What is the pharmaceutical decontamination water shower?

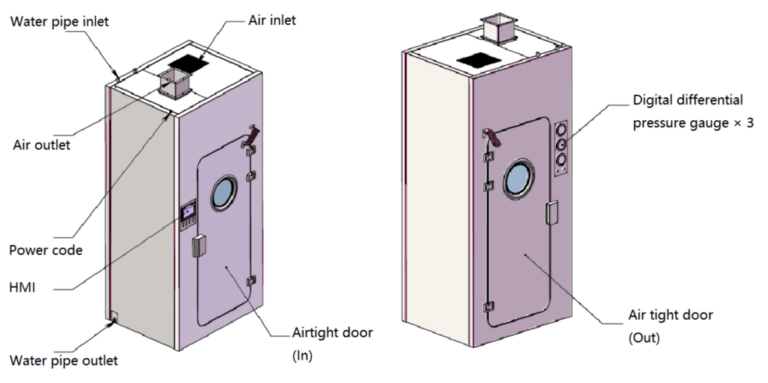

The pharmaceutical decontamination water shower is a biosafety system designed for P3/P4 biological labs and high-demand pharmaceutical workshops. Crafted from AISI304 stainless steel, it features airtight doors to prevent pollutant leakage. Components include inner cabins, air supply, exhaust, drainage, shower devices, and lighting. It boasts built-in filters, disinfection, leak detection, automatic water temperature control, and emergency escape systems. The control system covers interlocking, personnel and time control, alarms, operation records, and data transmission.

Youth’s water shower feature

The water shower cabin includes a control system, a frame, an inner chamber, supply HEPA, exhaust HEPA, double-sided airtight doors, pressure difference detection, drainage, shower devices and lighting, etc.

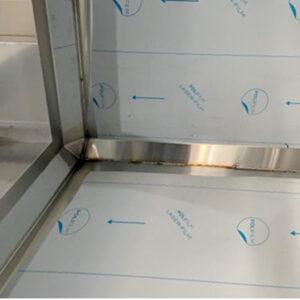

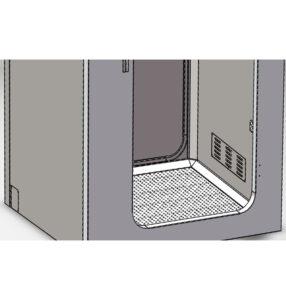

Overall full welding: All the individual parts and components of the water shower cabin, including the walls, corners, and seams, are welded together to form a single, cohesive unit. This construction approach enhances the integrity of the water shower’s containment and ensures airtightness, which is crucial for preventing the leakage of pollutants or contaminants.

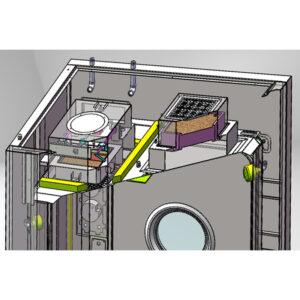

Air outlet port: An opening that allows trapped air to escape from the shower cabin. This ensures even water flow and a comfortable shower experience by preventing airlocks and pressure imbalances.

Water outlet port: A crucial component that allows used water, along with any contaminants or particles it may carry, to be efficiently removed from the shower area. It prevents pooling, and maintaining cleanliness and connects to a drainage system that carries the used water away from the shower area for appropriate treatment or disposal.

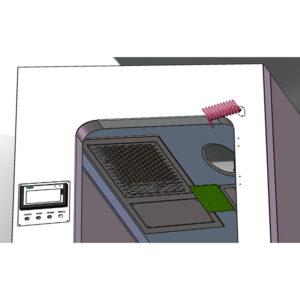

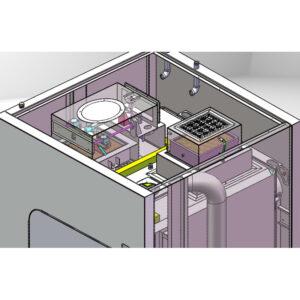

Exhaust HEPA box with scanning and disinfection devices: Vital part of the water shower setup. It uses a HEPA filter to clean the air, while the scanning device checks for contaminants on surfaces. The disinfection device eliminates any biological or chemical pollutants. This integrated system enhances decontamination in settings like labs and pharmaceutical facilities.

