What are the panels for the cleanroom wall and ceiling?

Cleanroom wall and ceiling panels are specialized components designed to create and maintain controlled environments in cleanrooms. They are made of materials that meet cleanliness standards and offer functions like separation, contamination control, and insulation. These panels have smooth, non-porous surfaces, reducing particle buildup and microbial growth. They are also structurally robust and durable to withstand cleanroom conditions. Some panels provide thermal and acoustic insulation. YOUTH offers a variety of cleanroom panel solutions, ensuring cleanliness, durability, insulation, and customization. Using high-quality panels ensures a clean and compliant environment for sensitive processes and products.

Factors to Consider when Choosing Cleanroom Panels

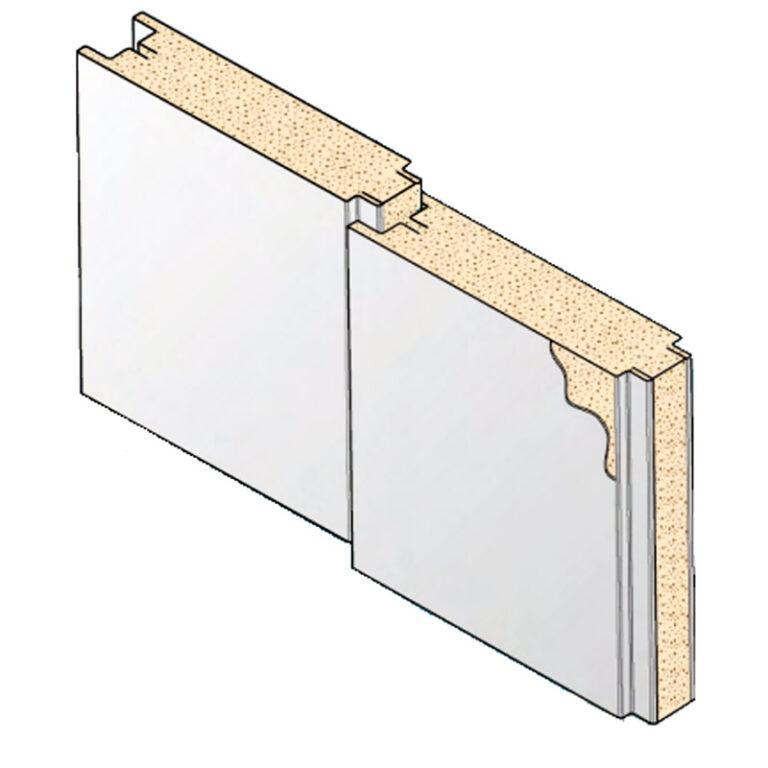

Cleanroom wall panels are an essential component of any cleanroom facility. They are designed to provide a durable and reliable barrier to prevent contaminants from entering the controlled environment. To meet these requirements, wall panels typically use materials such as 0.5-1.2mm thick color-coated steel plate, stainless steel, aluminum plate, or 4mm HPL panel. The sandwich materials used in the panels include high-density rock wool, magnesium oxide board, aluminum honeycomb, or paper honeycomb. The thickness, length, width, and color of the panels are customized to meet the specific needs of each project.

Similarly, the cleanroom ceiling panels are also designed to prevent the entry of contaminants into the controlled environment. They can be made of the same materials as the wall panels or one-piece PUF (Polyurethane Form) injection-molded polyurethane panels. These panels have a thickness of 42-100mm, are lightweight, easy to install, and have a better load-bearing capacity than other panel materials.

Different Types of Cleanroom Panels

Cleanrooms require specialized panels that meet stringent cleanliness and performance standards. Here are different types of cleanroom panels commonly used in various industries:

Aluminum Honeycomb Panels :

- These panels consist of aluminum sheets bonded to a honeycomb core structure.

- They offer excellent structural integrity, lightweight construction, and high durability.

- Aluminum honeycomb panels provide enhanced thermal insulation and sound absorption properties.

Paper Honeycomb Panels:

- Paper honeycomb panels are constructed using a core made of honeycomb-shaped paper cells.

- They offer good insulation properties and are lightweight yet robust.

- These panels are cost-effective and commonly used in cleanrooms with low particulate generation requirements.

Rock Wool Panels:

- Rock wool panels are made from natural rock fibers bound together with a binder material.

- They provide excellent thermal insulation, fire resistance, and sound absorption capabilities.

- Rock wool panels are commonly used in cleanrooms requiring high fire safety and acoustic properties.

Rock Wool with Gypsum Panels:

- These panels combine the benefits of rock wool insulation with a gypsum board facing.

- They offer enhanced fire resistance, improved soundproofing, and better resistance to moisture and humidity.

- Rock wool with gypsum panels are commonly used in cleanrooms where fire safety and moisture control are critical.

High-Pressure Laminate (HPL) Panels:

- HPL panels are constructed by applying high-pressure and heat to multiple layers of resin-impregnated paper.

- They offer excellent resistance to chemicals, scratches, impact, and moisture.

- HPL panels are known for their durability, easy maintenance, and aesthetic appeal, making them suitable for cleanrooms with strict cleanliness and design requirements.

Polyurethane Foam (PUF) Panels:

- PUF panels consist of a polyurethane foam core sandwiched between metal or other rigid facing materials.

- They provide superior thermal insulation properties, helping to maintain a controlled temperature environment.

- PUF panels offer excellent structural stability, moisture resistance, and thermal efficiency, making them ideal for cleanrooms requiring precise temperature control.

Each type of cleanroom panel has unique characteristics and suitability for specific cleanroom applications. Choosing the right panel type depends on factors such as cleanliness requirements, thermal insulation needs, fire safety regulations, and aesthetic preferences. At YOUTH, we offer a comprehensive range of cleanroom panels, including these different types, to meet diverse cleanroom needs and deliver optimal performance and cleanliness.

