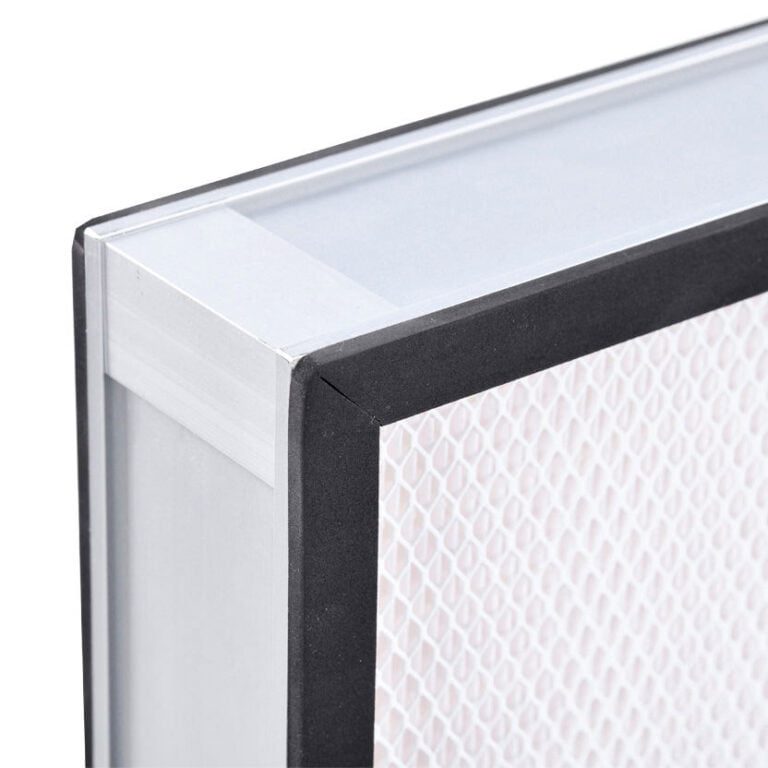

What is a Cleanroom Separator Medium-efficiency Air Filter?

Cleanroom Separator Medium-efficiency Air Filters are designed to remove particulate matter from the air while maintaining a low-pressure drop. These filters have a filtration efficiency of 90-95% and can remove particles as small as 1 micron. They are commonly used in cleanrooms and other critical environments that require high-quality air.

what is the Importance of Cleanroom Separator Medium-efficiency Air Filters?

Cleanroom Separator Medium-efficiency Air Filters play a critical role in maintaining a clean environment. These filters help prevent contaminants from entering cleanrooms, which can cause product defects, equipment failures, and safety hazards. Without proper air filtration, it would be impossible to maintain the level of cleanliness required in critical environments.

How Cleanroom Separator Medium-efficiency Air Filters Work?

Cleanroom Separator Medium-efficiency Air Filters work by forcing air through a filter media that traps airborne particles. These filters typically use a combination of mechanical filtration, electrostatic attraction, and diffusion to remove contaminants from the air. The media used in these filters is usually made from synthetic fibers that are pleated to increase the surface area and the filter’s efficiency.

How many Types of Cleanroom Separator Medium-efficiency Air Filters?

There are two types of Cleanroom Separator Medium-efficiency Air Filters: box filters and panel filters. Box filters are usually installed in the ceiling, while panel filters are installed in the walls. Box filters have a higher capacity and a longer life span, while panel filters are easier to install and replace.

How to Consider When Choosing Cleanroom Separator Medium-efficiency Air Filters?

When choosing Cleanroom Separator Medium-efficiency Air Filters, it’s essential to consider several factors. These include the filter’s efficiency, capacity, pressure drop, and life span. The size and type of cleanroom, the level of cleanliness required, and the airflow rate are also critical factors to consider.

What is the Maintenance and Replacement of Separator Medium-efficiency Air Filters?

Cleanroom Separator Medium-efficiency Air Filters should be replaced regularly to maintain their efficiency. The replacement frequency depends on several factors, including the type of filter, the level of contamination, and the airflow rate. It’s essential to follow the manufacturer’s recommendations for maintenance and replacement to ensure the filters perform as expected.

What is the Benefits of Using Cleanroom Separator Medium-efficiency Air Filters?

Using Cleanroom Separator Medium-efficiency Air Filters has several benefits. These filters help maintain a clean environment, prevent contamination, and improve product quality. They also help reduce equipment failures, which can save companies money in the long run. Additionally, these filters help protect workers’ health by removing harmful airborne particles, such as dust and bacteria.

What is the Applications of Cleanroom Separator Medium-efficiency Air Filters?

Cleanroom Separator Medium-efficiency Air Filters are used in various industries, including pharmaceuticals, electronics, healthcare, and food processing. These filters are essential in cleanrooms, laboratories, hospitals, and other critical environments that require high-quality air.

What is the difference with Other Types of Air Filters?

Cleanroom Separator Medium-efficiency Air Filters have several advantages over other types of air filters. Compared to High-efficiency Particulate Air (HEPA) filters, Cleanroom Separator Medium-efficiency Air Filters have a lower pressure drop, which reduces energy costs. They also have a longer life span and require less frequent replacement. Compared to Low-efficiency Air Filters, Cleanroom Separator Medium-efficiency Air Filters have a higher filtration efficiency and can remove smaller particles from the air.

| Type: | SF-M6 | SF-F7 | SF-F9 |

| Class EN779 | M6 | F7 | F9 |

| Efficiency EN779 [%] | 65 % | 85 % | 95 % |

| Initial-ΔP[Pa]at nominal airflow | 90 | 110 | 130 |

| Max. temp. [°C] | 120° | 120° | 120° |

FAQs

How often should Cleanroom Separator Medium-efficiency Air Filters be replaced?

Cleanroom Separator Medium-efficiency Air Filters should be replaced regularly, depending on several factors, including the type of filter, the level of contamination, and the airflow rate. It’s essential to follow the manufacturer’s recommendations for maintenance and replacement.

Can Cleanroom Separator Medium-efficiency Air Filters Remove harmful gases and Odors?

No, Cleanroom Separator Medium-efficiency Air Filters are designed to remove particulate matter from the air. To remove harmful gases and odors, other types of air filters, such as activated carbon filters, are required.

Are Cleanroom Separator Medium-efficiency Air Filters Expensive?

The cost of Cleanroom Separator Medium-efficiency Air Filters varies depending on several factors, including the size and type of filter, the level of efficiency required, and the manufacturer. However, these filters are generally more expensive than Low-efficiency Air Filters but less expensive than HEPA filters.

Can Cleanroom Separator Medium-efficiency Air Filters be installed in residential homes?

Cleanroom Separator Medium-efficiency Air Filters are designed for use in critical environments, such as cleanrooms, laboratories, and hospitals. While these filters can be installed in residential homes, they may not be necessary unless there are specific requirements, such as allergies or respiratory problems.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Mastering Clean Room Technology with Fan Filter Units (FFUs)

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- Navigating Biosafety Cabinet Classes: A Complete Overview

- A Comprehensive Guide to Indoor Air Quality (IAQ)

- Mastering Air Filter Selection: A Comprehensive Guide

- WHAT’S THE DIFFERENCE BETWEEN A POSITIVE AND NEGATIVE AIR PRESSURE CLEANROOM?

- Comprehensive Guide on Biological Safety Cabinets: Ensuring Laboratory Safety and Integrity

- Installation, Operation, and Maintenance of Cleanroom Equipment: A Comprehensive Guide