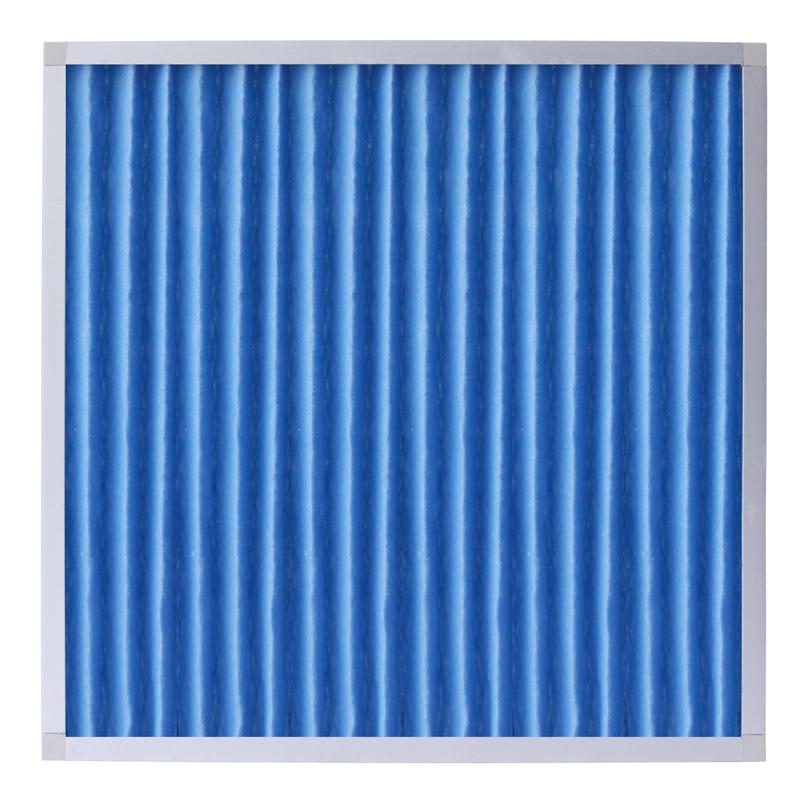

What is the Cleanroom Panel Pre-Air Filter?

Cleanroom panel pre-air filters are an essential component of any HVAC system, especially in cleanroom environments. These filters are designed to remove large particles from the air, ensuring that the air entering the cleanroom is of the highest quality. In this article, we will discuss the different types of cleanroom panel pre air filters, their features, benefits, applications, and factors to consider when choosing one.

How many Types of Cleanroom Panel Pre Air Filters?

The two most common types of cleanroom panel pre air filters are fiberglass and polyester. Fiberglass filters are made from strands of glass, while polyester filters are made from synthetic fibers. Fiberglass filters are more common and have a higher dust holding capacity, but polyester filters have a lower pressure drop and can be washed and reused.

What are the Features of Cleanroom Panel Pre-Air Filters?

Cleanroom panel pre-air filters have several features that make them ideal for cleanroom environments.

They have a high dust holding capacity, which means they can capture more particles before needing to be replaced. They also have a low pressure drop, which means they allow air to flow freely through the filter, reducing strain on the HVAC system. Additionally, they have a high filtration efficiency, which means they capture a high percentage of particles as they pass through the filter.

what are Benefits of Using Cleanroom Panel Pre Air Filters?

There are several benefits to using cleanroom panel pre air filters in HVAC systems. Firstly, they can increase the lifespan of equipment by reducing the amount of dust and debris that enters the system. Secondly, they can improve indoor air quality by removing pollutants from the air. Finally, they can reduce energy costs by improving the efficiency of the HVAC system.

What are the Applications of Cleanroom Panel Pre Air Filters?

Cleanroom panel pre air filters are commonly used in industries that require high levels of cleanliness, such as the pharmaceutical, food and beverage, and electronics industries. In the pharmaceutical industry, these filters are used to maintain sterile environments and prevent contamination. In the food and beverage industry, they are used to prevent the spread of bacteria and other contaminants. In the electronics industry, they are used to prevent the buildup of dust and other particles that can damage sensitive equipment.

How to Choosing Cleanroom Panel Pre Air Filters?

When choosing a cleanroom panel pre air filter, there are several factors to consider. Firstly, filtration efficiency is important, as it determines the level of protection provided by the filter. Secondly, airflow capacity is important, as it determines how much air can pass through the filter without causing a pressure drop. Finally, the type of application is important, as different industries have different requirements for cleanliness.

What is Maintenance of Panel Pre Air Filters?

Regular maintenance is important to ensure the longevity and efficiency of cleanroom panel pre air filters. Filters should be cleaned or replaced on a regular schedule to prevent the buildup of dust and other particles. The frequency of cleaning or replacement depends on the application and the environment in which the filter is used.

FAQs

What is a cleanroom panel pre-air filter?

A cleanroom panel pre-air filter is a type of filter used in HVAC systems to remove large particles from the air before it enters a cleanroom environment.

What is the difference between fiberglass and polyester panel pre-air filters?

Fiberglass filters are made from strands of glass, while polyester filters are made from synthetic fibers. Fiberglass filters have a higher dust holding capacity, while polyester filters have a lower pressure drop and can be washed and reused.

What are the benefits of using panel pre-air filters?

Cleanroom panel pre-air filters can increase the lifespan of equipment, improve indoor air quality, and reduce energy costs.

What industries commonly use cleanroom panel pre-air filters?

Industries that require high levels of cleanliness, such as the pharmaceutical, food and beverage, and electronics industries, commonly use cleanroom panel pre-air filters.

How often should cleanroom panel pre-air filters be cleaned or replaced?

The frequency of cleaning or replacement depends on the application and the environment in which the filter is used. It is important to follow the manufacturer’s recommendations and perform regular maintenance to ensure the longevity and efficiency of the filter.

| Type: | PF-G4 | PF-M5 |

| Class EN779 | G4 | M5 |

| Efficiency against synthetic dust [%] | 91% | 97% |

| Initial-ΔP [Pa] | 25 | 60 |

| Recommended finalΔP [Pa] | 250 | 400 |

| Max. temp. [°C] | 70° | 70° |

| Model (E=efficiency) | Dimensions [mm] | Nominal airflow[m3/h] | ||

| Width | Height | Depth | ||

| PF28759246-E (G4/M5) | 287 | 592 | 46 | 1600 |

| PF28759246-E (G4/M5) | 592 | 592 | 46 | 3200 |

| Customized Filters Type :150≤W≤1184,150≤H≤1184 and 10≤D≤292. | ||||

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- Mastering Clean Room Technology with Fan Filter Units (FFUs)

- Mastering Air Filter Selection: A Comprehensive Guide

- Fan Filter Units: Balancing Efficiency and Cost-Effectiveness

- A Comprehensive Guide to Indoor Air Quality (IAQ)

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs