What is a Cleanroom Separator Type HEPA Air Filter?

A cleanroom separator type HEPA air filter is a high-efficiency particulate air filter that is designed to remove 99.97% of airborne particles as small as 0.3 microns. The filter is constructed using a dense mat of randomly arranged fibers that trap and hold particles as they pass through the filter. The filter is installed in the air handling unit or cleanroom ceiling and works by forcing the air through the filter media, trapping and removing any particles present in the air.

How Does a Cleanroom Separator Type HEPA Air Filter Work?

Cleanroom separator type HEPA air filters work based on the principle of diffusion, interception, and impaction. Diffusion occurs when particles are small enough to move randomly through the air, colliding with air molecules and eventually being trapped by the filter media. Interception occurs when particles larger than the gaps in the filter media get trapped by the fibers as they try to pass through the filter. Impaction occurs when larger particles move in a straight line and collide with the fibers, getting trapped and removed from the air.

What is the Benefits of a Cleanroom Separator Type HEPA Air Filter?

There are several benefits of using a cleanroom separator-type HEPA air filter in a cleanroom environment. The first and most important benefit is that it helps maintain the desired air quality levels in the cleanroom by removing 99.97% of airborne particles. This ensures the safety of personnel and products in the cleanroom. Secondly, the filter is designed to allow the system to control laminar air flow under high humidity, which helps maintain a stable environment in the cleanroom. Thirdly, the hemmed edges on the aluminum reduce possible pleat damage, extending the life of the filter. Lastly, the filters meet UL900 fire resistance, ensuring safety in the event of a fire.

What are the Applications of Separator Type HEPA Air Filters?

Cleanroom separator-type HEPA air filters are used in a variety of industries, including pharmaceuticals, electronics, and healthcare. They are essential components of cleanrooms that require high levels of air quality, such as semiconductor manufacturing, research labs, and hospitals. Cleanroom separator-type HEPA air filters are also used in biological safety cabinets, fume hoods, and laminar flow hoods.

How to Consider When Choosing a Cleanroom Separator Type HEPA Air Filter?

- There are several factors to consider when choosing a cleanroom separator type HEPA air filter.

- The first factor is the efficiency of the filter.

- Choosing a filter with a high-efficiency rating is essential to ensure the removal of the smallest particles.

- The second factor is the pressure drop across the filter. A filter with a high-pressure drop will reduce the airflow and increase energy consumption. It is important to choose a filter with a low-pressure drop to ensure optimal airflow and energy efficiency.

- The third factor is the size of the filter. The filter must be the correct size to fit the air handling unit or cleanroom ceiling.

- The fourth factor is the filter frame. The filter frame must be constructed of durable material that can withstand the conditions of the cleanroom environment.

- The fifth factor is the maintenance requirements of the filter. It is important to choose a filter that is easy to maintain and replace to ensure optimal performance.

How to Maintenance and Replacement of a Cleanroom Separator Type HEPA Air Filter?

Maintenance and replacement of a cleanroom separator-type HEPA air filter are essential to ensure optimal performance. The filter must be inspected regularly to ensure that it is clean and free of damage. If the filter is dirty or damaged, it must be replaced immediately to maintain the desired air quality levels in the cleanroom. The frequency of filter replacement depends on several factors, including the size of the filter, the efficiency of the filter, and the number of contaminants present in the cleanroom environment. It is recommended to follow the manufacturer’s instructions for filter maintenance and replacement.

| Type: | SF-E11 | SF-H13 | SF-H14 |

| Class EN1822 | E11 | H13 | H14 |

| Efficiency EN1822@ MPPS [%] | 95% | 99.95% | 99.995% |

| Initial-ΔP[Pa]at nominal airflow | 125 | 250 | 260 |

| Max. temp. [°C] | 120°/opt.280° | 120°/opt.280° | 120°/opt.280° |

| Model (E=efficiency) | Width | Height | Depth | Nominal airflow [m3/h] |

| SF610610150-E (E11-H14) | 610 | 610 | 150 | 1200 |

| SF762610150-E (E11-H14) | 762 | 610 | 150 | 1500 |

| SF820610150-E (E11-H14) | 820 | 610 | 150 | 1600 |

| SF320320220-E (E11-H14) | 320 | 320 | 220 | 400 |

| SF484484220-E (E11-H14) | 484 | 484 | 220 | 1000 |

| SF630630220-E (E11-H14) | 630 | 630 | 220 | 1600 |

| SF1260630220-E (E11-H14) | 1260 | 630 | 220 | 3200 |

| SF592592292-E (E11-H14) | 592 | 592 | 292 | 2000 |

| SF610610292-E (E11-H14) | 610 | 610 | 292 | 2100 |

FAQs

What is a cleanroom separator type HEPA air filter?

A cleanroom separator-type HEPA air filter is a high-efficiency particulate air filter that is designed to remove 99.97% of airborne particles as small as 0.3 microns.

What are the benefits of using a cleanroom separator-type HEPA air filter?

The benefits of using a cleanroom separator-type HEPA air filter include maintaining a stable environment in the cleanroom, extending the life of the filter, and ensuring safety in the event of a fire.

What industries use cleanroom separator-type HEPA air filters?

Cleanroom separator-type HEPA air filters are used in industries such as pharmaceuticals, electronics, and healthcare.

What factors should be considered when choosing a cleanroom separator type HEPA air filter?

Factors to consider when choosing a cleanroom separator type HEPA air filter include efficiency, pressure drop, size, frame, and maintenance requirements.

How often should a cleanroom separator-type HEPA air filter be replaced?

The frequency of filter replacement depends on several factors, including the size of the filter, the efficiency of the filter, and the amount of contaminants present in the cleanroom environment. It is recommended to follow the manufacturer’s instructions for filter maintenance and replacement.

Youth 10,000-level clean workshop

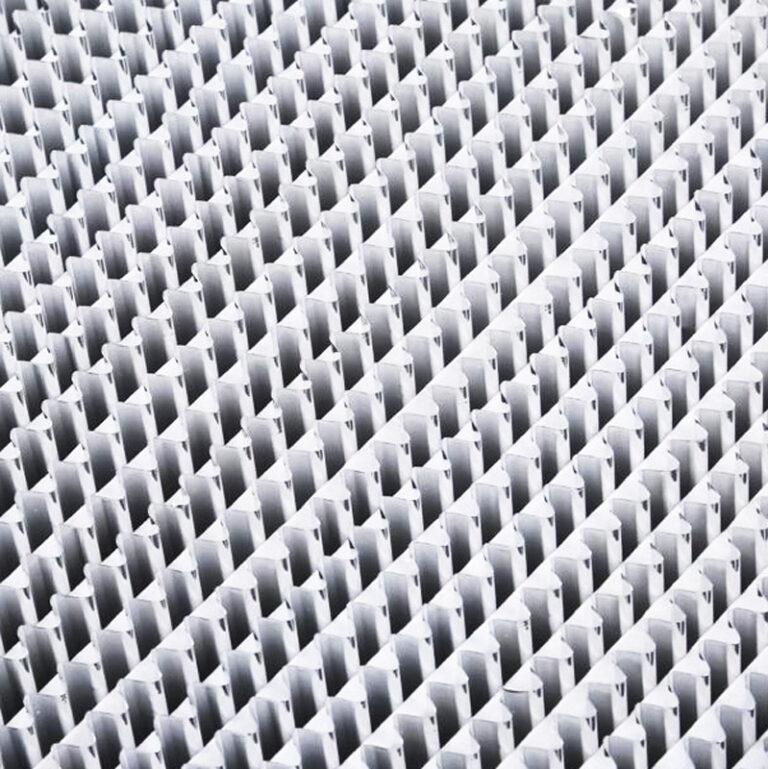

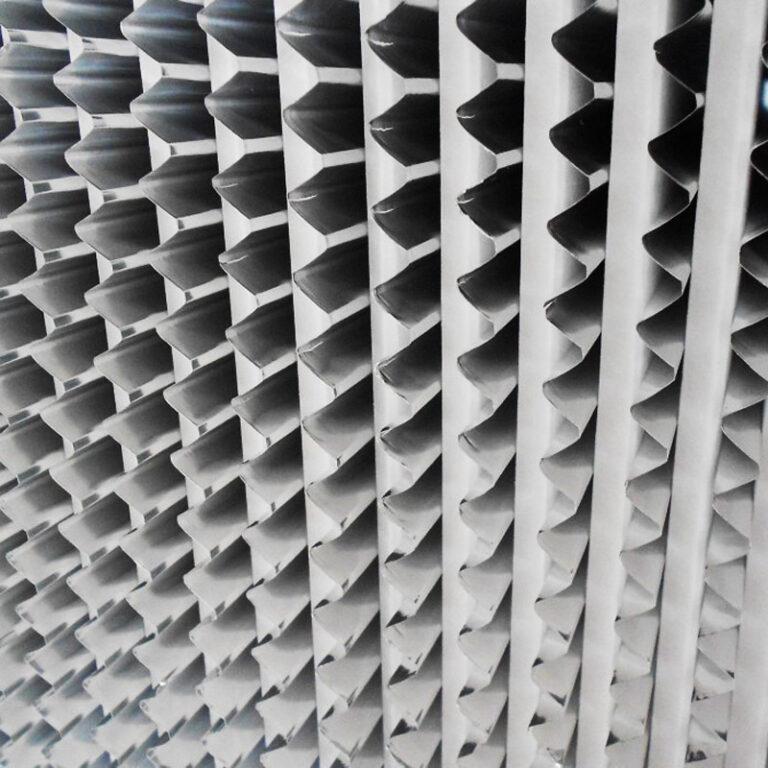

Youth special structure design

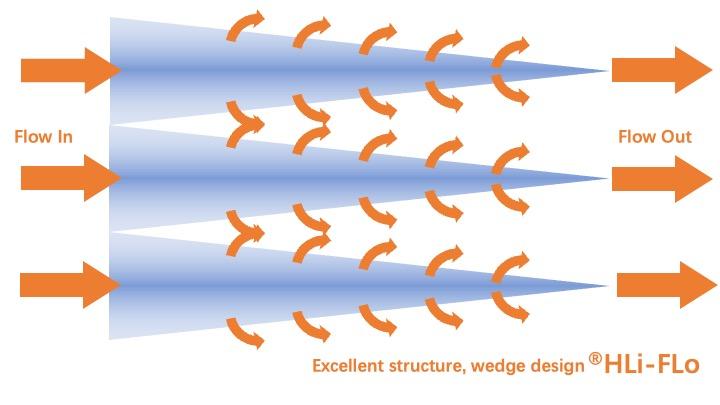

The HEPA air filter designed and produced by Youth Company is a groundbreaking innovation in air filtration technology. Unlike traditional stacked filters, our filter utilizes a unique wedge-shaped structure called the HLi-FLo design, which optimizes the core filtering material for maximum effectiveness.

Our scientific and superior design results in better performance, lower pressure drop, and reduced energy consumption. By utilizing the filter material more efficiently, we can extend the filter’s lifespan and lower the total cost of ownership for our customers. Our product is more efficient and user-friendly, providing a cost-effective solution to clean air.

YOUTH Q&C

HEPA filter material

HEPA filter material

- MPPS inspection

- 100% smoke inspection

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- Mastering Clean Room Technology with Fan Filter Units (FFUs)

- The Comprehensive Guide to Bag-in-Bag-Out (BIBO) HEPA Filter Replacement

- Navigating Biosafety Cabinet Classes: A Complete Overview

- Fan Filter Units: Balancing Efficiency and Cost-Effectiveness

- A Comprehensive Guide to Indoor Air Quality (IAQ)

- How to Replace Aerospace Cleanroom Filters for Optimal Air Quality

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs