A cleanroom door and window are specialized doors and windows that are designed for use in cleanrooms. Cleanrooms are specialized environments that are designed to minimize the presence of contaminants, such as dust, bacteria, and other particles. In a cleanroom, doors and windows are commonly used to provide access to the cleanroom, while maintaining the cleanliness of the environment.

Cleanroom doors and windows typically have a number of features that make them suitable for use in cleanroom environments. These features may include:

- Smooth, corrosion-resistant surfaces that are easy to clean and maintain

- Tight tolerances and precision dimensions for a clean, uniform appearance

- Lightweight, strong, and durable construction for long-term use

- Low-outgassing materials and finishes that do not release contaminants into the cleanroom environment

- Seamless, gasketed joints and connections that prevent the infiltration of contaminants

- Specialized hardware and mechanisms, such as locks, handles, and hinges, that are designed for use in cleanrooms

To choose the right cleanroom door and window for your needs, you should consider the specific requirements of your cleanroom. This may include factors such as the size and shape of the cleanroom, the level of cleanliness required, and the types of hazardous materials that will be used. You may also want to consider the manufacturer’s reputation and the door and window’s price and availability. By carefully evaluating these factors, you can determine the right cleanroom door and window for your cleanroom.

Understanding Cleanroom Door&Window

Cleanroom doors and windows serve as vital components in controlling contamination levels within cleanroom environments. These specialized access points effectively prevent the infiltration of airborne particles and microorganisms, ensuring the integrity of the controlled environment. They provide a physical barrier while allowing personnel, equipment, and materials to pass through seamlessly.

YOUTH’s cleanroom doors and windows are designed with meticulous attention to detail, considering factors such as air leakage, pressure differentials, and cleanliness requirements. By incorporating cutting-edge technology and adhering to industry standards and regulations, YOUTH delivers superior products that meet the most stringent cleanroom specifications.

Types of Cleanroom Door&Window

Hinged doors: These doors swing open on hinges, providing easy access and a tight seal when closed.

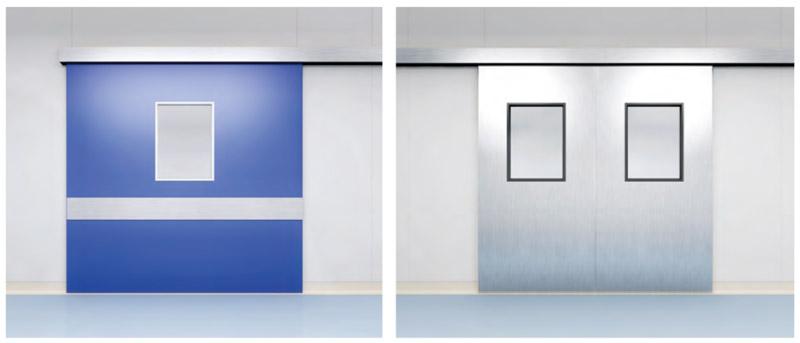

Sliding doors: Ideal for space optimization, sliding doors offer smooth operation and minimize airflow disruption.

Automatic doors: Equipped with sensors, these doors open and close automatically, enhancing workflow efficiency and maintaining cleanliness.

Hermetic doors: Engineered to create airtight seals, hermetic doors are essential in environments that demand absolute air containment.

Fire-rated doors: Designed to withstand and prevent the spread of fire, these doors provide an additional layer of safety in critical cleanroom areas.

Windows for cleanrooms: Transparent panels constructed with specialized materials, cleanroom windows facilitate visual inspection without compromising the controlled environment’s integrity.

Door Features for Cleanroom Applications:

Sleek and Seamless Design: The cleanroom doors feature a flush-mounted, hinged design combined with high-quality door hardware from Dorma. This combination not only ensures a sleek and seamless appearance but also adds to the overall aesthetic appeal of the cleanroom.

Enhanced Security and Safety: For added security and safety, an optional electrical interlock system is available with the cleanroom doors. This system helps regulate access by ensuring that only authorized personnel can enter or exit the cleanroom area, maintaining the integrity of the controlled environment.

Cohesive Viewing Window: The cleanroom doors come with a built-in viewing window that is also flush-mounted, providing a cohesive look. This window allows for observation and visual communication while maintaining the cleanliness and integrity of the cleanroom environment.

Tight Seal and Noise Reduction: To minimize noise transfer and maintain proper air pressure differentials, the cleanroom doors are equipped with an automatic drop seal. This feature ensures a tight seal when the door is closed, enhancing the overall noise control within the cleanroom.

Reliable Stainless Steel Door Handle: The cleanroom doors are fitted with a sturdy stainless steel door handle that offers a reliable grip. This durable handle provides ease of operation while ensuring long-lasting performance in the demanding cleanroom environment.

Sliding Door Option: In addition to the hinged design, there is also a sliding door option available for those who prefer a sliding mechanism. This alternative design provides flexibility and convenience, allowing for efficient use of space within the cleanroom area.

The cleanroom doors with these features are designed to meet the specific requirements of cleanroom environments, ensuring cleanliness, security, and functionality. Whether you choose the hinged or sliding option, these doors provide an excellent solution for maintaining the integrity and performance of your cleanroom facility.

Window Features for Cleanroom Applications:

Single-Glazed Window: The cleanroom window features a single-glazed design, providing a clear view while maintaining the required level of cleanliness and contamination control within the cleanroom environment.

Flush-Mounted Double-Glazed Window: For enhanced insulation and soundproofing, the cleanroom window can be equipped with a double-glazed configuration. The flush-mounted design ensures a seamless appearance while improving thermal efficiency and reducing noise transmission.

