Understanding VHP Technology

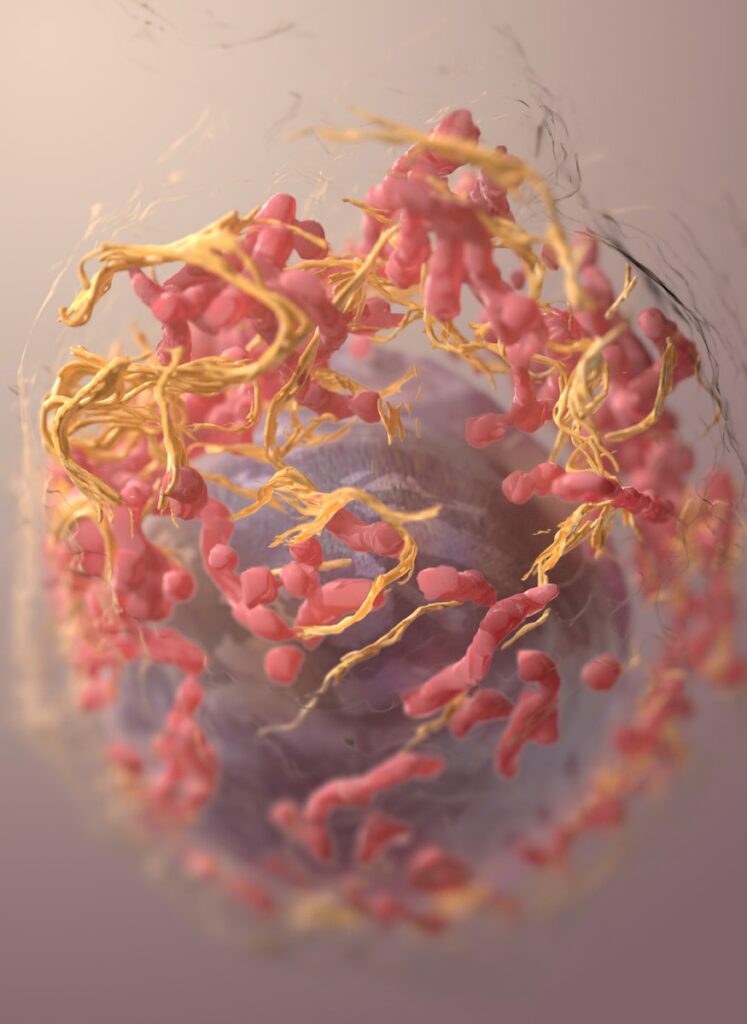

Vaporized Hydrogen Peroxide (VHP) technology represents a forefront of modern sterilization methods, particularly valued for its efficacy and efficiency in decontamination cycles. By converting liquid hydrogen peroxide into a vaporous state, VHP ensures a thorough sterilizing process suitable for a variety of sensitive environments like cleanrooms and healthcare settings.

The Mechanics of VHP Decontamination Cycles

The decontamination cycle using VHP involves multiple phases – conditioning, bio-decontamination, and aeration. The conditioning phase ensures that environmental conditions are optimal for vapor distribution. Bio-decontamination is where the actual sterilization occurs, and the aeration phase removes any remaining VHP, ensuring the area is safe for use.

Key Factors for Effective Cycles:

- Concentration: Proper VHP concentration is crucial for effective decontamination.

- Distribution: The system must evenly distribute VHP within the environment to ensure contact with all surfaces.

- Exposure Time: An adequate exposure time is necessary to guarantee the destruction of all microorganisms.

Benefits of VHP Decontamination Cycles

- Room Temperature Decontamination: VHP operates effectively at room temperature, avoiding damage to heat-sensitive equipment.

- Fast Turnaround Time: The VHP cycle is considerably shorter than traditional methods, like ethylene oxide sterilization.

- Material Compatibility: VHP does not corrode metals and is less damaging to materials than other gases like formaldehyde.

- Eco-Friendly: Decomposing into water vapor and oxygen, VHP leaves no harmful residues, minimizing environmental impact.

Implementing VHP Cycles in Your Facility

To adopt VHP decontamination cycles for your facility:

- Assessing Facility Design: Ensure the design of your facility can accommodate VHP’s distribution requirements.

- Choosing the Right Equipment: Automated VHP systems can optimize the decontamination process for consistency and reliability.

- Training and Procedures: Staff must be trained on proper procedures to handle and operate VHP systems safely.

Conclusion: Achieving Sterility with VHP Decontamination

VHP decontamination cycles provide a high-efficiency solution to achieving sterility in critical environments. When implemented correctly, VHP technology not only ensures compliance with strict regulatory standards but also makes a facility more sustainable and safe for both personnel and products.

Related Contents:

- Ultimate Guide to VHP Passbox Cleaning in Controlled Environments

- The Ultimate Guide to YOUTH’s VHP Pass Box: Ensuring Sterility in Cleanroom Environments

- User Manual Insights: Getting the Most Out of Your VHP Passbox

- The Ultimate Guide to YOUTH’s VHP Pass Box: Ensuring Sterility in Cleanroom Environments

- VHP Pass Box vs. Traditional Pass Box: A Comparative Analysis

- The VHP Passbox Decontamination Process Explained

- Understanding the Mechanism of VHP Sterilization in Pass Boxes

- Advanced Sterilization with YOUTH’s Vaporized Hydrogen Peroxide (VHP) Generators

- Cost-Benefit Analysis of Investing in a VHP Pass Box