What are cleanroom V-bank medium-efficiency air filters?

What are cleanroom V-bank medium-efficiency air filters?

What are cleanroom V-bank medium-efficiency air filters?

Cleanroom V-bank medium-efficiency air filters are a type of air filter used in cleanroom environments. They are designed to capture particles and contaminants that are larger than 1 micron. Cleanroom V-bank medium-efficiency air filters are used in facilities where air quality is crucial, such as healthcare facilities, pharmaceutical and biotechnology companies, and semiconductor manufacturing plants.

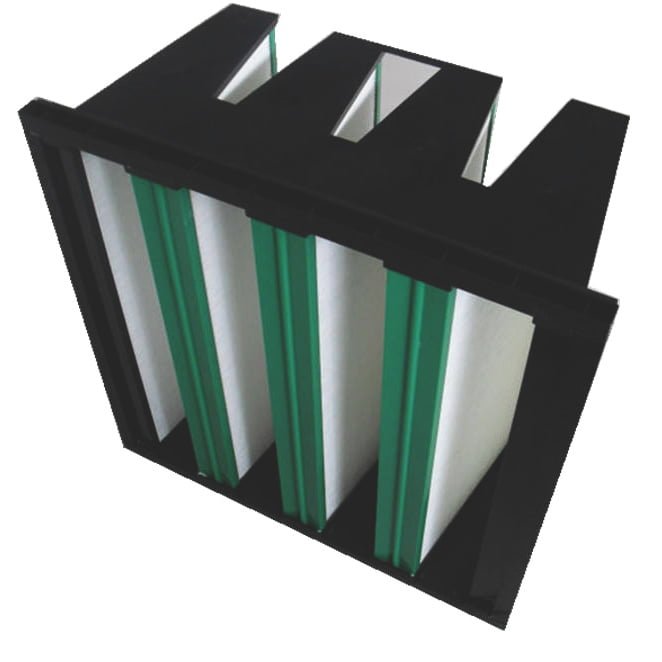

Cleanroom V-bank medium-efficiency air filters consist of a frame, media, and a faceguard. The frame is typically made of metal or plastic and is designed to hold the media in place. The media is the material that captures airborne particles and contaminants. The faceguard is an outer layer that protects the media from damage and helps to ensure even airflow.

What are cleanroom V-bank medium-efficiency air filters?

Airflow patterns – Cleanroom V-bank medium-efficiency air filters work by forcing air through a series of media layers, which trap airborne particles and contaminants. The airflow patterns within the filter are designed to ensure that all of the air passing through the filter comes into contact with the media, which improves the filter’s efficiency.

Filtration process – Cleanroom V-bank medium-efficiency air filters use a filtration process that captures particles and contaminants larger than 1 micron. The media within the filter is designed to attract and capture these particles, preventing them from circulating within the facility. The filtration process typically involves several layers of media, each with a different level of density and efficiency.

MERV rating system – The efficiency of cleanroom V-bank medium-efficiency air filters is rated using the Minimum Efficiency Reporting Value (MERV) system. The MERV rating indicates the filter’s ability to capture particles of different sizes. A higher MERV rating indicates a higher level of filtration efficiency.

What are cleanroom V-bank medium-efficiency air filters?

Improved air quality – Cleanroom V-bank medium-efficiency air filters improve air quality by capturing particles and contaminants that could be harmful to human health. This is especially important in healthcare facilities, where patients with weakened immune systems are more susceptible to airborne infections.

Reduced energy consumption – Cleanroom V-bank medium-efficiency air filters can also help to reduce energy consumption. By capturing particles and contaminants, the filters can help to reduce the load on HVAC systems, which can help to lower energy costs.

Extended equipment life – Cleanroom V-bank medium-efficiency air filters can also help to extend the life of equipment. By preventing particles and contaminants from circulating within the facility, the filters can help to reduce wear and tear on equipment, which can lead to longer equipment life and lower maintenance costs.

Increased productivity – Cleanroom V-bank medium-efficiency air filters can also help to increase productivity by providing a clean and healthy work environment. This can lead to fewer sick days and increased employee morale, which can help to improve productivity and efficiency.

what are the Applications of cleanroom V-bank medium-efficiency air filters?

