VHP Pass Box Features and Applications

Introduction to Cleanroom VHP Pass Box

The cleanroom VHP pass box (also known as a VHP chamber or VHP transfer box) is a device specifically designed to safely transfer small items between clean and non-clean areas in a cleanroom environment. It utilizes a VHP (Vaporized Hydrogen Peroxide) sterilization and flash evaporation system for efficient purification. It is equipped with an auto-pressure checking system for increased safety, and it comes with leak and fault alarms. The VHP pass box is ideally suited for use in biological laboratories and pharmaceutical factories.

Understanding VHP Sterilization

Vaporized Hydrogen Peroxide (VHP) sterilization, also known as vapor-phase hydrogen peroxide, takes advantage of the fact that hydrogen peroxide is more effective in killing bacterial spores when in a gaseous state than when in a liquid state at room temperature. This technique achieves complete sterilization and is commonly used in isolation rooms, isolators, transfer cabins, bag-in bag-out systems, and GMP workshop space sterilization.

Advantages of Vaporized Hydrogen Peroxide

Vaporized hydrogen peroxide has excellent sporicidal properties. As a disinfectant and sterilant medium, VHP (35%) is vaporized by a VHP generator for disinfection and sterilization of items. Experiments have shown that the sporicidal power of vaporized hydrogen peroxide is stronger than that of equivalent amounts of liquid hydrogen peroxide: The sterilization effect of 750-2000pg/L of vaporized hydrogen peroxide is equivalent to 300,000mg of liquid hydrogen peroxide.

Cost-Efficiency and Environmental Safety

Lower concentration sterilization also correspondingly decreases the material requirements and costs of disinfected surfaces. The operation temperature range for vaporized hydrogen peroxide sterilization can adapt between 4-80℃, with room temperature usually sufficient. When sterilizing, vaporized hydrogen peroxide is reduced to water and oxygen, and compared to other sterilization methods, there are no harmful residues, posing no danger to operators or the environment, similar to ozone sterilization.

Customizable Features of the Youth VHP Passbox

The Youth VHP Pass-Box uses Siemens automation control equipment to ensure the stable operation of each stage of the entire process. The advanced control system ensures reliable and efficient operation of the equipment, meeting the high standards and requirements of international customers. Mechanical pressure and bio-sealed doors can be selected, using imported high-density EPDM or silicone materials. The device’s interior can be equipped with four-sided UV disinfection.

HEPA Filtration and Secure Dual-Door System

During both the biological decontamination and exhaust phases, our Pass Box channels all gases within the chamber through H14-grade HEPA filters, ensuring stringent material contamination prevention.

The system boasts a stand-alone ventilation and exhaust module, complete with fans, pneumatic butterfly valves, and dedicated exhaust ductwork, facilitating swift purging of hydrogen peroxide gas from the chamber while safeguarding against HVAC system infiltration.

Engineered with a dual-door configuration, the inlet and outlet boast advanced pneumatic seals and lock systems, coupled with interlocking safety mechanisms, to guarantee secure operational procedures. The doors remain interlocked throughout the sterilization cycle, enhancing safety.

Pass Box

- Biological Decontamination

- H14 HEPA Filters

- Material Contamination Prevention

- Stand-Alone Ventilation

- Rapid Gas Replacement

- Dual-Door Structure

- Pneumatic Sealing and Locking

- Interlocking Safety Mechanisms

YOUTH VHP Passbox system has real-time monitoring capabilities for temperature, humidity, and pressure inside the cabin. The sterile transfer chamber is equipped with complete IQ, OQ, and PQ documentation and can provide on-site validation.

Has the function of saving and printing parameters for the bio-decontamination cycle.

Superior Dry, Sterile Environments

Enhanced Purification System:

YOUTH’s Pass Box utilizes a complete air intake and exhaust mechanism to provide a sealed sterilization stage with Vaporized Hydrogen Peroxide (VHP), ensuring unparalleled purification efficiency.

Energy-Efficient Operation:

Designed to be both economical and eco-friendly, the Pass Box operates with minimal energy consumption.

Condensation-Free Environment:

Both vaporization and gasification methods are available for selection. The gasification method utilizes VHP space sterilization technology, ensuring that the concentration of hydrogen peroxide gas is maintained above the saturation dew point level during the sterilization phase. This effectively prevents moisture condensation and ensures that the sterilization chamber remains dry at all times, greatly enhancing the speed and efficiency of the sterilization phase.

Precision Sterilization and Particle Filtration

Maximum Particle Size:

The pass box effectively filters particles, with a maximum particle size of < 0.5um, ensuring a clean transfer environment.

High Sterilization Efficiency:

The pass box achieves a sterilization efficiency exceeding 6Lg, ensuring thorough decontamination.

