What is the Cleanroom Mist Shower?

The mist shower room is essential in a cleanroom as it removes contaminants from the clothing of personnel entering the room. It is versatile and equipped with exhaust vents that prevent the spread of contaminants. It complements air filtration systems, specialized clothing, and hygiene protocols to maintain regulatory cleanliness standards.

One Side

Other Side

Technical Parameter

| Single | Double |

| External dimensions: W1300 × D1200 × H2600mm | External dimensions: W1300 × D2000 × H2600mm |

| Inner dimensions: W1000 × D1000 × H2000mm | Inner dimensions: W1000 × D1800 × H2000mm |

| Water pressure requirements: 0.3MPa | Water pressure requirements: 0.3MPa |

| Air pressure requirements: 0.3MPa | Air pressure requirements: 0.3MPa |

| Spray method: ultrasonic atomization | Spray method: ultrasonic atomization |

| Control method: Siemens touch screen automatic control | Control method: Siemens touch screen automatic control |

| Power supply: 220V/50Hz | Power: 220V/50Hz |

Down

Upper

Usage Process

- Upon entering the mist shower room, press the door open button, and the door will automatically close and lock.

- The mist shower room’s atomization system operates automatically as per the predetermined time settings.

- Once the atomization cycle ends, unlock the door, remove the protective clothing, and dispose of it in the designated waste clothing collection bin.

- Exit the mist shower room, close the door, and it will lock automatically.

- After the exhaust system finishes operating according to the scheduled time, the mist shower room returns to its initial state.

Working Principle

- Working principle of the atomization system:

- The mist shower room’s atomization system starts when the atomizing fan and atomizer are turned on simultaneously.

- Air is drawn from the mist shower room’s interior through the atomization auxiliary fan, and sent through a pipeline to the atomization water tank.

- The incoming air carries the mist from the atomization water tank through the pipeline and into the mist shower room.

- Working principle of the exhaust fan:

- The exhaust fan begins operating when the mist shower room door is opened to enter.

- While the exhaust fan is operating, the spray chamber’s atomization system is closed to prevent mist from being discharged and affecting the mist shower effect.

- The exhaust fan is activated after the atomization process is complete, and it remains operational for five minutes after a person exits the mist shower room and closes the door. This creates negative pressure, discharges the indoor air, and ensures that the indoor air is free from pollution.

- door closer

- Magnetic lock

- Dust and water guns

- Stainless Steel Grille Pedals

- Stainless steel louver return air orifice

- Waterproof lamps

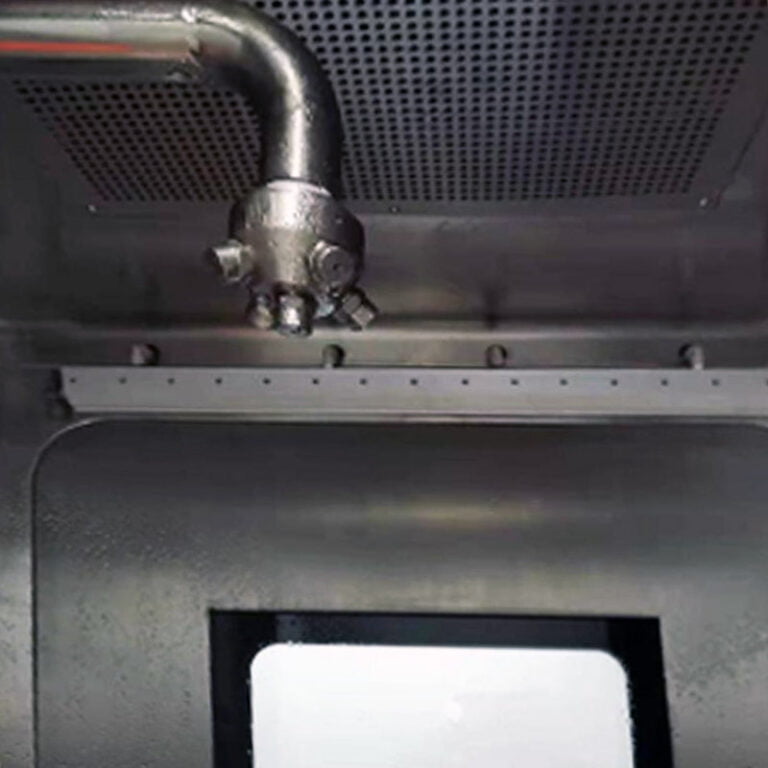

- High-pressure atomizing nozzles

- touch screen

- Pneumatic lock

- Evenly distributed high-pressure atomizing nozzles around

Product Features

- To ensure the door remains secure, staff must press the door button to enter, preventing accidental opening and closing.