PAO Supply and Test Port

Top HEPA box with PAO supply and test port: It sits on top of the shower area and has a HEPA filter inside to clean the air. It also has a PAO for testing. This box ensures that the air inside the shower is clean, and it allows testing to make sure the shower is working properly.

Air return grills are located at the bottom: Allow air to be drawn out from the inside. This air extraction creates a negative pressure environment within the chamber which prevents the potential release of any contaminants or pollutants from the shower chamber into the surrounding environment.

Auxiliary shower heads: In addition to the main shower head which delivers the main stream of water, there are additional shower heads positioned on both sides of the shower cabin. These auxiliary shower heads provide extra water coverage from the sides, ensuring thorough rinsing and coverage of the person or item being cleaned.

Installation and Maintenance

Installing a Cleanroom Water Shower

When installing a cleanroom water shower, it’s essential to consider the layout of the cleanroom and the specific needs of the environment. Proper installation can help ensure the effectiveness of the shower and prevent contamination.

Maintaining a Cleanroom Water Shower

Regular maintenance is critical to ensure the continued effectiveness of a cleanroom water shower. This includes regular cleaning, calibration of sensors, and replacement of filters and other components as needed.

FAQs

Cleanroom water showers can be used in a variety of cleanroom environments, but it’s important to choose the right type of shower for the specific needs of the environment.

Cleanroom water showers should be used as frequently as necessary to maintain the sterility of the environment. This will depend on the specific needs of the environment and the type of contaminants present.

Cleanroom water showers typically use purified water to ensure that no additional contaminants are introduced into the environment.

Cleanroom water showers are generally safe to use, but it’s important to follow proper safety protocols and ensure that the water temperature and pressure are appropriate for personnel and equipment.

Yes, cleanroom water showers can be designed to accommodate both personnel and equipment. Walk-through showers are typically used for larger equipment, while smaller equipment can be washed in manual or automatic showers.

Automatic cleanroom water showers are equipped with sensors that detect when personnel enters the shower. The sensors activate the water jets to remove contaminants from personnel before they enter the cleanroom environment.

Yes, cleanroom water showers can be customized to fit specific cleanroom needs. This includes adjusting the water temperature and pressure, adding additional sensors or controls, and incorporating different types of filtration systems.

Walk-through cleanroom water showers are designed to accommodate personnel and equipment. Personnel and equipment are washed as they move through the shower, with water jets positioned at various heights to ensure thorough cleaning.

Cleanroom water showers are designed to remove a variety of contaminants, including dust, dirt, oils, and other particles that can be introduced into the environment.

Cleanroom water showers can use a significant amount of water, which can be a concern in areas with water scarcity. However, many cleanroom water showers are designed to conserve water and use advanced filtration systems to minimize environmental impact.

By removing contaminants from personnel and equipment before they enter the cleanroom environment, cleanroom water showers help minimize the risk of contamination and maintain the sterility of the environment. This helps ensure the quality and safety of products produced in the cleanroom.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Advanced Features of YOUTH Cleanroom Water Showers

- Cleanroom Air Showers: Key Features and Benefits for Controlled Environments

- YOUTH Cleanroom Water Showers: Ensuring Sterility and Safety in Controlled Environments

- The Ultimate Guide to YOUTH Cleanroom Water Showers: Ensuring Sterility and Safety

- The Impact of Fan Filter Units on Pharmaceutical Product Quality

- Fan Filter Units: A Comprehensive Solution for Cleanroom Air Purification

- Innovative Fan Filter Units for the Next Generation of Cleanrooms

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs