What is a Cleanroom HEPA Housing Box?

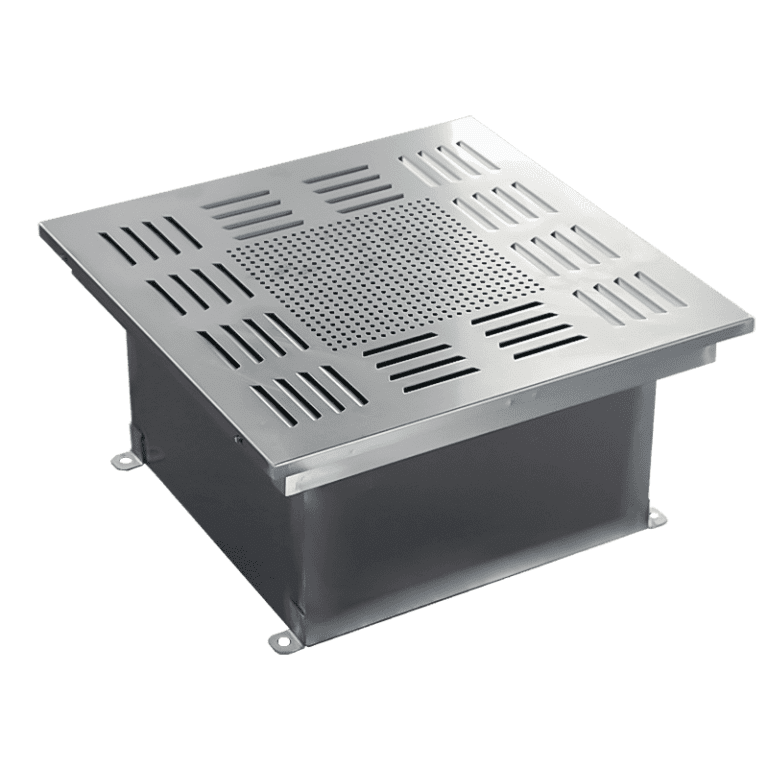

A HEPA Housing Box is a crucial piece of purification equipment used in cleanroom environments. It is designed to house HEPA (High-Efficiency Particulate Air) or ULPA (Ultra-Low Penetration Air) filters, focusing more on the casing itself rather than the filter it holds. This enclosure is typically installed in the ceiling or walls of a cleanroom, providing structural support and maintaining the integrity of the cleanroom’s air filtration system.