- The mist shower room is equipped with a range of cleaning tools including a hand-held water gun and an air gun in addition to the atomization device, catering to different cleaning methods and making it more user-friendly.

- The ultrasonic atomization system enables delicate atomization, ensuring that the water mist is evenly sprayed on the clothes of the staff. This helps to prevent dust from being shaken off during undressing, thereby protecting the personal safety of staff.

- The comfort of personnel is significantly improved compared to traditional water pressure and water-air mixed spray, and the issue of water dripping in various areas is effectively eliminated.

- The door-type waste clothes collection bucket is designed to save space and reduce the overall size of the facility.

- The mist shower room features a hidden door frame, providing a sleek and beautiful appearance.

- The interior of the facility features slope transitions that are both aesthetically pleasing and easy to clean.

- The mist shower room utilizes a programmable PLC, which ensures that the equipment operates fully automatically and allows for adjustable timing to suit individual needs.

How to choose the cleanroom shower?

When choosing a shower for a clean room or other controlled environment, there are several factors to consider. These include the size and layout of the space, the type of contaminants that need to be removed, and the level of cleanliness required. Additionally, it is important to consider the type of shower that will be most effective and efficient for the specific application. For example, an air shower may be appropriate for removing particulate matter, while a mist shower or water shower may be better suited for removing microbial contaminants. It may also be necessary to consider the availability of utilities, such as water and electricity, and the potential impact of the shower on the overall cleanliness of the space. Ultimately, the right type of shower will depend on the specific needs and requirements of the application.

To choose the right type of shower, you should consider the specific requirements of the environment in which it will be used. For example, in a healthcare or pharmaceutical setting, a biosafety water shower with airtight doors and a built-in filtration system may be necessary to prevent the spread of contaminants. In a cleanroom, a mobile laminar airflow (LAF) unit may be more appropriate to maintain the cleanliness of the air. In either case, it is essential to consider the size of the shower, the type of filtration system, and the type of control system needed to ensure the safety and efficiency of the shower. It may also be helpful to consult with experts in the field to determine the best type of shower for your specific needs.

FAQs

A cleanroom mist shower works by releasing a fine mist of water that removes particles from the individual’s clothing and skin.

Using a cleanroom mist shower can reduce contamination levels in a cleanroom environment, improving product quality and worker safety.

Cleanroom mist showers are effective at removing particles of various sizes, including dust, hair, and skin cells.

Cleanroom mist showers are commonly used in semiconductor manufacturing, pharmaceutical manufacturing, biotechnology research, and nanotechnology research.

Yes, cleanroom mist showers can be customized to meet the specific needs of different cleanroom environments, such as the size of the room and the types of particles present.

The frequency of maintenance for a cleanroom mist shower will depend on the amount of usage and the environment in which it is being used. However, regular maintenance is essential to ensure its continued effectiveness.

Common maintenance tasks for a cleanroom mist shower include cleaning the spray nozzles, replacing the HEPA filter, and checking the pressure gauge.

Common problems that may arise with a cleanroom mist shower include clogged spray nozzles, damaged filters, and incorrect pressure levels.

Many problems with a cleanroom mist shower can be easily fixed by cleaning or replacing the affected components. However, it is important to address issues as soon as they arise to prevent contamination.

Cleanroom mist showers are generally considered to be environmentally friendly, as they use water rather than chemicals to remove particles from individuals entering or exiting a cleanroom environment.

Yes, YOUTH is committed to providing a complete set of cleanroom solutions to the world, including cleanroom mist showers that can be customized to meet the specific needs of different cleanroom environments.

Related Contents:

- Air Pressure in Biosafety Pass Box for Cleanroom

- Biosafety Passboxes: Positive vs Negative Pressure

- The Power of YOUTH Cleanroom Mist Showers: Ensuring Impeccable Cleanliness

- Biosafety Airtight Doors: Essential Components for Contamination Control

- Cleanroom Mist Showers: A Comprehensive Guide to YOUTH’s Advanced Decontamination Solutions

- Advanced Features of YOUTH Cleanroom Water Showers

- Unlocking the Power of Hydrogen Water Generators

- Customizing Biosafety Airtight Doors for Optimal Protection

- Biosafety Airtight Doors: Mastering Air Pressure Control