What is a Gel-Seal HEPA/ULPA Air Filter?

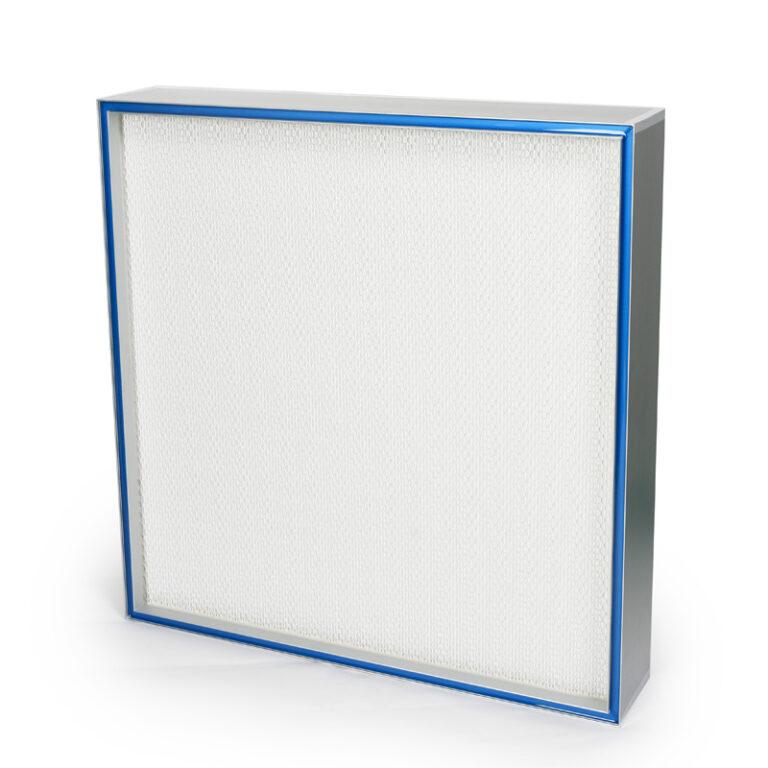

Ge-Seal HEPA/ULPA filters are a type of HEPA/ULPA filter that has been designed to provide maximum efficiency and safety in cleanroom environments. They are manufactured using a unique glass fiber material that provides superior filtration and dust-holding capacity.

The Gel-Seal HEPA/ULPA air filter uses a gel sealant to create a tight seal between the filter and the filter housing. This sealant ensures that there are no leaks or gaps, which can allow contaminants to enter the cleanroom.

These filters are designed to seal perfectly, ensuring that no air leaks occur, which can lead to contamination risks.

How many Types of the Gel-Seal?