Condensation Prevention: To prevent condensation and maintain optimal visibility, the cleanroom window can be equipped with either a nitrogen fill or a silica gel pocket. These features help regulate moisture levels and ensure a clear and moisture-free viewing area.

Standard Size: The cleanroom window comes in a standard size of 1,160mm in width and 900mm in height. This site provides a balanced proportion and optimal visibility while maintaining the structural integrity of the cleanroom wall.

These window features are specifically designed for cleanroom applications, considering the need for cleanliness, insulation, and visibility. Whether you choose a single-glazed or double-glazed option, YOUTH’s cleanroom windows provide a reliable solution for maintaining the integrity and performance of your cleanroom environment.

Considerations for Choosing Cleanroom Door&Window

When selecting cleanroom doors and windows, several factors come into play:

Material selection: Depending on the application, materials like stainless steel, aluminum, or glass-reinforced polyester (GRP) can be chosen to meet specific requirements.

Air leakage and pressure differentials: The doors and windows must maintain a tight seal to prevent air infiltration, and pressure differentials must be carefully considered to ensure a controlled environment.

Cleanliness and sterilization: Cleanroom doors and windows must be easily cleanable, sterilizable, and free from particle-shedding materials.

Maintenance and durability: The doors and windows must be designed to withstand heavy use, frequent cleaning, and harsh chemicals, and require minimal maintenance.

Installation and Integration

YOUTH provides professional installation services, ensuring that all cleanroom doors and windows are installed correctly and seamlessly integrated with the cleanroom system. Thorough testing and validation ensure that the doors and windows meet the required specifications and standards.

Advancements and Innovations in Cleanroom Door&Window

YOUTH continues to innovate and improve its cleanroom doors and windows, incorporating advanced features to enhance efficiency, safety, and security. Some of the advancements include:

Energy-efficient solutions: Energy-efficient doors and windows minimize the amount of conditioned air that escapes the cleanroom, reducing energy consumption and costs.

Smart and automated features: Automatic doors and windows can be integrated with sensors and control systems, enabling remote operation and monitoring.

Anti-static and ESD protection: Doors and windows with anti-static and electrostatic discharge (ESD) protection prevent damage to sensitive equipment and materials.

Enhanced security measures: Doors and windows equipped with advanced locking systems and access control measures ensure that only authorized personnel can enter the cleanroom.

YOUTH’s Cleanroom Door&Window Solutions

YOUTH offers a wide range of cleanroom doors and windows, customizable to meet specific requirements and industry standards. Their products undergo rigorous quality assurance and certification processes to ensure that they meet the highest standards of quality and performance.

YOUTH’s client success stories showcase their exceptional products and services, from designing and building custom cleanroom solutions to providing ongoing maintenance and support.

FAQs:

Why are cleanroom doors and windows important in controlled environments?

Cleanroom doors and windows act as critical access points, maintaining the integrity of the controlled environment by preventing the infiltration of contaminants.

What types of cleanroom doors are available besides hinged and sliding doors?

In addition to hinged and sliding doors, there are automatic doors, hermetic doors, and fire-rated doors, each designed for specific cleanroom requirements.

Are cleanroom windows necessary in controlled environments?

Yes, cleanroom windows are essential as they allow visual inspection without compromising the controlled environment’s cleanliness and integrity.

How do cleanroom doors and windows contribute to energy efficiency?

Energy-efficient cleanroom doors and windows minimize the escape of conditioned air, reducing energy consumption and associated costs.

Can cleanroom doors and windows be integrated with smart technology?

Yes, modern cleanroom doors and windows can be equipped with sensors and control systems, allowing for remote operation and monitoring.

How do cleanroom doors and windows ensure cleanliness and sterilization?

Cleanroom doors and windows are designed with materials that are easily cleanable, sterilizable, and free from particle-shedding components.

What considerations should I keep in mind when selecting cleanroom doors and windows?

Material selection, air leakage, and pressure differentials, cleanliness and sterilization properties, and maintenance and durability are important factors to consider.

Can YOUTH provide installation services for cleanroom doors and windows?

Yes, YOUTH offers professional installation services, ensuring proper integration of doors and windows with the cleanroom system.

What certifications do YOUTH’s cleanroom doors and windows have?

YOUTH’s cleanroom doors and windows undergo rigorous quality assurance processes and meet industry standards and certifications for performance and reliability.

How do YOUTH’s cleanroom doors and windows enhance security?

YOUTH’s doors and windows are equipped with advanced locking systems and access control measures to ensure that only authorized personnel can enter the cleanroom.

Are there any innovative features available in YOUTH’s cleanroom doors and windows?

Yes, YOUTH’s cleanroom doors and windows incorporate features such as anti-static and electrostatic discharge (ESD) protection to safeguard sensitive equipment and materials.

Can YOUTH customize cleanroom doors and windows to fit specific requirements?

YOUTH offers a wide range of cleanroom doors and windows that can be customized to meet specific industry standards and individual project needs.

Related Contents:

- How to Choose the Right Cleanroom Door

- Ensuring Sterility in Cleanrooms: The Crucial Role of YOUTH Biosafety Airtight Doors

- Ensuring Sterility: The Role of YOUTH Biosafety Airtight Doors in Cleanrooms

- The Cleanroom Experience: A Guide to Safe and Efficient Operations

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Cleanroom Air Showers: Key Features and Benefits for Controlled Environments

- Fan Filter Units for Semiconductor Cleanrooms: A Must-Have Solution

- Fan Filter Units: Ensuring Sterile Conditions in Cleanroom Environments