VHP Integration:

Incorporating Vaporized Hydrogen Peroxide (VHP) technology, VHP Pass box ensures effective sterilization of transferred items.

Online Concentration Control:

The pass box features real-time monitoring and control of VHP gas concentration during the sterilization process, optimizing performance and safety.

Sterilization Process

Pre-sterilization Preparation

Before commencing the VHP sterilization cycle, all materials slated for transfer are loaded into the passbox. The passbox door is securely sealed to prevent any potential contamination from the surrounding environment. Materials are often placed on trays or racks to allow for maximum exposure to the vaporized sterilant.

- Conditioning

The VHP generator begins by reducing the humidity levels inside the chamber, which allows the hydrogen peroxide vapor to distribute more evenly and enhances its microbial lethality. This conditioning phase prepares the passbox and its contents for an effective sterilization cycle. - Vapor Injection

Hydrogen peroxide solution is vaporized and injected into the passbox. This vapor fills the chamber, contacting all surfaces and penetrating any porous materials present. The concentration of hydrogen peroxide vapor is carefully monitored and maintained throughout the exposure phase to ensure effective sterilization. - Sterilant Exposure

The sterilizing agent, VHP, is kept at the prescribed concentration for a specific amount of time, known as the dwell time. This timeframe is essential to effectively destroy all microbial life forms, including bacteria, viruses, and fungi, within the passbox. - Aeration

After the exposure phase, the VHP is actively removed from the chamber. The passbox enters the aeration phase, wherein clean, filtered air is introduced to purge any remaining hydrogen peroxide vapor. This process continues until the residual concentration of the sterilant drops to a safe level, acceptable for handling by personnel and ensuring no damage to sensitive items.

Quality Control and Verification

Post-sterilization, it’s routine to perform biological and/or chemical indicators to verify the efficacy of the process. Only after the successful completion of these tests are the sterilized materials allowed to enter the cleanroom environment.

YOUTH’s VHP Pass Box (VHP Pass Through) offers advanced features for efficient, safe, and reliable decontamination and transfer of materials in controlled environments.

Applications of Cleanroom VHP Passbox

- In pharmaceuticals, the use of a VHP Passbox is crucial for maintaining the sterility of medications, particularly injectables and oral drugs. It serves as a barrier against microbes during the movement of materials, tools, and finalized products into a sterile cleanroom setting.

- Biotech laboratories rely on VHP Passboxes to maintain a contaminant-free environment crucial for cell culture and sensitive biological work, thereby preventing any inconsistencies in experiment outcomes.

- The healthcare sector, particularly surgical rooms and quarantine areas, prioritize sterility. VHP Passboxes play a key role in pre-sterilizing medical instruments and gear to reduce the likelihood of infection post-surgery.

- Research laboratories, especially in the fields of microbiology and genetics, depend on VHP Passboxes to maintain the sanctity of their studies by ensuring samples and equipment are not compromised by contaminants during their transfer to clean areas.

- Sterility is imperative in food science, both in R&D and production, to avert microbial contamination. VHP Passboxes ensure the secure transport of foodstuffs and analytical gadgets.

FAQs

How does YOUTH’s VHP Passbox ensure effective sterilization?

YOUTH’s VHP Passbox is designed with advanced technology that ensures complete and even distribution of vaporized hydrogen peroxide, along with precise control of humidity and temperature to maximize the efficacy of the sterilization process.

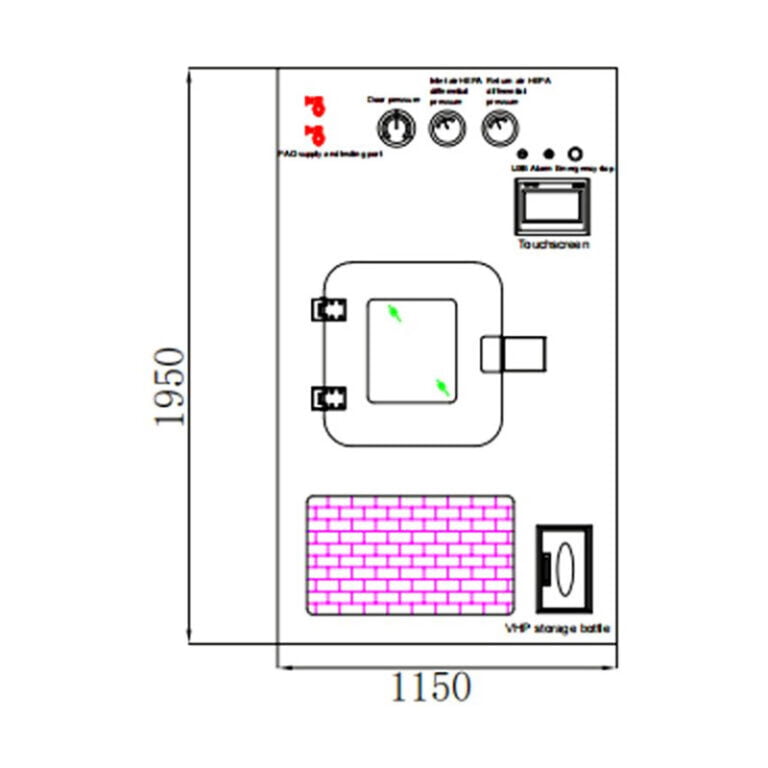

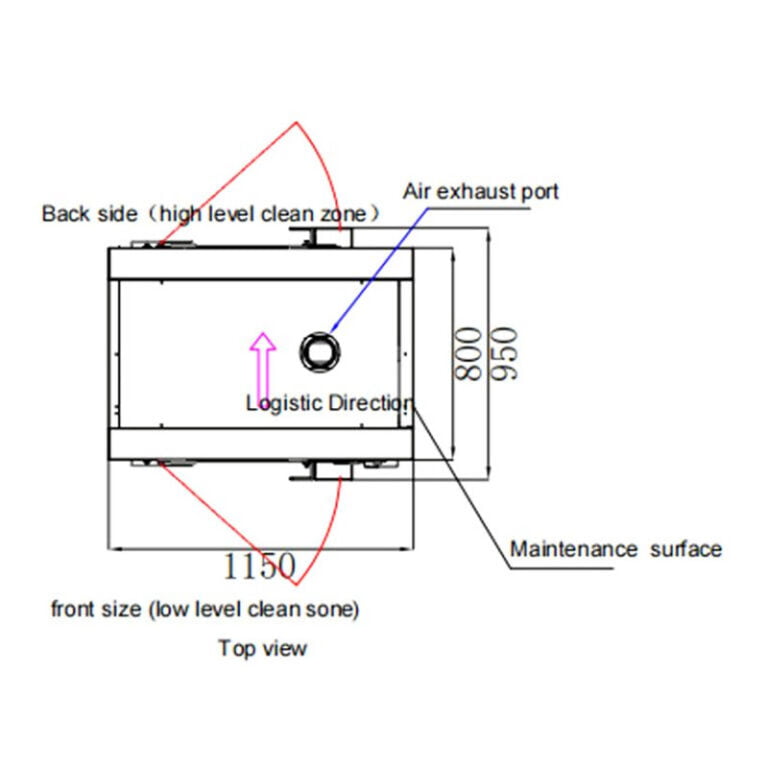

Can the VHP Passbox be customized to specific size requirements?

Yes, YOUTH offers customization options for the VHP Passbox to meet the size requirements of various cleanroom configurations and operational needs.

What types of industries can benefit from using a VHP Passbox?

Industries such as pharmaceuticals, biotechnology, healthcare, semiconductor manufacturing, aerospace, and any other fields that require controlled sterile environments can benefit from using a VHP Passbox.

How long does the sterilization cycle take in a YOUTH VHP Passbox?

The duration of the sterilization cycle can vary depending on the model and settings; however, YOUTH designs its VHP Passboxes to complete cycles efficiently while ensuring thorough sterilization.

What safety features are included in the VHP Passbox?

Safety features of YOUTH’s VHP Passbox include leak detection, door interlock systems to prevent opening during operation, and sensors to ensure the hydrogen peroxide levels are safe before the door is opened.

Are there any materials that cannot be sterilized in a VHP Passbox?

Materials sensitive to hydrogen peroxide or moisture should not be sterilized in a VHP Passbox. YOUTH can provide guidance on which materials are suitable for this process.

How is the VHP Passbox maintained and cleaned?

Regular maintenance includes checking seals and filters, ensuring that the hydrogen peroxide reservoir is filled, and wiping down internal surfaces with approved cleaning agents. YOUTH provides comprehensive maintenance instructions with each unit.

How can I purchase or get more information about YOUTH’s VHP Passbox?

You can contact YOUTH directly through our official website, phone, or email to inquire about purchasing options or to receive further information about our VHP Passbox.

Related Contents:

- Ultimate Guide to VHP Passbox Cleaning in Controlled Environments

- VHP Pass Box vs. Traditional Pass Box: A Comparative Analysis

- The Ultimate Guide to YOUTH’s VHP Pass Box: Ensuring Sterility in Cleanroom Environments

- Cost-Benefit Analysis of Investing in a VHP Pass Box

- User Manual Insights: Getting the Most Out of Your VHP Passbox

- The Ultimate Guide to YOUTH’s VHP Pass Box: Ensuring Sterility in Cleanroom Environments

- How to choose VHP Passbox?

- Ensuring Optimal Cleanroom Operations with VHP Pass Boxes

- Understanding the Mechanism of VHP Sterilization in Pass Boxes