Side Gel

Top Gel

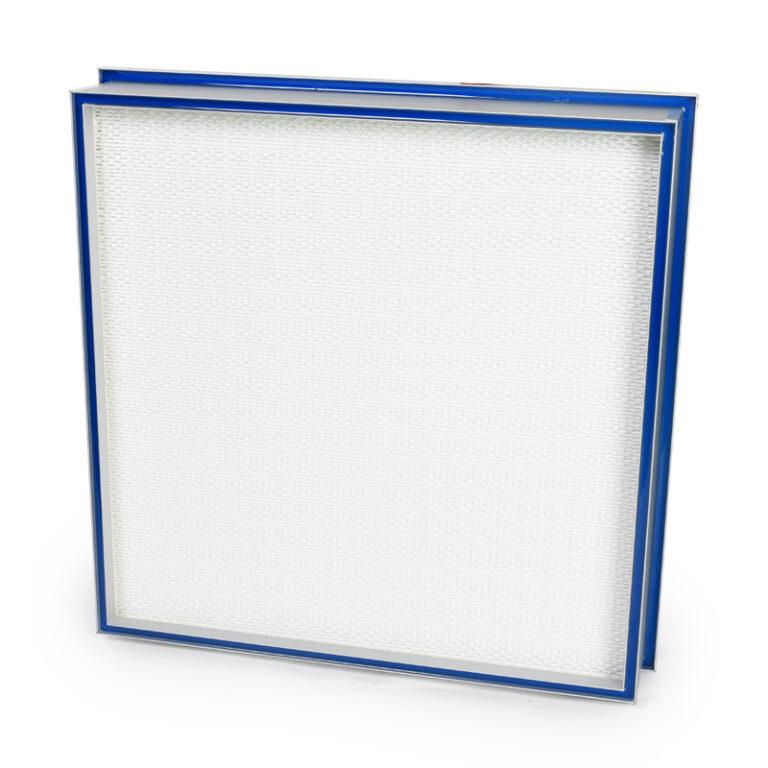

Double Gel

Side Gel + PU Seal

Benefits of Gel-Seal HEPA/ULPA Air Filters

The use of Ge-Seal HEPA filters offers several benefits to cleanroom environments, including enhanced air quality, improved cleanroom efficiency, and reduced contamination risks. The filters can effectively remove 99.97% of particles as small as 0.3 microns, ensuring that the air in the cleanroom is free from dust, bacteria, and other harmful contaminants. This not only protects the products being manufactured but also ensures the safety of workers in the cleanroom.

The benefits of using Gel-Seal HEPA/ULPA air filters in cleanrooms, including:

- High Efficiency – Gel-Seal HEPA/ULPA air filters have a high-efficiency rate of 99.99% at 0.3 microns. This means that they can remove particles and contaminants as small as 0.3 microns from the air. This high-efficiency rate ensures that the cleanroom remains free of contaminants.

- Gel Sealant – The gel sealant used in Gel-Seal HEPA/ULPA air filters ensures that there are no leaks or gaps. This sealant creates a tight seal between the filter and the filter housing, ensuring that contaminants cannot enter the cleanroom.

- Long Lifespan – Gel-Seal HEPA/ULPA air filters have a long lifespan compared to other types of filters. They can last up to two years before needing to be replaced. This reduces the cost of maintenance and ensures that the cleanroom remains clean and free of contaminants.

- Energy Efficiency – Gel-Seal HEPA/ULPA air filters are energy-efficient. They use less energy than other types of filters, which reduces the overall cost of operating the cleanroom.

YOUTH Customized Service

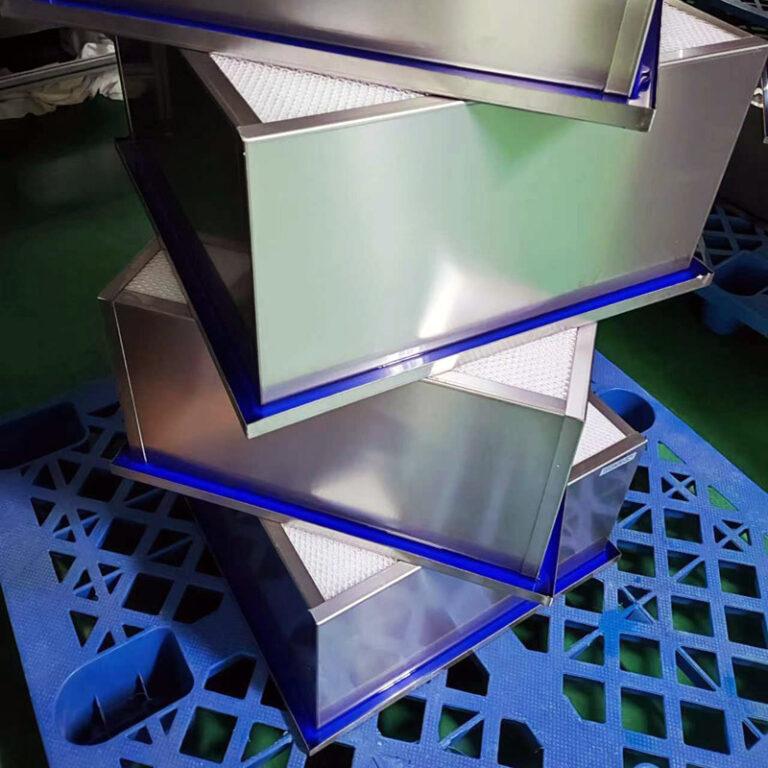

According to the different requirements of customers, an aluminum frame or stainless steel frame can be selected, and the customized height is from 70 to 292mm, which provides a larger filtration area.

The standard size of 610×610×292 can achieve an air volume of more than 3200CMH. Its structure and material selection have been optimized to reduce the resistance of air passing through the filter while maintaining high-efficiency filtration.

The use of SS304 material makes it ideal for harsh environments. It has excellent mechanical strength and durability, ensuring long-term stable performance, rust, and corrosion resistance, and ensuring the reliability and durability of the filter.

What are the applications of Ge-Seal HEPA Filters?

Ge-Seal HEPA filters are used in a variety of industries, including pharmaceuticals, biotechnology, microelectronics, and healthcare. In the pharmaceutical industry, they are used in the manufacturing of drugs and vaccines, while in the biotechnology industry, they are used in research laboratories. In the microelectronics industry, they are used in the manufacturing of computer chips, while in the healthcare industry they are used in hospital operating rooms, laboratories, and isolation rooms.

How to maintenance and Replacement of Ge-Seal HEPA Filters?

Proper maintenance and replacement of Ge-Seal HEPA filters are crucial to ensure their effectiveness in cleanroom environments. Regular maintenance, including cleaning and checking for leaks, is necessary to ensure the filters are working optimally. The filters should also be replaced periodically, depending on the level of usage and the manufacturer’s recommendations. It is essential to follow the proper guidelines for replacement to avoid contamination risks.

How Gel-Seal HEPA/ULPA Air Filters Work?

Gel-Seal HEPA/ULPA air filters work by trapping particles and contaminants in the filter media. The filter media is made up of a fine mesh of fibers that capture particles and contaminants as they pass through. The gel sealant used in the filter creates a tight seal between the filter and the filter housing, ensuring that there are no leaks or gaps.

Quality Standards and Certifications for Ge-Seal HEPA Filters

Ge-Seal HEPA filters are manufactured to meet specific quality standards and certifications to ensure their effectiveness in cleanroom environments. These standards include ISO and EN standards. These certifications ensure that the filters meet specific requirements for efficiency, leakage, and durability. It is essential to choose Ge-Seal HEPA filters that have these certifications to ensure they meet the necessary standards.

Cost-Benefit Analysis of Ge-Seal HEPA Filters

Investing in Ge-Seal HEPA filters may seem like a significant initial cost. However, it is crucial to consider the long-term benefits, such as improved air quality, increased cleanroom efficiency, and reduced contamination risks. This can lead to significant cost savings in the long run, especially when considering the costs of product recalls due to contamination and increased labor costs due to low efficiency.

Common Misconceptions about Ge-Seal HEPA Filters

There are several common misconceptions about Ge-Seal HEPA filters, such as that they are expensive, difficult to maintain, and do not last long. These misconceptions are false, and it is essential to understand the facts before making any decisions about investing in these filters.

Future of Ge-Seal HEPA Filters

With advancements in technology, the future of Ge-Seal HEPA filters looks promising. There are continuous efforts to improve their efficiency, durability, and ease of use. As the demand for cleanrooms continues to grow, the need for effective air filtration systems like Ge-Seal HEPA filters will continue to increase.

FAQs

What is the difference between HEPA filters and ULPA filters?

HEPA filters can remove particles as small as 0.3 microns, while ULPA filters can remove particles as small as 0.12 microns.

What is the shelf life of Ge-Seal HEPA filters?

The shelf life of Ge-Seal HEPA filters can vary depending on the manufacturer and usage. It is essential to follow the manufacturer’s recommendations for proper storage and use.

How do Youth Ge-Seal HEPA filters compare to other brands in the market?

Youth Ge-Seal HEPA filters are a popular choice in the market due to their unique features, such as their glass fiber material and perfect sealing design. However, it is essential to compare different brands based on quality standards, certifications, and cost-benefit analysis before making any decisions.

How often should I replace Gel-Seal HEPA/ULPA air filters in my cleanroom?

Gel-Seal HEPA/ULPA air filters can last up to two years before needing to be replaced. However, it is essential to check the air filter regularly and replace it if it is dirty or has reached the end of its lifespan.