Healthcare facilities – Cleanroom V-bank medium-efficiency air filters are commonly used in healthcare facilities to maintain a clean and healthy environment. They are used in patient rooms, operating rooms, and other areas where air quality is crucial.

Pharmaceuticals and biotechnology – Cleanroom V-bank medium-efficiency air filters are also used in the pharmaceutical and biotechnology industries to prevent contamination and maintain a sterile environment.

Semiconductor Manufacturing – Cleanroom V-bank medium-efficiency air filters are used in semiconductor manufacturing plants to prevent contamination and maintain a clean manufacturing environment.

Food and beverage industry – Cleanroom V-bank medium-efficiency air filters are also used in the food and beverage industry to prevent contamination and maintain a clean manufacturing environment.

What is the Maintenance of cleanroom V-bank medium-efficiency air filters?

Replacement schedule – Cleanroom V-bank medium-efficiency air filters should be replaced on a regular schedule to ensure maximum efficiency. The replacement schedule will depend on the type of filter, the facility, and the level of contaminants in the air.

Cleaning process – Cleanroom V-bank medium-efficiency air filters can also be cleaned to extend their life. The cleaning process will depend on the type of filter and the level of contaminants in the air.

Monitoring – Cleanroom V-bank medium-efficiency air filters should be monitored regularly to ensure they are functioning properly. This can be done through regular inspections and testing.

Conclusion – Cleanroom V-bank medium-efficiency air filters are an essential component of maintaining a clean and healthy environment in a variety of industries. They improve air quality, reduce energy consumption, extend equipment life, and increase productivity. Understanding how they work and their benefits can help facility managers make informed decisions about their air filtration systems.

| Type | VS-M6 | VS-F7 | VS-F9 |

| Class EN779 | M6 | F7 | F9 |

| Efficiency EN779 [%] | 65 % | 85 % | 95 % |

| Initial-ΔP[Pa](A/B) | 65 / 120 | 75 / 140 | 85 / 165 |

| Rec. finalΔP | 600 | 600 | 600 |

| Max. temp. [°C] | 65° | 65° | 65° |

| Model (E=efficiency N=V quantity) | Width | Height | Depth | Nominal airflow [m³/h] | V quantity |

| VS592592292-E (M6-F9) N5 | 592 | 592 | 292 | 3000 | 5 |

| VS592592292-E (M6-F9) N4 | 490 | 592 | 292 | 2400 | 4 |

| VS287592292-E (M6-F9) N4 | 287 | 592 | 292 | 1200 | 4 |

And the V-bank filter fits into the standard bag filter mounting frame, so the existing bag filter in the original clean room can be upgraded to the higher efficiency V-Bank air filter with a simple installation operation.

Full-size standard: 24″ x 24″ (WxH), 12″ deep

Frame (head frame) material: recycled plastic

Media: Fiberglass, Synthetic, or Fiberglass/Activated Carbon

FAQs

What is a cleanroom V-bank medium-efficiency air filter?

A cleanroom V-bank medium-efficiency air filter is a type of air filter used in cleanroom environments to capture particles and contaminants larger than 1 micron.

How does a cleanroom V-bank medium-efficiency air filter work?

A cleanroom V-bank medium-efficiency air filter works by using multiple layers of media with varying densities and efficiencies to capture particles and contaminants as air passes through the filter.

What is the MERV rating system?

The MERV rating system is used to measure the efficiency of air filters, including cleanroom V-bank medium-efficiency air filters. A higher MERV rating indicates a higher level of filtration efficiency.

What are the benefits of using cleanroom V-bank medium-efficiency air filters?

Cleanroom V-bank medium-efficiency air filters can improve air quality, reduce energy consumption, extend equipment life, and increase productivity.

What industries use cleanroom V-bank medium-efficiency air filters?

Cleanroom V-bank medium-efficiency air filters are commonly used in healthcare facilities, pharmaceutical and biotechnology industries, semiconductor manufacturing plants, and the food and beverage industry.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- Mastering Clean Room Technology with Fan Filter Units (FFUs)

- A Comprehensive Guide to Indoor Air Quality (IAQ)

- Fan Filter Units: Key to Quality Control in Cleanroom Manufacturing Processes

- Fan Filter Units: Ensuring Sterile Conditions in Cleanroom Environments

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Achieving Precision and Cleanliness: The Power of Fan Filter Units

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification