What is the Dunk tank for Cleanroom?

The dunk tank was used to transfer goods to different sides of a cleanroom or biology laboratory. is a special pass box that uses liquid disinfection to achieve sterilization purposes.

It serves as a piece of equipment for the secure transfer of items, maintaining a sterile environment throughout the process. While standard pass-through boxes are engineered to fulfill basic cleanliness standards, high-level biosafety pass-through boxes are designed for use in advanced biosafety labs (BSL-3, BSL-4, ABSL-3, ABSL-4) and in spaces where air tightness is critical.

YOUTH's Features

The Youth’s cleanroom biosafety dunk tank is designed for use in biosafety laboratories. It is composed of an immersion tank box, cover plate, clapboard, drain valve, internal transmission system, control system, signal output, alarm system, and disinfection and liquid drain. The inner groove of the tank is made of 316L stainless steel, while the outer layer is made of 304 stainless steel, providing high/low-temperature resistance, corrosion resistance, waterproofing, and impact resistance.

The tank has a fully welded inner cavity and double airtight doors with an interlocking structure. It also has disinfectant emptying and safety overflow and water sealing devices. The airtightness of the tank is ensured through mechanically compressed airtight covers on both sides. The tank is equipped with an electric closed valve and automatic water supply, as well as a water level display and alarm. It also has a standard fumigation and disinfection interface.

The control system of the immersion tank uses PLC programmable control, allowing for automatic control of the tank. The control system can also be linked to a central control system for real-time monitoring and control. The tank is used to immerse and disinfect positive pressure protective clothing and other equipment in a biosafety laboratory, effectively removing dangerous pathogenic microorganisms and ensuring the safety and cleanliness of the surrounding environment. The tank is equipped with an emergency stop button and an alarm system to ensure the safety of personnel during use. The cleanliness level of the inner cavity of the tank meets the requirements of biosafety laboratories, with a cleanliness level of Class 100-100,000.

Product Features

- The buried depth of the liquid level of the baffle is not less than 10cm;

- With low liquid level sound and light alarm function;

- Using manual delivery of items, with built-in cover plates and hooks to ensure that the items can be fully immersed in the liquid and avoid contact with disinfectant by the operator’s limbs as much as possible. There are control boards on both sides of the box, which can be operated on both sides

- Goods are conveyed to the bottom of the cabinet for forced disinfection, and the length of disinfection can be set;

- Mechanical compression-type airtight doors are installed on both sides of the dunk tank;

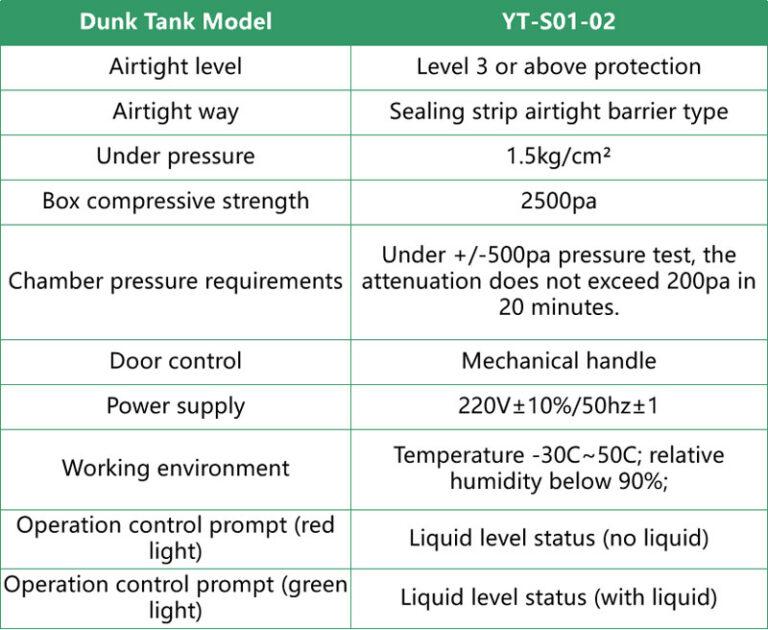

- When the sealing performance of the cabinet meets the pressure of 1000 Pa, the hourly leak rate is not more than 0.25%. Bearing capacity shall be no less than 2000Pa;

- The installation height of the dunk tank is subject to the actual measurement at the project site, which is conducive to the discharge of disinfectant.

Specification and Advantages

- The system adopts PLC and can be customized according to customer requirements.

- Designed with an airtight structure, it can be used for rooms with air-tightness requirements;

- It is equipped with a low liquid level alarm function for disinfectant, which is safe.

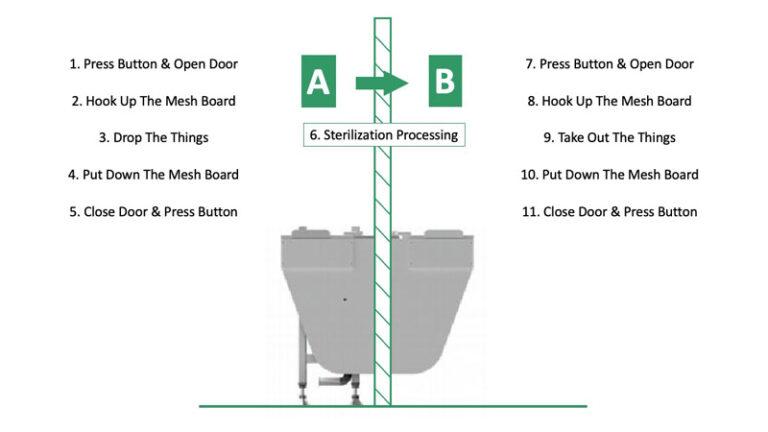

Operation Process

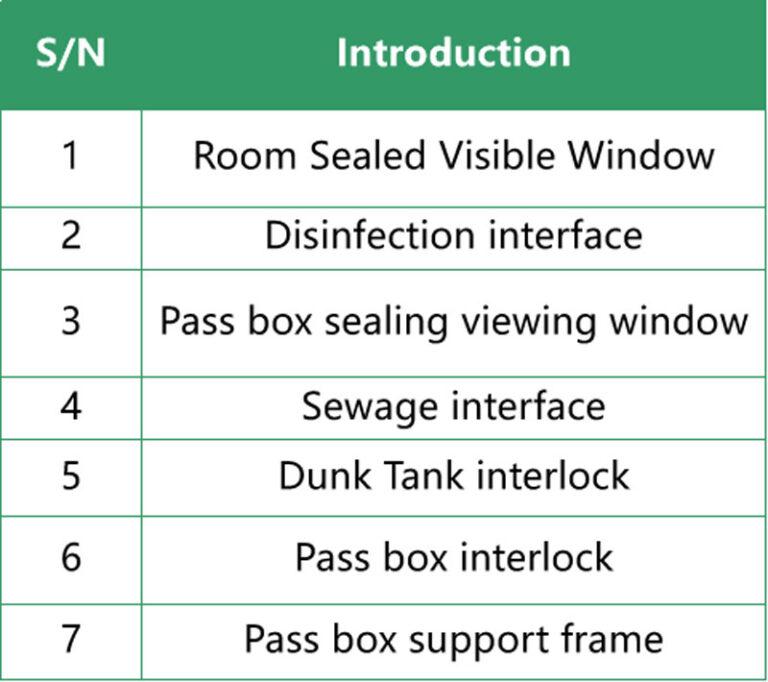

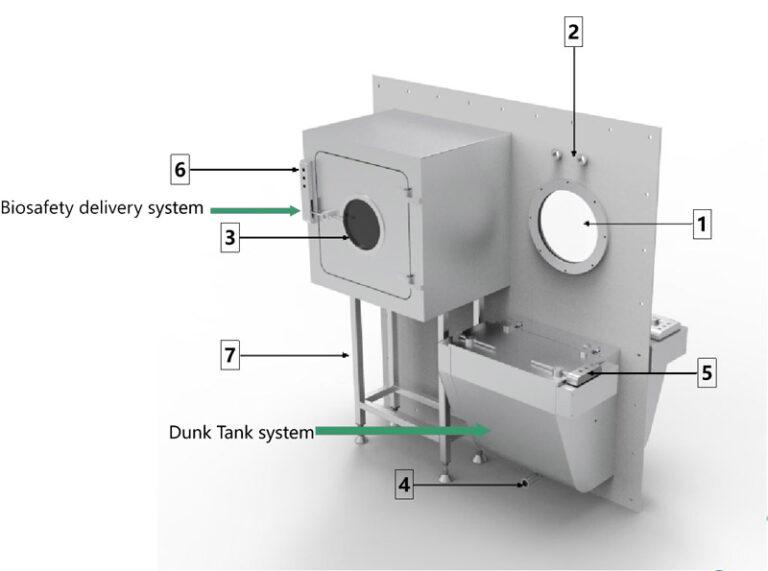

Integrated System of Biosafety Pass Box and Dunk Tank

Integration Benefits of Biosafety Pass Box and Dunk Tank

- Compact Design Concept, Saving On-site Operating Environment

- Solving Different Workflow Processes in the Same Area

- Interlock Function, Compliant with GMP Standards

- Higher Level of Air Tightness Protection

- Providing Professional Technical Installation Solutions

What is the cleanroom biosafety dunk tank used for?

Biosafety dunk tanks are commonly used in pharmaceutical manufacturing or biotechnology, where it is critical to maintain a high level of cleanliness and control over the environment to prevent contamination of products or processes.

In a cleanroom, a biosafety dunk tank is used to decontaminate materials and equipment that have been used in the cleanroom or that have come into contact with potentially contaminated materials. This helps to prevent contamination of the cleanroom and ensure that the products or processes being carried out within the cleanroom remain pure and uncontaminated.

Biosafety dunk tanks are also used to decontaminate materials and equipment when they are being transported out of the cleanroom. This helps to prevent contaminants from being carried out of the cleanroom and potentially contaminating other areas.

How to choose cleanroom biosafety dunk tank for your cleanroom projects?

There are a few factors to consider when choosing a cleanroom biosafety dunk tank for your cleanroom projects:

- Size: Make sure the biosafety dunk tank is large enough to accommodate the materials or equipment you will be decontaminating.

- Material: Biosafety dunk tanks are typically made of stainless steel or other corrosion-resistant materials. Choose a material that is suitable for the specific requirements of your cleanroom.

- Capacity: Consider the volume of the dunk tank and the amount of materials or equipment you need to decontaminate. Make sure the dunk tank has sufficient capacity to handle your needs.

- Disinfectant: Choose a disinfectant that is suitable for your needs and compatible with the materials and equipment you will be decontaminating.

- Certification: Make sure the biosafety dunk tank you choose is certified for use in cleanrooms or controlled environments. This ensures that it meets the necessary standards for cleanliness and contamination control.

It’s also a good idea to work with a supplier who has experience in providing cleanroom biosafety dunk tanks and can help you choose the right product for your needs.

Related Contents:

- Exploring Dunk Tanks for Secure Transfers in High-Level Biosafety Labs

- The Role of Dunk Tanks in Maintaining Sterile Cleanroom Operations

- The Ultimate Guide to YOUTH Biosafety Dunk Tanks: Features, Benefits, and Applications

- The Science Behind Dunk Tanks: Enhancing Cleanroom Safety and Sterility

- Dunk Tanks vs. Other Sterilization Methods: A Comparative Analysis

- Dunk Tanks: A Key Component in Cleanroom Contamination Control

- Ensuring Biosafety with Dunk Tanks: A Vital Tool for Advanced Laboratories

- How Dunk Tanks Ensure Contamination-Free Transfers in Cleanrooms

- The Importance of Dunk Tanks in Sterile Cleanroom Environments