What’s the cleanroom flooring?

Cleanroom flooring refers to the specialized flooring systems designed and installed in cleanroom environments. Cleanrooms require flooring that meets specific criteria to maintain cleanliness, hygiene, and control over contamination.

Cleanroom flooring is engineered to minimize the generation and accumulation of particles, facilitate easy cleaning and maintenance, provide electrostatic discharge (ESD) protection, and offer durability in demanding cleanroom conditions. These flooring systems are typically constructed using materials that are non-porous, non-shedding, and resistant to chemicals and wear.

How many types of cleanroom flooring?

There are various types of cleanroom flooring options available, depending on the specific requirements of the cleanroom and the industry it serves. Some common types of cleanroom flooring include:

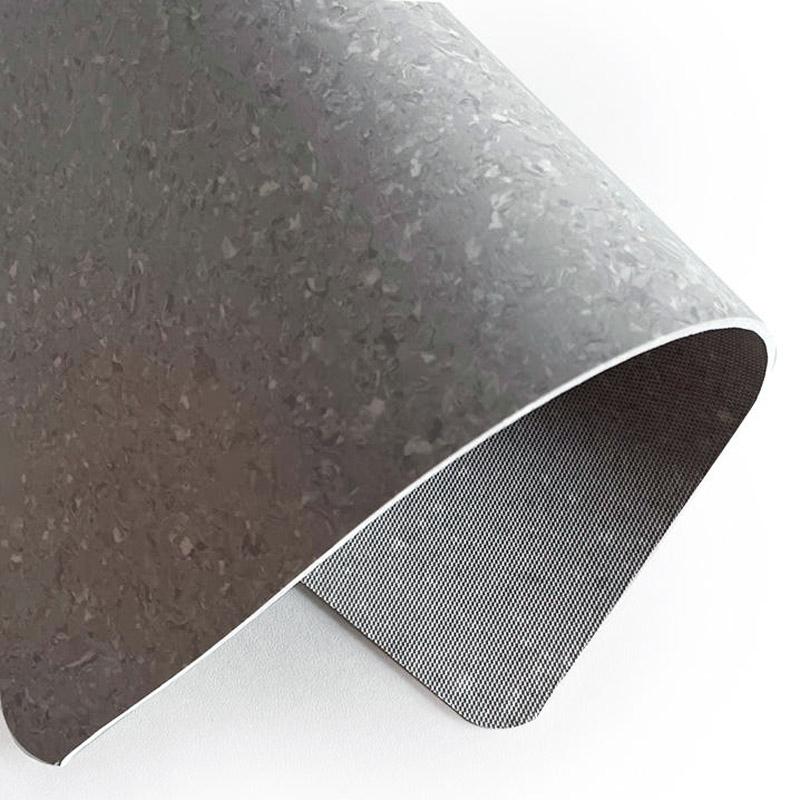

Vinyl Flooring: Vinyl flooring is a popular choice for cleanrooms due to its durability, ease of cleaning, and resistance to chemicals. It can be installed as tiles or sheets, offering a seamless and smooth surface that prevents particle accumulation and facilitates effective cleaning.

Epoxy Flooring: Epoxy flooring is a high-performance flooring solution commonly used in cleanrooms. It provides a seamless, non-porous surface that is resistant to chemicals, abrasion, and microbial growth. Epoxy flooring can be customized to meet various cleanroom specifications, including ESD protection.

Rubber Flooring: Rubber flooring is slip-resistant, durable, and has excellent shock-absorbing properties. It is often used in cleanrooms with heavy equipment.

Conductive Flooring: Conductive flooring is designed to dissipate static electricity and prevent electrostatic discharge (ESD) in sensitive cleanroom environments, particularly in electronics and semiconductor manufacturing. It consists of specialized materials that offer controlled conductivity to protect electronic equipment and minimize the risk of damage.

Polyurethane Flooring: Polyurethane flooring is an excellent choice for cleanrooms that require a high level of chemical resistance. It is also slip-resistant and can withstand heavy loads.

Raised Access Flooring: Raised access flooring systems feature modular panels that create an elevated platform above the subfloor. This type of flooring allows for the concealment of utility services such as electrical wiring, data cables, and HVAC systems. Raised access flooring enhances cleanroom functionality by facilitating easy access, maintenance, and adaptability to changing cleanroom requirements.

Cleanroom flooring systems are typically installed with meticulous attention to detail, ensuring proper sealing and integration with other cleanroom components such as walls, partitions, and HVAC systems. They play a critical role in maintaining the desired cleanliness, minimizing particle generation, and ensuring a controlled environment within the cleanroom.

It’s important to select and install cleanroom flooring that complies with industry standards and cleanroom classifications to meet the specific needs of the cleanroom facility and the processes carried out within it.

Factors to Consider when Choosing Cleanroom Flooring

Choosing the right cleanroom flooring is crucial to ensure that it meets the specific requirements of the cleanroom.

A. Level of Cleanliness

The level of cleanliness required for a cleanroom will determine the type of flooring needed. For example, a Class 100 cleanroom requires flooring that is easy to clean and free of particles.

