-U17) | 1170 | 1170 | 70 | 2200 |

What are the Applications of Mini Pleat HEPA air filters?

Cleanroom Mini Pleat HEPA air filters are commonly used in a variety of applications, including:

- Cleanrooms – these filters are essential for maintaining a sterile environment in industries such as pharmaceuticals and biotechnology.

- Hospitals and healthcare facilities – Cleanroom Mini Pleat HEPA air filters help to remove harmful airborne particles and prevent the spread of infections.

- Electronics manufacturing – Cleanroom Mini Pleat HEPA air filters prevent dust and other particles from contaminating electronic components, leading to a more reliable product.

How to install the Cleanroom Mini Pleat HEPA Air Filter?

When installing Cleanroom Mini Pleat HEPA air filters, it is essential to ensure that the filter is compatible with the system in which it will be used. The filter should be installed in a location that allows for maximum airflow, and it is important to seal the filter tightly to prevent air from bypassing the filter. It is also important to consider the orientation of the filter, as some filters may be designed to work best in a particular position.

FAQs

How often should Mini Pleat HEPA air filters be cleaned?

Cleanroom Mini Pleat HEPA air filters should be cleaned at least once every three months, depending on the environment in which they are used.

What is the difference between a traditional HEPA filter and a Mini Pleat HEPA air filter?

Cleanroom Mini Pleat HEPA air filters are a more compact version of traditional HEPA filters, designed to fit into smaller spaces while still providing high-efficiency filtration.

What is the lifespan of a Mini Pleat HEPA air filter?

The lifespan of a Cleanroom Mini Pleat HEPA air filter will depend on the environment in which it is used and the level of maintenance it receives. Generally, filters should be replaced when they reach the end of their lifespan or become damaged.

Can Mini Pleat HEPA air filters be used in residential settings?

While Cleanroom Mini Pleat HEPA air filters are commonly used in industrial and healthcare settings, they can also be used in residential settings to improve indoor air quality.

Youth 10,000-level clean workshop

Youth special structure design

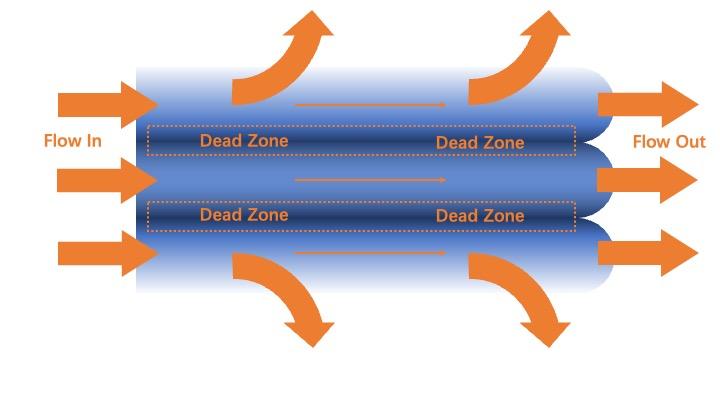

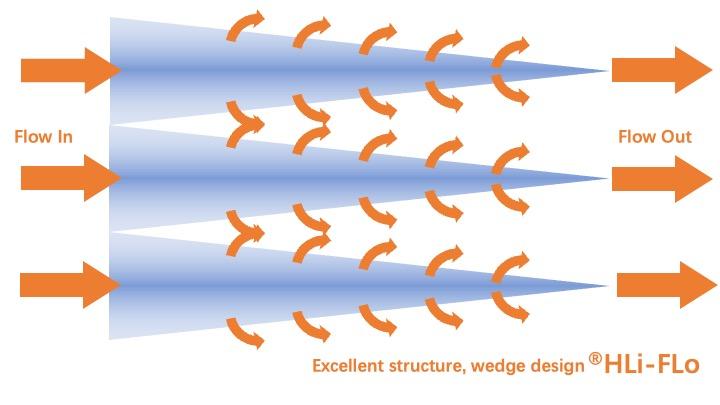

The HEPA air filter designed and produced by Youth Company is a groundbreaking innovation in air filtration technology. Unlike traditional stacked filters, our filter utilizes a unique wedge-shaped structure called the HLi-FLo design, which optimizes the core filtering material for maximum effectiveness.

Our scientific and superior design results in better performance, lower pressure drop, and reduced energy consumption. By utilizing the filter material more efficiently, we can extend the filter’s lifespan and lower the total cost of ownership for our customers. Our product is more efficient and user-friendly, providing a cost-effective solution to clean air.

YOUTH Q&C

HEPA filter material

HEPA filter material

- MPPS inspection

- 100% smoke inspection

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- What are Gel Seal Mini-Pleat HEPA Filters and How to Make the Right Choice?

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs

- Fan Filter Units for Semiconductor Cleanrooms: A Must-Have Solution

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification

- Fan Filter Units: Balancing Efficiency and Cost-Effectiveness

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Fan Filter Units: Key to Quality Control in Cleanroom Manufacturing Processes