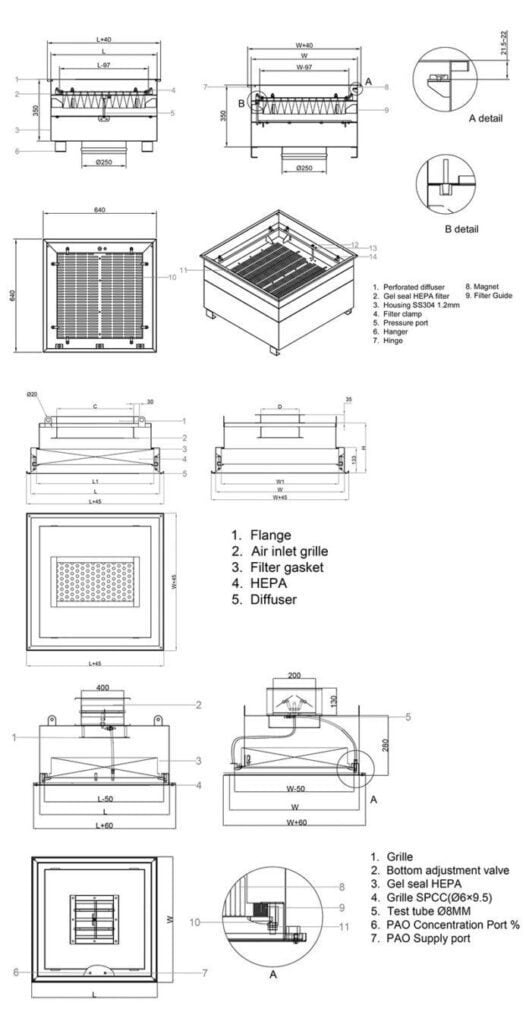

- Perforated Type

- Perforated & Around - Louvers

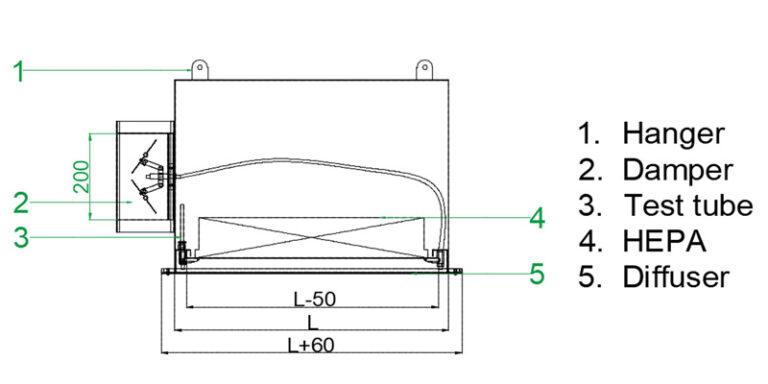

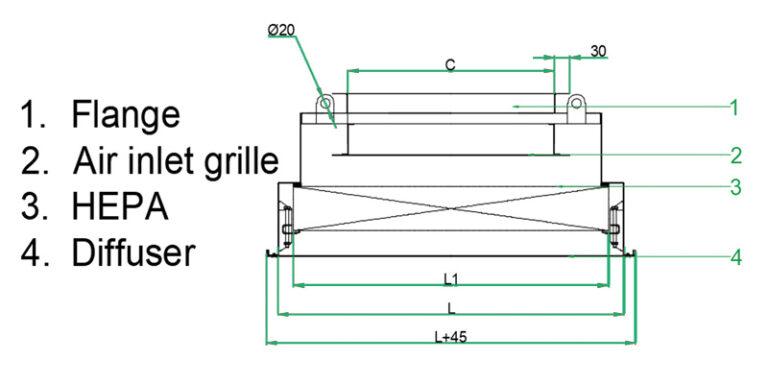

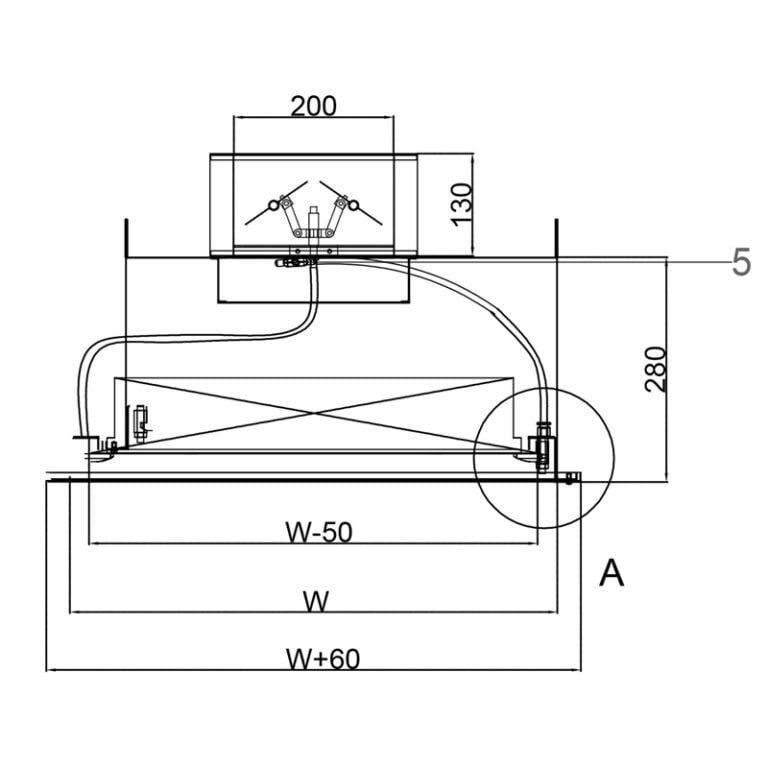

Key components of a cleanroom HEPA Housing Box typically include:

- HEPA filter: This is the core component that captures 99.97% of airborne particles as small as 0.3 microns, ensuring high air purity.

- Housing or casing: A durable enclosure that supports and protects the HEPA filter and ensures leak-free operation.

- Diffuser plate or grille: It evenly distributes the filtered air into the cleanroom, minimizes turbulent airflow, and can help maintain laminar flow.

- Duct connections: For connecting the HEPA Box to the existing HVAC system to guide the air through the filter.

- Gel Seal or Gasket: Ensures a tight seal between the HEPA filter and the housing to prevent bypass and potential contamination.

YOUTH VS Others HEPA Box

Multiple installation methods

- Ducted Ceiling mounted

- Direct placement on the framework

- Embedding using L-shaped supports with screw clamps

YOUTH HEPA Housing Box Customized Solutions

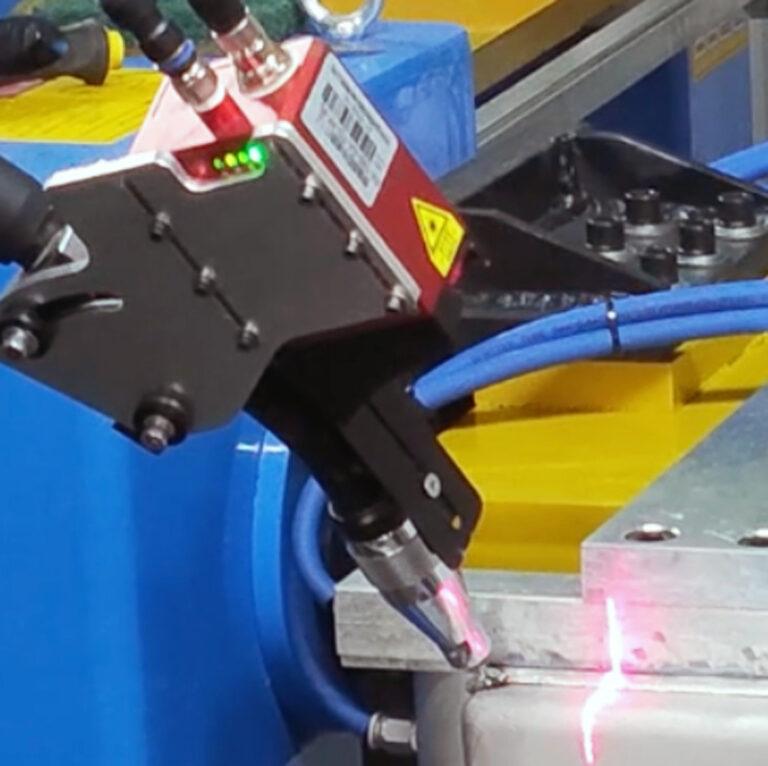

Youth utilizes a semi-automatic production line and employs bending technology instead of welding, which reduces the risk of leakage and lowers energy consumption while minimizing the number of welding seams. This production method is more environmentally friendly. All welding is completed by robots, resulting in high-quality product welding seams that are durable and long-lasting.

Different Material & Surface Treatment of Terminal HEPA Box

with Epoxy Powder

AINSI 304 or 316L

- Epoxy powder-coated steel: Epoxy powder-coated steel is durable and its surface is very wear-resistant. It is mostly used for surface treatment of outdoor curtain walls. It is very suitable for industrial purposes and environments that require frequent cleaning.

- Anodized Extruded Aluminum: Anodized aluminum is lightweight and highly corrosion-resistant, making it ideal for complex structures and environmentally friendly.

- Stainless Steel AINSI 304 or 316L: 304 stainless steel is versatile and widely used due to its corrosion resistance, while 316L stainless steel is preferred in harsher environments due to its higher resistance to chloride corrosion, but costs more than epoxy Powder coated steel as well as extruded aluminum.

- Thermoformed ABS: Lightweight and durable, this strong and versatile plastic is suitable for a wide range of applications from automotive parts to medical equipment, but is temperature sensitive and not suitable for use in high-temperature environments.

Powder Coating Finishing of HEPA Filter Box:

with Epoxy Powder

- Ensure the application of a consistent and compact coating on the steel plate surface to enhance its corrosion resistance and extend its lifespan.

- Opt for coatings with high hardness and excellent resistance to wear, enabling effective protection against physical and chemical damage.

- Offer a variety of coating colors and textures to meet customer preferences, concealing any imperfections or unevenness on the iron plate surface and delivering a clean and uniform aesthetic.

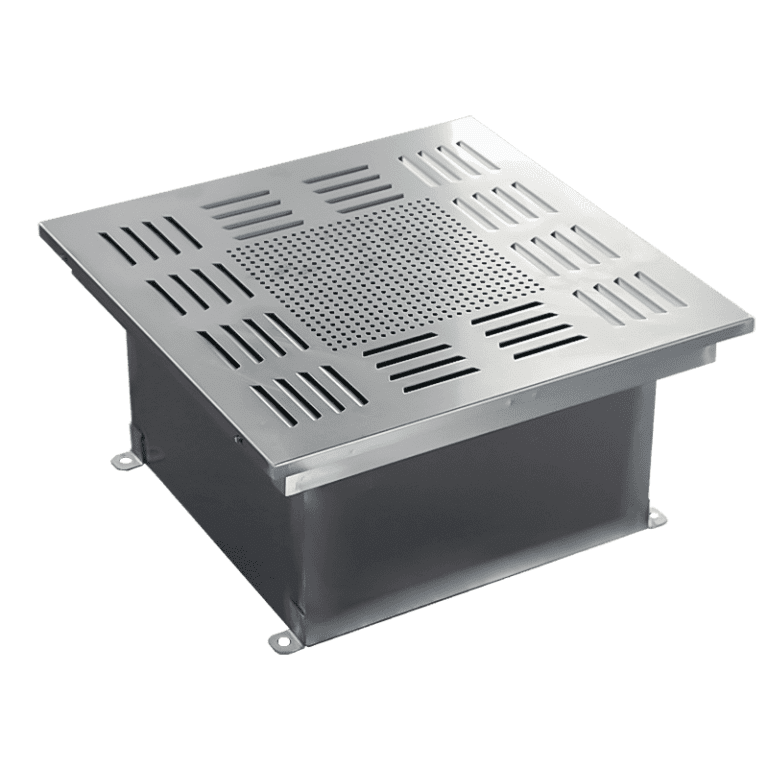

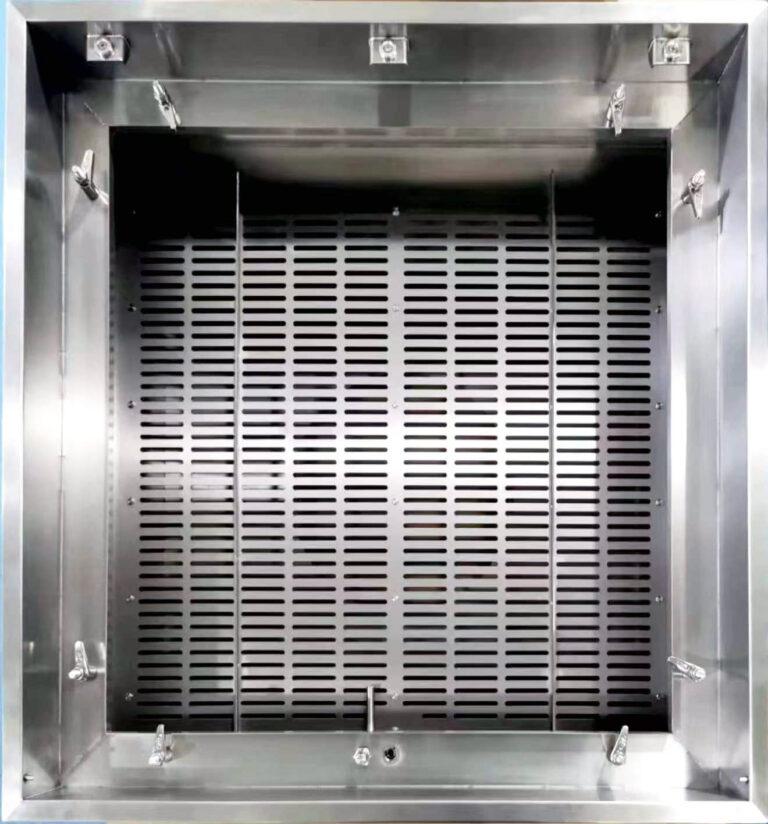

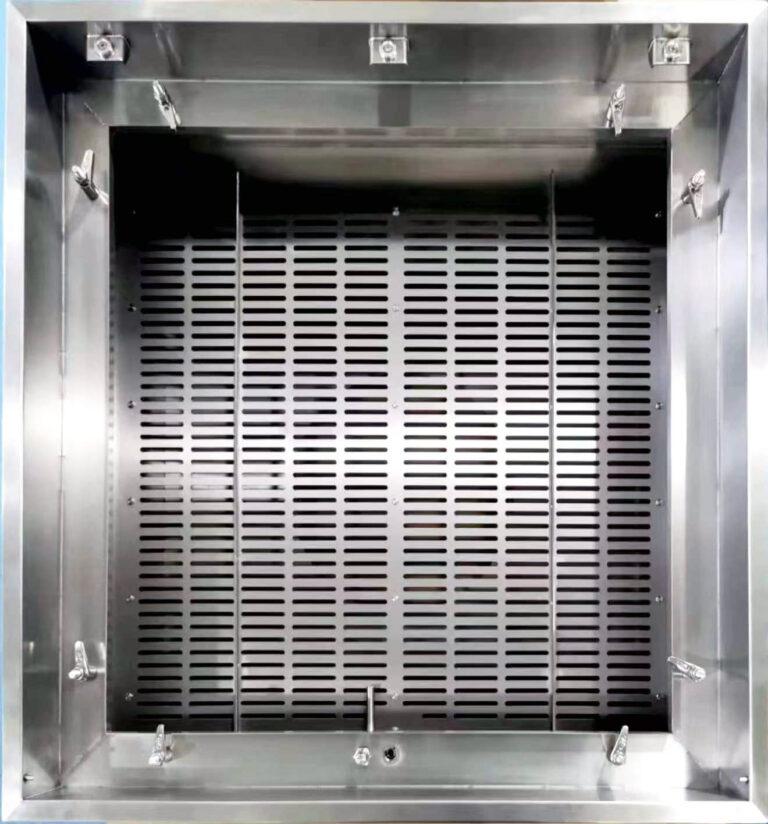

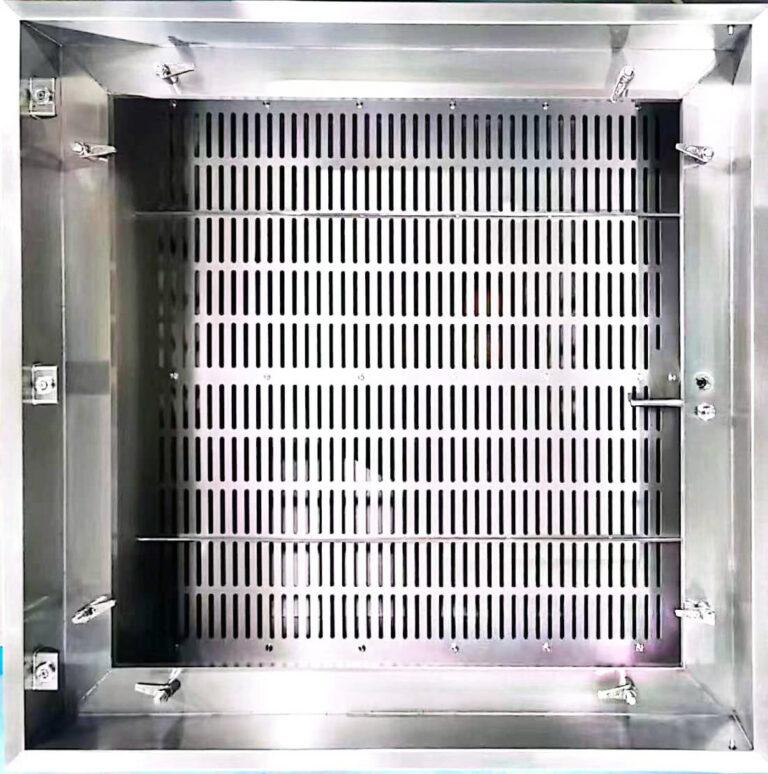

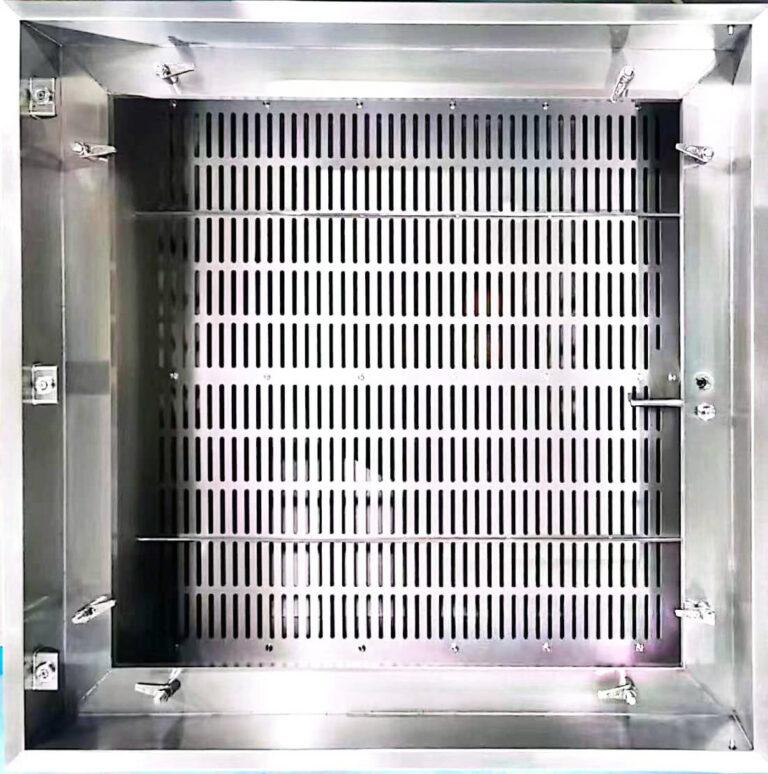

Stainless Steel HEPA Box Features:

AINSI 304 or 316L

- Brushed grinding enhances the visual appeal and texture of stainless steel, resulting in increased gloss. Additionally, the treated surface is easier to clean. In case of scratches or wear, simple grinding can restore the stainless steel surface, reducing maintenance costs and efforts.

- Micro-arc treatment on the four corners reduces sharp edges, promoting safety and minimizing the risk of accidental injuries.

- Electrolytic treatment can be applied to enhance the corrosion resistance of stainless steel, preventing the formation of oxide layers.

- Stainless steel inherently possesses remarkable durability and oxidation resistance. By employing appropriate surface treatments, the service life of stainless steel can be further extended.

Different Frame

of HEPA Box

of HEPA Box

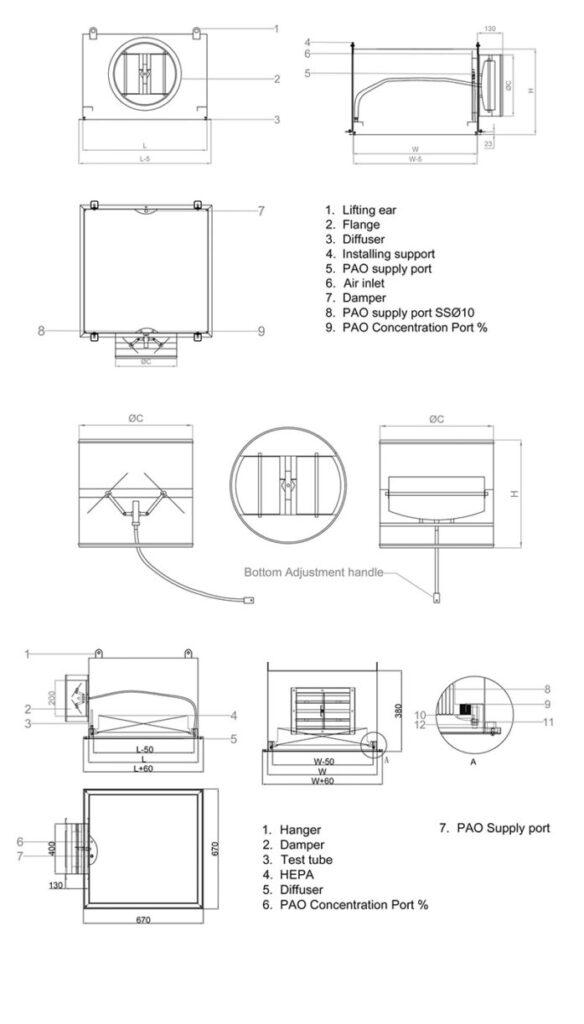

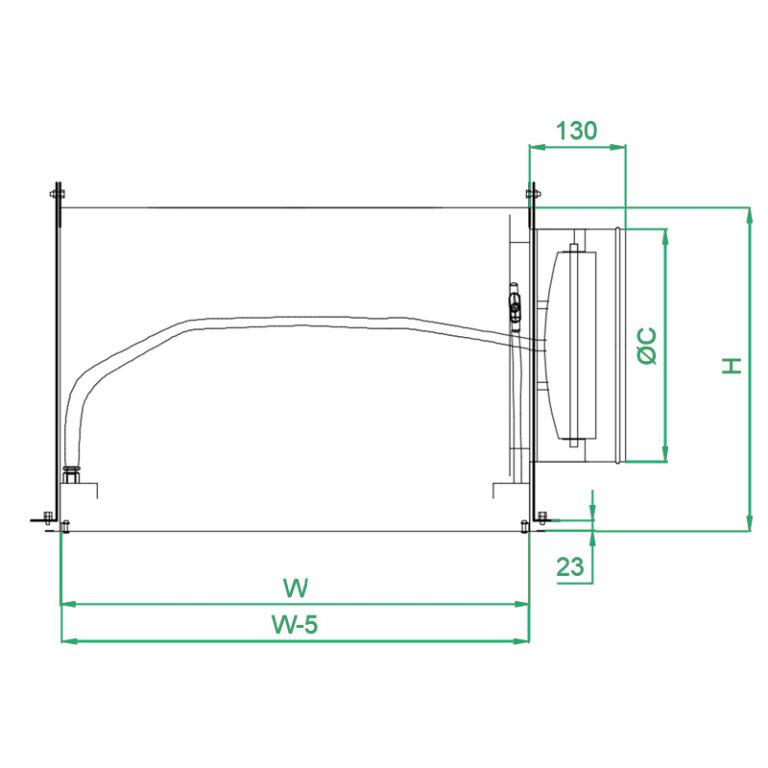

Different Installation Methods (Air Duct Connection Method)

of HEPA Box

of HEPA Box

Different Terminal Diffuser Types of HEPA Housing Box

Different Installation Methods for HEPA Housing Box Terminal Diffuser

- Covering method: This installation method neatly wraps the HEPA filter housing by covering the surface with a larger area than the box. It is easy to disassemble and assemble, but if the method is used improperly, there is a risk of deformation.

- Side Screw Mounting Method: The side screw mounting method is a sturdy and simple method that uses screws on the side of the housing to hold the diffuser in place. This method is accurate and reliable, but there are many steps for disassembly and assembly, and it is necessary to reserve screw disassembly and assembly positions during installation.

- Recessed Flush Method: For a seamless and clean look, the recessed flush method allows the diffuser face to be flush with the ceiling or wall. This is a very beautiful installation method, which requires higher manufacturing technology and is easy to disassemble and assemble.

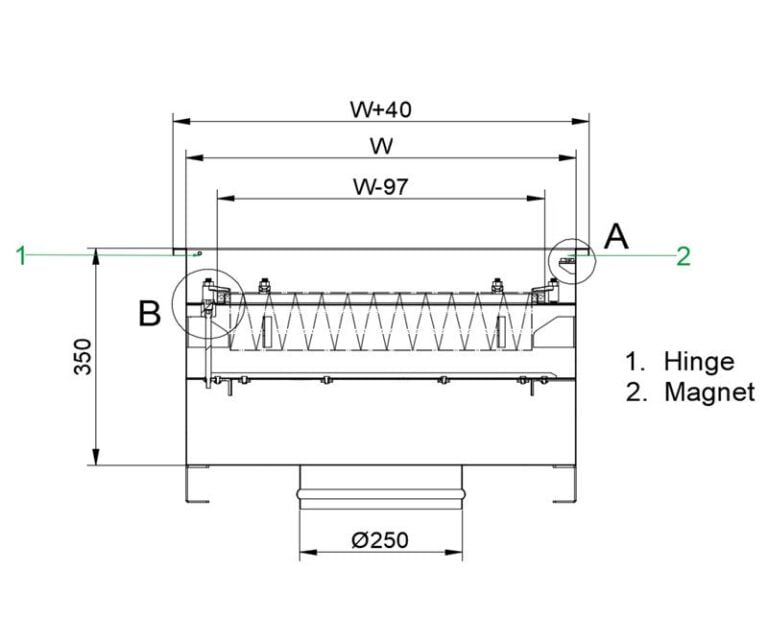

- Magnetic screw-free installation: Magnetic screw-free installation has a stylish, modern appearance and allows tool-free installation. Magnets are used to hold the diffuser in place, allowing it to be quickly installed or removed for maintenance without the need for screws, ensuring a beautiful appearance and easy disassembly and assembly while avoiding the risk of contamination from using additional tools.