B. Chemical Resistance

Cleanroom flooring must be resistant to chemicals used in the manufacturing process. The type of chemicals used will determine the type of flooring required.

C. Durability

The flooring must be durable and able to withstand heavy traffic and equipment.

D. Static Control

Static control is essential in cleanrooms that handle sensitive electronics. The flooring must be able to dissipate static electricity to prevent damage to the products.

Installation and Maintenance of Cleanroom Flooring

Installing and maintaining cleanroom flooring is crucial to ensure that it performs as expected.

A. Pre-Installation Preparation

Before installing cleanroom flooring, the area must be thoroughly cleaned and prepared. Any contaminants must be removed, and the surface must be level.

B. Installation Process

The installation process for cleanroom flooring will vary depending on the type of flooring chosen. It is recommended to hire professionals experienced in cleanroom installations to ensure proper installation and adherence to cleanroom standards.

C. Maintenance and Cleaning

Regular maintenance and cleaning are essential to prolong the lifespan and performance of cleanroom flooring. This includes daily cleaning routines, periodic deep cleaning, and inspections for any damages or wear.

Cost of Cleanroom Flooring

When considering cleanroom flooring, it’s important to evaluate the cost implications.

A. Initial Cost

The initial cost of cleanroom flooring includes the purchase of materials and professional installation. Different types of cleanroom flooring have varying price ranges, so it’s crucial to consider the specific requirements of the cleanroom and budget constraints.

B. Long-Term Cost

The long-term cost of cleanroom flooring includes maintenance, repairs, and potential replacements. Choosing a high-quality, durable flooring material can minimize long-term costs by reducing the need for frequent repairs or replacements.

FAQs:

What is cleanroom flooring?

Cleanroom flooring refers to specialized flooring materials and systems designed for cleanroom environments. It is an essential component in maintaining a controlled and contaminant-free workspace.

How does cleanroom flooring prevent contamination?

Cleanroom flooring prevents contamination by being non-porous and easy to clean. It inhibits the growth of microorganisms, resists chemical spills, and minimizes the generation of particles that could compromise the cleanliness of the environment.

Can I use regular flooring materials in a cleanroom?

No, regular flooring materials are not suitable for cleanrooms. Cleanroom flooring must meet specific requirements such as being resistant to chemicals, static-free, and easy to clean, which regular flooring materials may not fulfill.

What are the advantages of vinyl flooring in cleanrooms?

Vinyl flooring is a popular choice for cleanrooms due to its durability, ease of maintenance, and chemical resistance. It provides a seamless and hygienic surface that is capable of withstanding heavy foot traffic.

Is epoxy flooring suitable for all types of cleanrooms?

Epoxy flooring is a versatile option that can be suitable for various cleanroom applications. However, the specific requirements of the cleanroom, such as the level of cleanliness and chemical exposure, should be considered when choosing the flooring type.

How can I determine the level of cleanliness required for my cleanroom flooring?

The level of cleanliness required for cleanroom flooring depends on the industry standards and regulations applicable to your specific cleanroom application. Consult with experts or refer to industry guidelines to determine the appropriate cleanliness level.

Can cleanroom flooring be customized to meet specific needs?

Yes, cleanroom flooring can be customized to meet specific needs. Different flooring materials offer various features and properties that can be tailored to suit the requirements of a particular cleanroom environment.

How often should cleanroom flooring be cleaned?

Cleanroom flooring should be cleaned regularly as part of a routine maintenance schedule. The frequency of cleaning will depend on factors such as the level of foot traffic, the nature of the work being performed, and the cleanroom classification.

Are there any special cleaning products or procedures for cleanroom flooring?

Yes, cleanroom flooring may require specific cleaning products and procedures to ensure optimal cleanliness and integrity. It is essential to follow the manufacturer’s recommendations and consult with cleanroom experts for appropriate cleaning protocols.

Can cleanroom flooring be repaired if damaged?

In most cases, cleanroom flooring can be repaired if damaged. However, the extent and type of damage will determine the repair options available. It is recommended to consult with cleanroom flooring specialists to assess and address any damage properly.

Does cleanroom flooring require regular inspections?

Yes, regular inspections of cleanroom flooring are necessary to identify any signs of wear, damage, or potential issues. Scheduled inspections help in maintaining the performance and longevity of the flooring and allow for timely repairs or replacements, if required.

How long does cleanroom flooring typically last?

The lifespan of cleanroom flooring can vary depending on factors such as the type of flooring, the level of maintenance, and the intensity of use. High-quality cleanroom flooring, when properly installed and maintained, can last for many years before requiring replacement.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- How to Choose the Right Cleanroom Door

- Navigating Biosafety Cabinet Classes: A Complete Overview

- The Cleanroom Experience: A Guide to Safe and Efficient Operations

- Pass-Through Systems Demystified: Types and Applications

- Understanding Cleanrooms: Types and Their Significance

- How to Control Clean Room Temperature: A Comprehensive Guide

- The Ultimate Guide to YOUTH Modular Cleanrooms: Precision, Flexibility, and Efficiency

- What are the Materials Used in Cleanroom Building?