YOUTH's Panel Solutions for Cleanroom Walls and Ceilings

YOUTH takes pride in its cutting-edge technology and expertise when it comes to cleanroom panels. Their panel systems are meticulously designed and manufactured to meet the rigorous demands of cleanroom environments. With advanced manufacturing processes and the use of high-quality materials, YOUTH ensures that their panels surpass industry standards.

YOUTH’s cleanroom panels are customizable to fit specific requirements. From size and color to surface finish and edge profiles, YOUTH offers a wide range of options to create a cleanroom environment that aligns with your unique needs and preferences. Their team of experts works closely with clients to understand their specific challenges and deliver tailored solutions that guarantee optimal performance and functionality.

The Benefits of YOUTH's Panel Systems

Quick and Easy Installation: Our cleanroom system is specifically designed for fast and hassle-free installation, ensuring that you can set up your cleanroom swiftly without compromising on quality.

Time-Saving Prefabricated Panels: Our panels are prefabricated, meaning they come ready-made and can be easily installed. This saves valuable time and guarantees precise panel construction, ensuring a high level of accuracy.

Concealed Electrical Wiring: We understand the importance of maintaining a clean and organized appearance in your cleanroom. That’s why all electrical wiring is cleverly concealed within the panels, resulting in a streamlined and clutter-free environment. This not only enhances the aesthetic appeal but also minimizes the risk of contamination.

Self-Supporting and Easy to Dismantle: Our cleanroom system is self-supporting, eliminating the need for additional support structures during installation. Moreover, it is designed to be easily dismantled, allowing for convenient reconfiguration or expansion of your cleanroom as per your evolving needs.

Flawless Flush Surface and Corner Coving Finishing: Our panels boast a flawless flush surface finish, leaving no room for gaps or crevices where dust or contaminants can accumulate. Additionally, the inclusion of corner coving ensures smooth transitions between wall and ceiling panels, enhancing the overall cleanliness and hygiene of your cleanroom.

Adaptability to Layout Changes: We understand that your cleanroom requirements may change over time. That’s why our system is specifically engineered to accommodate layout changes and future expansions, providing you with the flexibility you need as your business evolves.

Integrated Panel Return Air Riser: Maintaining optimal air quality and minimizing contamination are paramount in cleanroom environments. That’s why our system features a built-in panel return air riser, effectively managing air circulation. Additionally, the concealed design of the return air duct further reduces the risk of dust deposits.

Seamless Single Piece Wall Corner: Say goodbye to the hassle of additional corner pieces. Our cleanroom system includes a single-piece wall corner, ensuring a seamless and cohesive appearance throughout your cleanroom. This meticulous attention to detail enhances the overall cleanliness and aesthetics of the space.

At YOUTH, we prioritize the efficiency, cleanliness, and adaptability of our cleanroom solutions. With our easy installation process, prefabricated panels, concealed wiring, self-supporting structure, flawless finishing, and accommodating features, we offer a comprehensive cleanroom system that meets your unique requirements. Experience the difference with YOUTH and create a cleanroom environment that exceeds your expectations.

FAQs

Cleanroom panels are specialized wall and ceiling components designed to create controlled environments with stringent cleanliness standards. They provide physical separation, contamination control, and insulation within cleanroom spaces.

The selection of panels for cleanroom walls and ceilings is crucial because they contribute to maintaining cleanliness, structural integrity, insulation, and overall performance of the cleanroom environment.

When selecting cleanroom panels, factors such as cleanliness and contamination control, structural integrity, thermal and acoustic insulation, ease of installation and maintenance, and customization options should be considered.

YOUTH offers a range of cleanroom panels, including rigid wall panels, flexible wall panels, modular ceiling panels, and specialized panels for unique requirements like fire-rated panels or antimicrobial panels.

Rigid wall panels provide maximum protection against contaminants and offer exceptional strength and durability. Flexible wall panels, on the other hand, offer versatility and adaptability, making them ideal for areas that require frequent modifications or reconfigurations.

YOUTH’s panel systems offer enhanced cleanliness and contamination control, superior structural integrity and durability, efficient thermal and acoustic insulation, ease of installation and maintenance, and customization options to meet specific requirements.

Yes, YOUTH’s panel systems can be customized to fit specific cleanroom requirements. They offer options for size, color, surface finish, and edge profiles to create a cleanroom environment that aligns with your unique needs and aesthetics.

YOUTH’s panel systems are manufactured using advanced technology and high-quality materials. They undergo rigorous testing and adhere to industry standards and regulations to ensure compliance with cleanroom requirements.

Yes, YOUTH’s panel systems offer efficient thermal insulation, helping to maintain stable temperatures within the cleanroom environment and provide energy efficiency.

Absolutely, YOUTH’s panel systems provide acoustic insulation, reducing noise transmission and creating a quieter and more productive cleanroom environment.

YOUTH’s panel systems are built to withstand the demands of cleanroom environments, providing long-lasting performance and durability. The lifespan of the panels depends on factors such as usage, maintenance, and environmental conditions.

To get started with YOUTH’s panel systems, reach out to their team of experts who will assess your specific requirements and provide tailored solutions. Contact YOUTH today to discuss your cleanroom needs and explore their range of panel options.

Related Contents:

- How to Decide on the Right Wall Material for Your Cleanroom

- The Cleanroom Experience: A Guide to Safe and Efficient Operations

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- What are the Materials Used in Cleanroom Building?

- Fan Filter Units for Semiconductor Cleanrooms: A Must-Have Solution

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification

- The Clean Team: Key Players in Cleanroom Operations