Can I install Gel-Seal HEPA/ULPA air filters myself?

It is recommended to have a professional install Gel-Seal HEPA/ULPA air filters to ensure that they are installed correctly and create a tight seal.

Are Gel-Seal HEPA/ULPA air filters more expensive than other types of air filters?

Gel-Seal HEPA/ULPA air filters may be more expensive initially than other types of filters. However, their long lifespan and energy efficiency make them more cost-effective in the long run.

How do Gel-Seal HEPA/ULPA air filters compare to other types of air filters?

Gel-Seal HEPA/ULPA air filters have a higher efficiency rate and a longer lifespan than other types of filters. They are also energy-efficient, making them a popular choice for cleanrooms.

Can Gel-Seal HEPA/ULPA air filters be used in other applications besides cleanrooms?

Gel-Seal HEPA/ULPA air filters are designed specifically for cleanroom applications. However, they may be used in other applications that require high-efficiency air filtration.

Applications of Gel-Seal HEPA/ULPA Air Filters

Gel-Seal HEPA/ULPA air filters are used in a variety of industries and applications, including:

- Pharmaceutical Industry – In the pharmaceutical industry, Gel-Seal HEPA/ULPA air filters are used in cleanrooms to ensure that the environment remains sterile. They are used in manufacturing, packaging, and research and development.

- Electronics Industry – In the electronics industry, Gel-Seal HEPA/ULPA air filters are used in cleanrooms to remove particles and contaminants from the air. They are used in the manufacturing of computer chips, semiconductors, and other electronic components.

- Healthcare Industry – In the healthcare industry, Gel-Seal HEPA/ULPA air filters are used in cleanrooms to ensure that the environment remains clean and free of contaminants. They are used in hospitals, laboratories, and other healthcare facilities.

How to Install Gel-Seal HEPA/ULPA Air Filters?

Installing Gel-Seal HEPA/ULPA air filters is a straightforward process. Here are the steps to follow:

- Turn off the cleanroom’s HVAC system.

- Remove the existing air filter from the filter housing.

- Clean the filter housing to ensure that there is no dirt or debris.

- Remove the protective cover from the new Gel-Seal HEPA/ULPA air filter.

- Place the new filter into the filter housing, making sure that it is securely in place.

- Apply the gel sealant around the edges of the filter to create a tight seal.

- Turn on the cleanroom’s HVAC system and check that the air filter is working correctly.

Maintenance of Gel-Seal HEPA/ULPA Air Filters

Maintaining Gel-Seal HEPA/ULPA air filters is essential to ensure that they continue to work correctly. Here are some maintenance tips:

- Check the air filter regularly to ensure that it is clean and free of contaminants.

- Replace the air filter when it is dirty or has reached the end of its lifespan.

- Clean the filter housing regularly to ensure that there is no dirt or debris.

- Check the gel sealant regularly to ensure that it is still creating a tight seal.

| Model (E=efficiency) | Width | Height | Depth | Nominal airflow [m³/h] |

| MP61061069-E (E11-U17) | 610 | 610 | 69 | 1000 |

| MP122061069-E (E11-U17) | 1220 | 610 | 69 | 2000 |

| MP117057070-E (E11-U17) | 1170 | 570 | 70 | 1100 |

| MP117087070-E (E11-U17) | 1170 | 870 | 70 | 1750 |

| MP1170117070-E (E11-U17) | 1170 | 1170 | 70 | 2200 |

| Model (E=efficiency) | Width | Height | Depth | Nominal airflow [m³/h] |

| MP41041093-E (E11-U17) | 410 | 410 | 93 | 500 |

| MP55055093-E (E11-U17) | 550 | 550 | 93 | 1000 |

| MP65065093-E (E11-U17) | 650 | 650 | 93 | 1500 |

| MP106055093-E (E11-U17) | 1060 | 550 | 93 | 2000 |

| MP370370104-E (E11-U17) | 370 | 370 | 104 | 500 |

| MP510510104-E (E11-U17) | 510 | 510 | 104 | 1000 |

| MP610610104-E (E11-U17) | 610 | 610 | 104 | 1500 |

| MP1020510104-E (E11-U17) | 1020 | 510 | 104 | 2000 |

Youth 10,000-level clean workshop

Youth special structure design

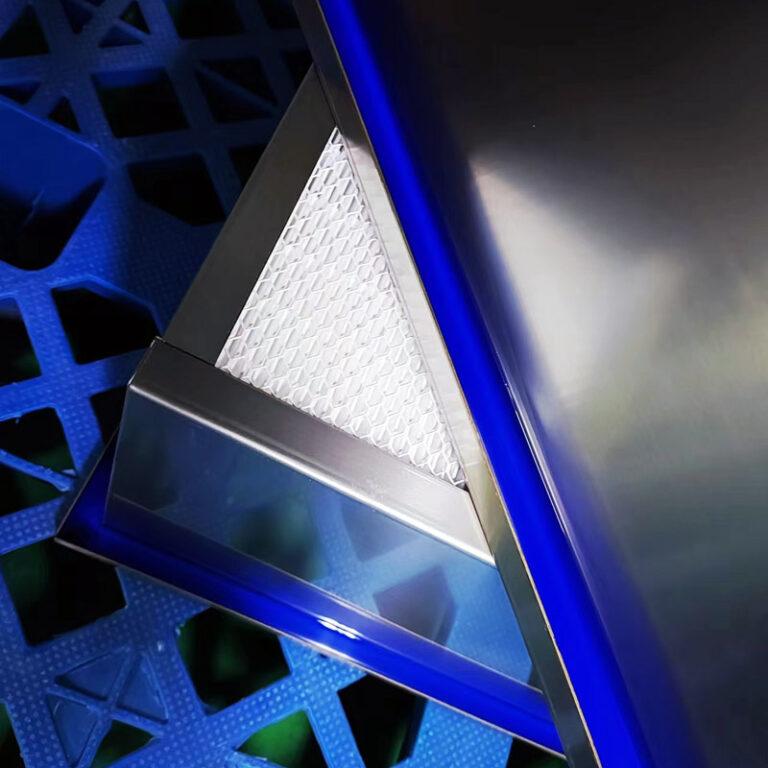

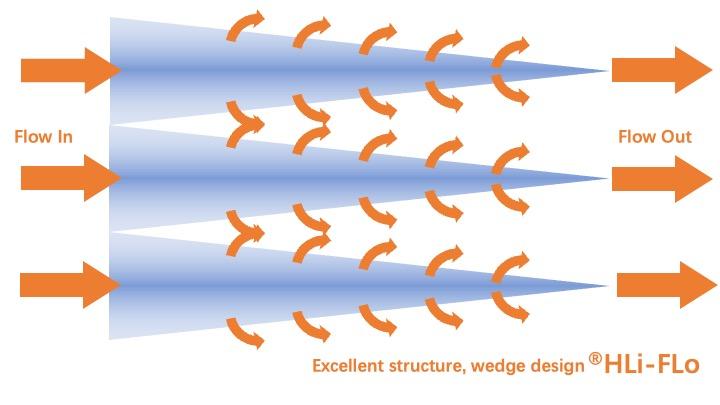

The HEPA air filter designed and produced by Youth Company is a groundbreaking innovation in air filtration technology. Unlike traditional stacked filters, our filter utilizes a unique wedge-shaped structure called the HLi-FLo design, which optimizes the core filtering material for maximum effectiveness.

Our scientific and superior design results in better performance, lower pressure drop, and reduced energy consumption. By utilizing the filter material more efficiently, we can extend the filter’s lifespan and lower the total cost of ownership for our customers. Our product is more efficient and user-friendly, providing a cost-effective solution to clean air.

YOUTH Q&C

HEPA filter material

HEPA filter material

- MPPS inspection

- 100% smoke inspection

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- What are Gel Seal Mini-Pleat HEPA Filters and How to Make the Right Choice?

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs

- What is a HEPA Housing Box and Why is it Essential for Cleanrooms?

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Fan Filter Units: Ensuring Sterile Conditions in Cleanroom Environments

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification

- Fan Filter Units: Balancing Efficiency and Cost-Effectiveness