- Spring Clamp Method: This method uses spring clamps to secure the diffuser to the housing box. This is a safe and often faster installation process, and can be easily removed for filter replacement or cleaning without the need for additional tools.

Different HEPA/ULPA Filter Types of HEPA Filter Box

Different Damper Types of HEPA Housing Box

of HEPA Housing Box

YOUTH's Integrated Gear Box Design of HEPA Housing Box Damper

of HEPA Housing Box

Return and adjustment damper

- Duckbill-style

- Actuator lever

- Worm gearing

Location for adjusting damper

- In the interstitial space

- Inside the room

YOUTH's R&D Capacity

YOUTH’s Terminal HEPA Filter Housing specializes in designing cutting-edge cleanroom equipment tailored to your specific requirements. Our experienced team of engineers and designers collaborates with you to create customized solutions that meet the highest industry standards. With our expertise, advanced technology, and comprehensive range of equipment, Youth’s Design Service ensures optimal performance and efficiency for your cleanroom operations. Contact us today to discuss your cleanroom equipment design needs and experience the difference of Youth’s innovative solutions.

Model | HEPA Size (mm) | Box Size (mm) | Flange Size of Duct (mm) | Height of Box (mm) | Hole size (mm) |

HB 500 | 410×410×93 | 460×460×250 | 200×200 | 500 | 470×470 |

HB 1000 | 550×550×93 | 600×600×250 | 320×200 | 1000 | 610×610 |

HB 1500 | 650×650×93 | 700×700×250 | 320×250 | 1500 | 710×710 |

FAQs

- Can HEPA Housing Boxes be repaired or do they need to be replaced if damaged?

No, once the HEPA Box casing is damaged, it must be replaced. All YOUTH’s HEPA Box shells are fully welded to ensure that all air passes through the filter in the correct path. Moreover, the special surface treatment ensures that no new contaminant particles will enter the controlled environment. - Are there different types of HEPA filters that can fit in a HEPA Housing Box?

Yes, HEPA Housing Boxes can accommodate various HEPA filter types, including those with different efficiencies, such as HEPA/ULPA (H13 or H14), depending upon the requirement of the application. - How do you test a HEPA Housing Box to ensure it is working properly?

In YOUTH, We do the 100% test of our HEPA Housing Box. Testing is typically done through methods such as a particle count test or a DOP/PAO test to ensure the filter’s integrity and performance. - What is the pressure drop across a typical HEPA filter in a Housing Box?The pressure drop across a typical HEPA filter in a Housing Box generally ranges from 2.0 to 2.5 inches of water gauge (500 to 620 Pa) at the rated airflow. However, this can vary based on the filter’s design and the airflow rate. It’s crucial to consider this in system design to maintain proper airflow as the filter becomes loaded with particulates over time.

- What certifications should a HEPA Housing Box meet?

A HEPA Housing Box should meet certifications and standards such as:

1. ISO 14644-1: Cleanroom air cleanliness classification.

2. EN 1822: Performance testing for HEPA and ULPA filters in Europe.

3. IEST-RP-CC034: Testing procedures for HEPA and ULPA filter installations.

4. EU GMP: Guidelines for pharmaceutical and biotech product manufacturing in cleanrooms.

These ensure that the HEPA Housing Box is compliant with industry requirements for air purity and filtration efficiency.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- The Ultimate Guide to YOUTH’s HEPA Housing Box: Ensuring Impeccable Cleanroom Air Quality

- What is a HEPA Housing Box and Why is it Essential for Cleanrooms?

- Understanding YOUTH HEPA Housing Boxes for Cleanroom Environments

- HEPA Housing Boxes: A Critical Component in Biotechnology Cleanrooms

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs

- Understanding the Mechanics of Fan Filter Units: A Detailed Guide

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification

- Innovative Fan Filter Units for the Next Generation of Cleanrooms