What is the Biosafety Cabinet for Cleanroom?

A cleanroom biological safety cabinet is a specialized workspace used in environments where it is important to maintain a high level of cleanliness and prevent contamination. It is typically found in a laboratory or medical facility and is used for tasks such as handling and processing biological materials, such as drugs or other chemicals. A cleanroom biological safety cabinet is a self-contained workspace that is designed to be free of contaminants and is typically equipped with a ventilation system to help keep the air clean. In addition, the cabinet may have features such as a clean operation bench and a fume hood to help prevent the release of potentially hazardous materials. The biological safety cabinet is also designed to provide a barrier between the user and the materials being handled, helping to prevent exposure to biological hazards.

How Many Types of Cleanroom Biosafety Cabinets?

There are three main types of cleanroom biosafety cabinets: Class I, Class II, and Class III.

Class I cabinets are the most basic and are primarily used for personnel protection. They have an open front, with a HEPA filter located at the back of the cabinet. The air inside the cabinet is constantly being filtered, ensuring that the operator is protected from any airborne hazards.

Class II cabinets provide personnel and product protection. They are designed to filter the air inside the cabinet and exhaust it back into the room. The exhaust air is passed through a HEPA filter to ensure that it is free from contaminants. Class II cabinets are further divided into four types: A1, A2, B1, and B2.

Class III cabinets provide the highest level of containment. They are designed for working with highly hazardous biological agents and toxins. Class III cabinets are completely enclosed, with access provided through tightly sealed gloves attached to the cabinet.

Design and Construction of Cleanroom Biosafety Cabinets

Cleanroom biosafety cabinets are constructed using materials that are resistant to chemical and biological agents. The most common materials used include stainless steel and powder-coated steel. HEPA filters are used to filter the air inside the cabinet, removing airborne contaminants.

The airflow design of the cabinet is critical to its effectiveness. The airflow is designed to move from the cleanest area (the HEPA filter) to the least clean area (the work surface). This ensures that any contaminants produced during the work process are contained within the cabinet.

Ergonomics is also an important consideration when designing a cleanroom biosafety cabinet. The work surface should be designed to minimize operator fatigue and discomfort during extended work periods.

Maintenance of Cleanroom Biosafety Cabinets

To ensure that cleanroom biosafety cabinets function effectively, regular maintenance is required. This includes regular cleaning of the cabinet, filter replacement, and performance testing.

Regular cleaning of the cabinet is necessary to remove any residual contaminants that may have accumulated on the surface. Filter replacement is also essential to ensure that the cabinet continues to function effectively.

Performance testing is carried out to ensure that the cabinet is operating within the required specifications. This involves testing the airflow velocity, filter integrity, and particle count within the cabinet.

Applications of Cleanroom Biosafety Cabinets

Cleanroom biosafety cabinets have a wide range of applications in various industries. In the medical industry, they are used in the handling of infectious agents, as well as in the preparation of sterile products. In research laboratories, cleanroom biosafety cabinets are used in the handling of biological agents, as well as in cell culture work. In the pharmaceutical industry, they are used in the production of drugs and vaccines.

Advantages of Cleanroom Biosafety Cabinets

Cleanroom biosafety cabinets provide several advantages. They ensure that the operator is protected from airborne hazards and prevent the spread of contaminants. They also improve the efficiency of work processes by providing a controlled environment that minimizes the risk of errors and contamination.

70% recycled and 30% discharged

B2 is 100% discharged

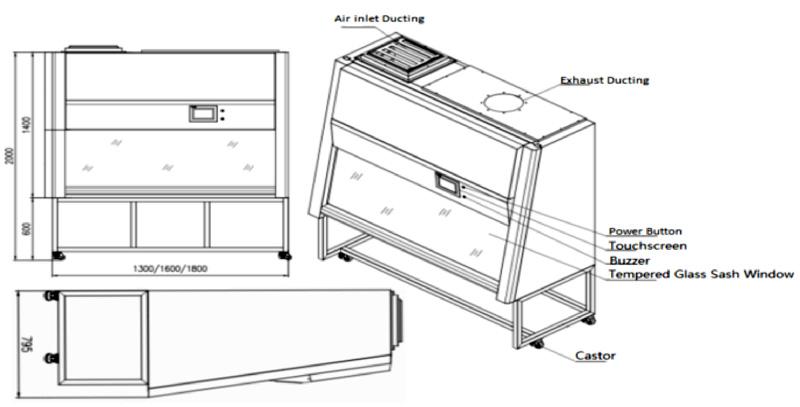

Youth Biosafety Cabinet Feature:

At YOUTH, we understand the importance of safety when it comes to handling biological materials. That’s why we offer a range of biological safety cabinets (BSCs) that are designed to provide a barrier between the user and the materials being handled, helping to prevent exposure to biological hazards.

Our BSCs are box-shaped, negative-pressure air purification safety equipment that can prevent potentially harmful biological particles from evaporating during experimental operations. They are typically found in laboratories or medical facilities and are used for tasks such as handling and processing biological materials, including drugs or other chemicals.

We offer cleanroom biological safety cabinets that are self-contained workspaces designed to be free of contaminants. They are typically equipped with a ventilation system to help keep the air clean and may have features such as a clean operation bench and a fume hood to prevent the release of potentially hazardous materials.

Our BSCs also come with sterilizing systems with safety interlocks, making them ideal for use in microbiology, biomedicine, genetic engineering, and the manufacturing of biological products. We offer a Class II A2 Vertical laminar negative pressure model where 70% of the airflow is filtered and recycled, and 30% of the airflow can be discharged into the room or connected to the exhaust system after being filtered. We also offer a Class II B2 Vertical laminar negative pressure model where 100% of the airflow can be discharged into the room or connected to the exhaust system after being filtered.

Our BSCs feature a large LCD screen for real-time running status monitoring, password management that can be set to avoid misuse, and displays showing how long the filter will last as well as how long the fan and UV light will operate. Each biological safety cabinet is factory tested for product performance and safety, and meets international standards.

At YOUTH, we are committed to providing high-quality biological safety cabinets that help protect users from potential biological hazards.

FAQs:

What is a Cleanroom Biosafety Cabinet?

A Cleanroom Biosafety Cabinet is an enclosed workspace designed to provide a controlled environment that prevents the spread of contaminants and protects the operator from airborne hazards.

What are the different types of Cleanroom Biosafety Cabinets?

There are three types of Cleanroom Biosafety Cabinets: Class I, Class II, and Class III. Each type offers varying levels of protection and features.

What is the difference between a Class I and Class II Cleanroom Biosafety Cabinet?

The main difference between Class I and Class II Cleanroom Biosafety Cabinets is that Class II cabinets have HEPA-filtered exhaust air, which protects the environment outside the cabinet.

What is the function of a HEPA filter in a Cleanroom Biosafety Cabinet?

HEPA filters in a Cleanroom Biosafety Cabinet are used to remove airborne particles, including bacteria and viruses, from the air circulating within the cabinet.

What is the difference between a Cleanroom Biosafety Cabinet and a fume hood?

While both Cleanroom Biosafety Cabinets and fume hoods provide a controlled environment, Cleanroom Biosafety Cabinets are designed to protect the operator from airborne hazards, while fume hoods are designed to protect the operator from chemical hazards.

What is the minimum air exchange rate required for a Cleanroom Biosafety Cabinet?

The minimum air exchange rate required for a Cleanroom Biosafety Cabinet is 12 air changes per hour, which ensures that the air in the cabinet is replaced at least 12 times per hour.

What is the purpose of a UV light in a Cleanroom Biosafety Cabinet?

UV lights in a Cleanroom Biosafety Cabinet are used to sterilize the work area before and after use, ensuring that no contaminants remain.

What should be done if a Cleanroom Biosafety Cabinet is not functioning properly?

If a Cleanroom Biosafety Cabinet is not functioning properly, it should be immediately taken out of service and serviced by a qualified technician.

How often should Cleanroom Biosafety Cabinets be serviced?

Cleanroom Biosafety Cabinets should be serviced at least once a year, but more frequent servicing may be required depending on usage and environmental conditions.

What is the maximum noise level of a Cleanroom Biosafety Cabinet?

The maximum noise level of a Cleanroom Biosafety Cabinet is 65 decibels, which is equivalent to the noise level of a normal conversation.

What is the maximum operating temperature of a Cleanroom Biosafety Cabinet?

The maximum operating temperature of a Cleanroom Biosafety Cabinet is typically around 25°C, as higher temperatures can affect the performance of HEPA filters.

Can Cleanroom Biosafety Cabinets be customized to fit specific needs?

Yes, Cleanroom Biosafety Cabinets can be customized to fit specific needs, including size, features, and functionality. YOUTH provides complete cleanroom solutions tailored to the specific needs of customers.

Related Contents:

- Navigating Biosafety Cabinet Classes: A Complete Overview

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Comprehensive Guide to Biosafety Cabinets: Safeguarding Research and Laboratories

- Comprehensive Guide on Biological Safety Cabinets: Ensuring Laboratory Safety and Integrity

- Ensuring Biohazard Safety: Best Practices for Biological Safety Cabinet Use

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Fan Filter Units: Ensuring Sterile Conditions in Cleanroom Environments

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification