What are the Air Filters for Cleanroom?

Cleanroom air filters are intended for use in controlled conditions such as cleanrooms, where air quality is crucial. These filters are used to remove impurities and particles from the air in order to maintain a clean and sanitary atmosphere. They typically have a high-efficiency rate and can collect tiny particles such as bacteria and viruses. Cleanroom air filters are utilized in a range of industries, including pharmaceutical manufacturing, semiconductor manufacturing, and food processing. They can be composed of a range of materials, such as fiberglass, synthetic media, or metal, and are normally classed according to the size of particles they can catch.

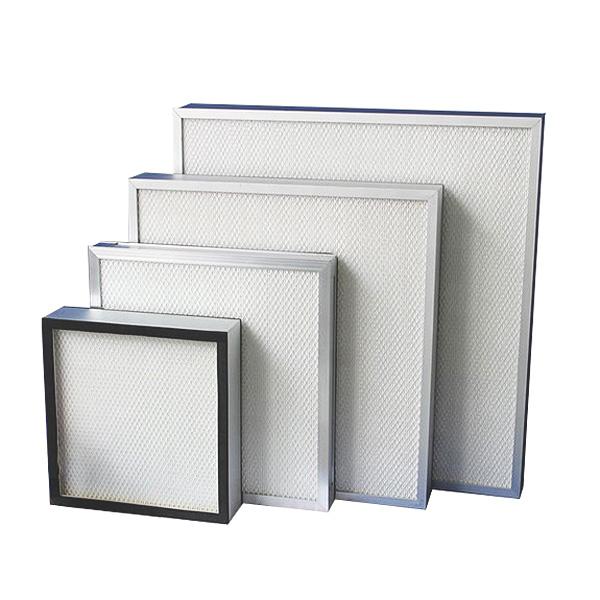

High-Efficiency Air Filters

High-Efficiency Air Filter: Biosafety Purification Equipment is vital for maintaining controlled environments in industries such as biotechnology and pharmaceuticals. It encompasses advanced filters like Mini Pleat HEPA/ULPA, Gel-Seal HEPA/ULPA, HEPA Box / Terminal Diffuser / Terminal Housing, V-Bank HEPA, High-Temp HEPA, and Separator HEPA filters. These filters efficiently remove particles and contaminants, ensuring air quality and sterility essential for critical processes and research. Trust these purification tools for uncompromising cleanliness in your operations.

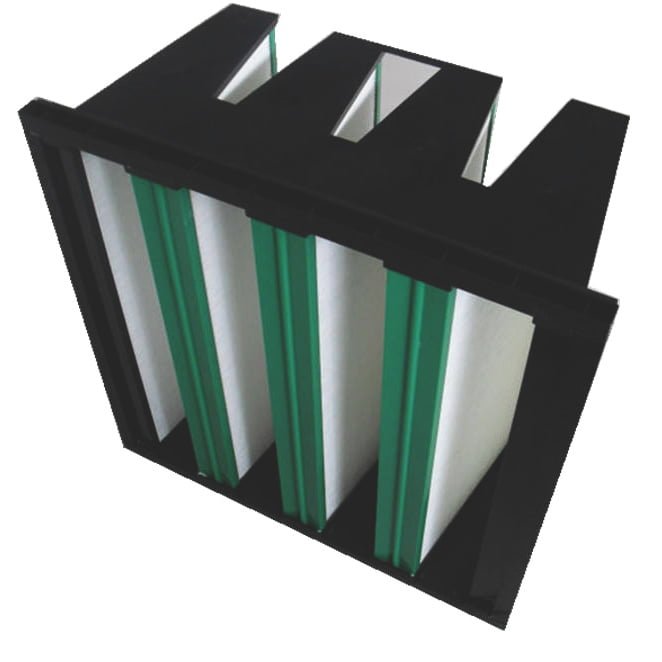

Medium-Efficiency Air Filters

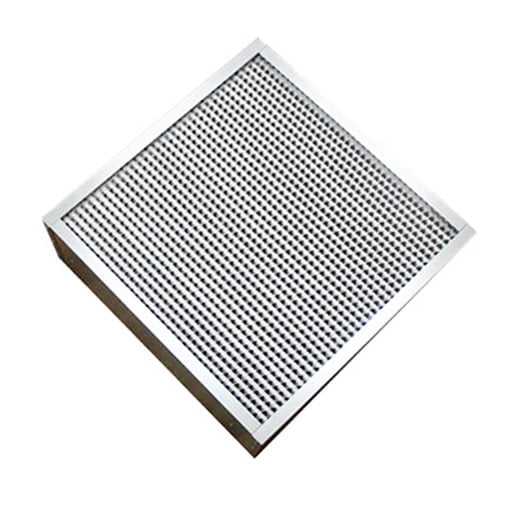

Pre-Air Filters

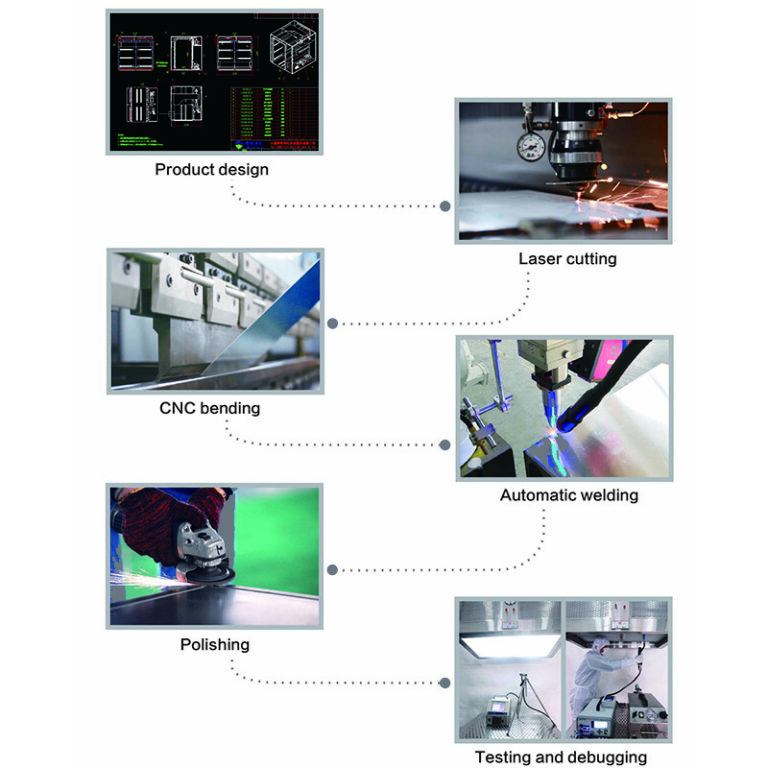

Youth's Feature of Air Filter (Energy-Saving and Cost-Reducing)

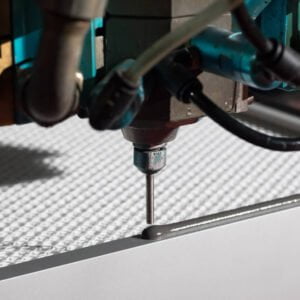

Precision Folding Process: Our imported folding machines guarantee precise folding of HEPA filters. This process ensures stiffness, even spacing, and uniform glue application, resulting in filters with minimal resistance. In comparison to similar products, our filters boast over 15% lower resistance while maintaining top-notch efficiency.

Quality Raw Materials: We source raw materials from the same trusted suppliers as leading global filter brands. Rigorous incoming inspections confirm fine, evenly distributed filter paper fibers, as well as resistance to oil and water. This meticulous sourcing yields filters that deliver consistent airflow and resistance.

Customized Solutions: Our skilled technical team tailors filters to match your specific requirements, enhancing their lifespan. We increase filter surface area for extended use and adjust the filter gradient to optimize each level’s performance. This reduces dust buildup in pipelines, protects HVAC components like evaporators, and significantly reduces the need for frequent filter replacements.

Stringent Testing: Equipped with MPPS testing machines and particle counters, we perform comprehensive integrity testing on filters, meeting customer demands. Every high-efficiency filter undergoes 100% testing before leaving the factory. This ensures that efficiency, airflow, resistance, and leak-free performance all meet stringent quality standards before shipment.