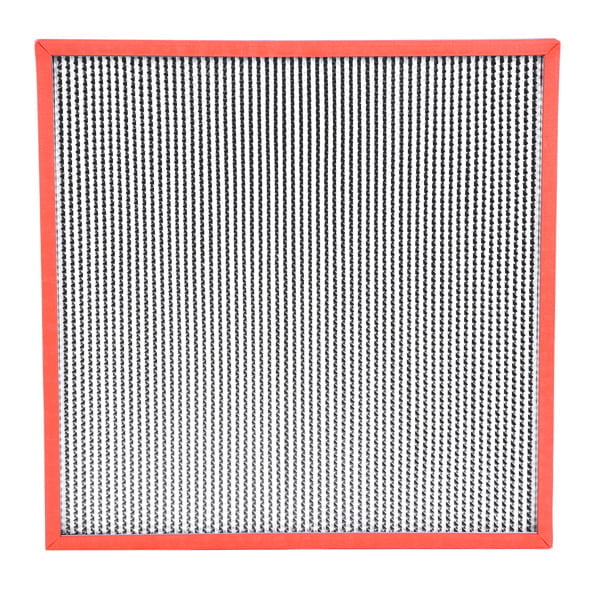

What is Cleanroom High-Temperature HEPA Air Filter?

Cleanroom High-Temperature HEPA air filter is a type of air filter designed to remove particles as small as 0.3 microns from the air. The filter is specifically designed to withstand high temperatures and is made from materials that can withstand high temperatures without losing their efficiency. The Cleanroom High-Temperature HEPA air filter is used in industries where high-temperature operations are necessary, such as the pharmaceutical, food processing, medical, and semiconductor industries.

| Model (E=efficiency) | Width | Height | Depth | Nominal airflow [m3/h] |

| SF610610150-E (E11-H14) | 610 | 610 | 150 | 1200 |

| SF762610150-E (E11-H14) | 762 | 610 | 150 | 1500 |

| SF820610150-E (E11-H14) | 820 | 610 | 150 | 1600 |

| SF320320220-E (E11-H14) | 320 | 320 | 220 | 400 |

| SF484484220-E (E11-H14) | 484 | 484 | 220 | 1000 |

| SF630630220-E (E11-H14) | 630 | 630 | 220 | 1600 |

| SF1260630220-E (E11-H14) | 1260 | 630 | 220 | 3200 |

| SF592592292-E (E11-H14) | 592 | 592 | 292 | 2000 |

| SF610610292-E (E11-H14) | 610 | 610 | 292 | 2100 |

How does a High-Temperature HEPA air filter work?

Cleanroom High-Temperature HEPA air filter is a type of air filter designed to remove particles as small as 0.3 microns from the air. The filter is specifically designed to withstand high temperatures and is made from materials that can withstand high temperatures without losing their efficiency. The Cleanroom High-Temperature HEPA air filter is used in industries where high-temperature operations are necessary, such as the pharmaceutical, food processing, medical, and semiconductor industries.

How does High-Temperature HEPA air filter work?

The Cleanroom High-Temperature HEPA air filter works by using the HEPA filtration process. The air is drawn into the filter, and the particles are trapped within the filter’s fibers. The filter is made up of multiple layers of fibers that are arranged in a random pattern. This pattern allows the filter to capture a broad range of particles of different sizes. The Cleanroom High-Temperature HEPA air filter has a high filtration efficiency of up to 99.97%.

| Type: | SF-E11 | SF-H13 | SF-H14 |

| Class EN1822 | E11 | H13 | H14 |

| Efficiency EN1822@ MPPS [%] | 95% | 99.95% | 99.995% |

| Initial-ΔP[Pa]at nominal airflow | 125 | 250 | 260 |

| Max. temp. [°C] | 120°/opt.280° | 120°/opt.280° | 120°/opt.280° |

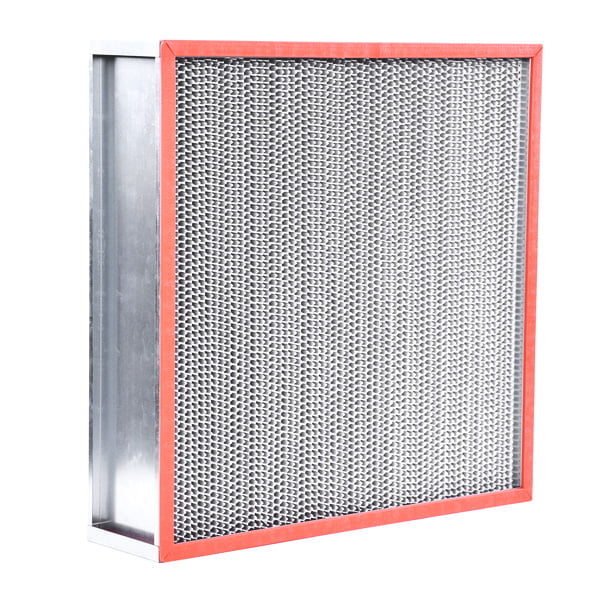

The high temperature HEPA/ULPA air filter can achieve a filtration efficiency of ≥99.99% for 0.3μm particles at a temperature of 350°C, and an efficiency of ≥99.95% for MPPS. The air filter can operate at a high airflow rate of 1,440m3/h in a 150mm depth implementation and 2,100m3/h in a 290mm depth implementation. Youth’s unique design enables rapid temperature control, which can significantly reduce heating times. The high durability of the overall structure of the air filter effectively controls the risk of downtime during production, while the low operating resistance of ≤250 Pa reduces energy costs.

What are the Benefits of High-Temperature HEPA air filters?

- Improved air quality: The Cleanroom High-Temperature HEPA air filter ensures that the air quality in the cleanroom is of the highest standard. The filter removes particles that could potentially contaminate the environment, making it suitable for sensitive manufacturing processes.

- Reduced contamination risk: The filter reduces the risk of contamination in the cleanroom, thereby ensuring the safety of the products produced in the cleanroom.

- Increased efficiency: The Cleanroom High-Temperature HEPA air filter improves the efficiency of the cleanroom by reducing the need for frequent cleanups and maintenance. This, in turn, leads to increased productivity and reduced costs.

Applications of Cleanroom High-Temperature HEPA air filter

The Cleanroom High-Temperature HEPA air filter finds applications in various industries, including:

- Pharmaceutical industry: Cleanroom High-Temperature HEPA air filter is used in the manufacturing of pharmaceutical products to ensure a contamination-free environment.

- Food processing industry: The filter is used in the food processing industry to prevent contamination of food products during the manufacturing process.

- Medical industry: The Cleanroom High-Temperature HEPA air filter is used in medical facilities to provide a clean environment for patients and prevent the spread of infectious diseases.

- Semiconductor industry: The filter is used in the semiconductor industry to prevent contamination of microchips during the manufacturing process.

How to Maintenance of High-Temperature HEPA air filter?

The Cleanroom High-Temperature HEPA air filter requires regular maintenance to ensure its efficiency. The filter should be cleaned and replaced periodically to prevent clogging and maintain air quality. It is also essential to inspect and test the filter regularly to ensure it meets the required standards.

Frame: Stainless Steel

Header: Box type, Single/Double-Header.

Media: High temperature resistant glass fiber.

Efficiency:

H11 (EN 1822) / MERV 16 (ASHRAE 52.2)

MPPS:≥95% / DOP: ≥99.9%@0.3 µm

H13 (EN 1822) / MERV 17-18 (ASHRAE 52.2)

MPPS: ≥99.95% / DOP: ≥99.99%@0.3 µm

H14 (EN 1822) / MERV 19 (ASHRAE 52.2)

MPPS:≥99.995% / DOP: ≥99.999%@0.3 µm

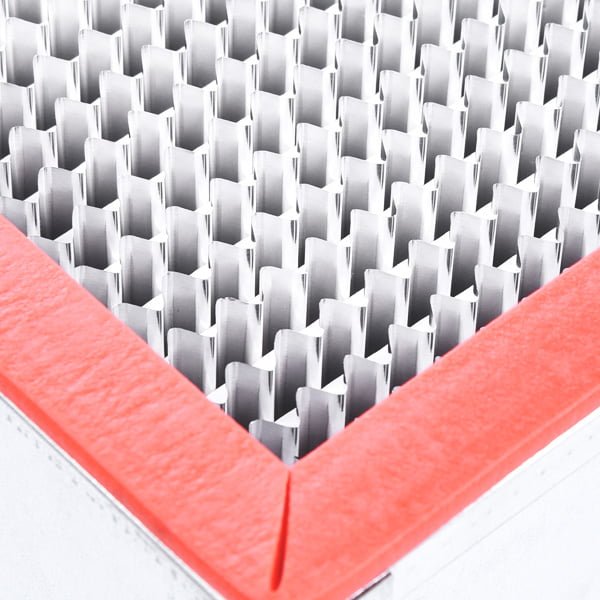

Separator: Aluminum foil

Sealant: Ceramic glues

Max. Temperature:≦ 350°C

Max. Humidity:≦ 100% RH

Available for being applied in the pharmaceutical industry and hospitals.

- Control airflow under high humidity

- Hammed edges eliminate possible pleat damage

- Extend life span with low initial resistance

FAQs

What is the difference between HEPA and ULPA filters?

HEPA and ULPA filters both remove particles from the air, but ULPA filters have a higher efficiency of up to 99.9995% compared to HEPA filters’ efficiency of up to 99.97%.

Can Cleanroom High-Temperature HEPA air filters be reused?

No, the Cleanroom High-Temperature HEPA air filter cannot be reused as the filter’s efficiency decreases with each use.

How often should a High-Temperature HEPA air filter be replaced?

Cleanroom High-Temperature HEPA air filters should be replaced periodically, depending on the environment’s level of contamination and the manufacturer’s recommendations.

What is the lifespan of a Cleanroom High-Temperature HEPA air filter?

The lifespan of a Cleanroom High-Temperature HEPA air filter depends on several factors, including the environment’s level of contamination and the manufacturer’s specifications.

What are the certifications required for a Cleanroom High-Temperature HEPA air filter?

Cleanroom High-Temperature HEPA air filters should have certifications from regulatory bodies such as ISO, FDA, and CE to ensure that they meet the required standards.

Youth 10,000-level clean workshop

Youth special structure design

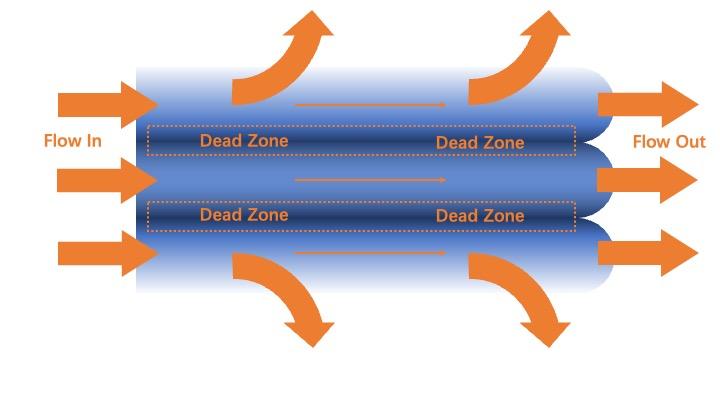

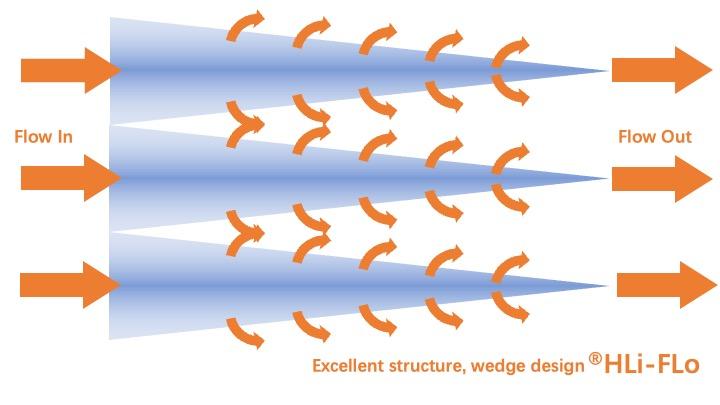

The HEPA air filter designed and produced by Youth Company is a groundbreaking innovation in air filtration technology. Unlike traditional stacked filters, our filter utilizes a unique wedge-shaped structure called the HLi-FLo design, which optimizes the core filtering material for maximum effectiveness.

Our scientific and superior design results in better performance, lower pressure drop, and reduced energy consumption. By utilizing the filter material more efficiently, we can extend the filter’s lifespan and lower the total cost of ownership for our customers. Our product is more efficient and user-friendly, providing a cost-effective solution to clean air.

YOUTH Q&C

HEPA filter material

HEPA filter material

- MPPS inspection

- 100% smoke inspection

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- Mastering Clean Room Technology with Fan Filter Units (FFUs)

- How to Control Clean Room Temperature: A Comprehensive Guide

- Fan Filter Units: Balancing Efficiency and Cost-Effectiveness

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification

- Exploring the Versatility of Fan Filter Units Across Different Sectors

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Achieving Precision and Cleanliness: The Power of Fan Filter Units