What's the Sterile Liquid Transfer Port SLTP System?

The Sterile Liquid Transfer Port – SLTP system is designed for the transfer of critical fluids during pharmaceutical and biopharmaceutical production. It eliminates the need for physically moving boxes and tote bags, reducing the risks associated with breakage, spillage, and product loss. This system provides a practical, safe, and simple solution for transferring large volumes of liquid between rooms while minimizing the risk of cross-contamination. With proper installation, there is no need for revalidation between product transfer processes.

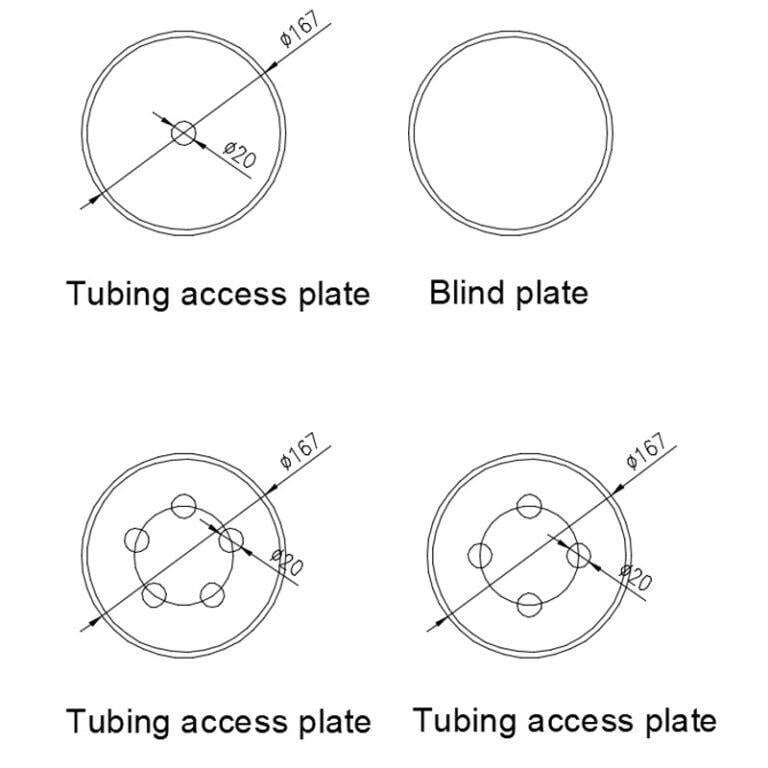

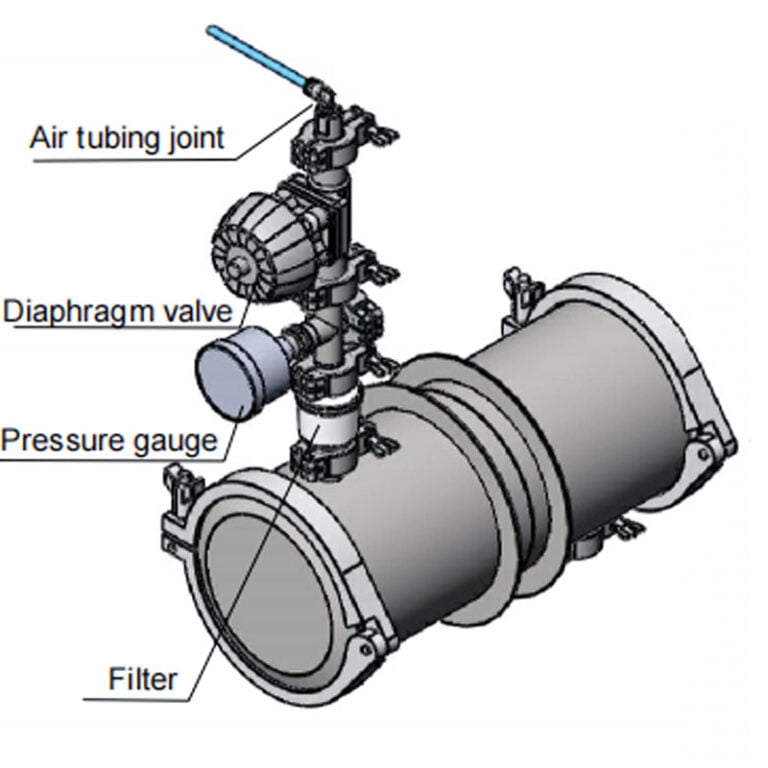

SLTP offers optional purification ports and comes in customizable sizes ranging from 4″ to 8″. It can be tailored to meet specific customer requirements, utilizing standardized components such as blind holes or multiple ports. The system can be equipped with gas pipe connectors, diaphragm valves, pressure gauges, and sterilizing filters, among other accessories, to accommodate various room configurations and fulfill diverse customer needs.

Key Features of Sterile Liquid Transfer Ports

YOUTH’s sterile liquid transfer ports boast a range of features that set them apart. First and foremost is their meticulous design and construction, which ensures optimal performance and durability. The ports incorporate advanced sterility assurance mechanisms, such as double-door systems and aseptic connections, to prevent the ingress of contaminants during transfers. Additionally, YOUTH’s transfer ports are compatible with various containers and equipment, making them versatile and adaptable to different manufacturing and research processes.

Applications of Sterile Liquid Transfer Ports

Sterile liquid transfer ports find application across a spectrum of industries. In pharmaceutical manufacturing, these ports are vital for aseptic filling, sampling, and product transfers between different production areas. Biotechnology research and development laboratories rely on transfer ports for contamination-free cell culture transfers, media additions, and sample handling. Even clinical laboratories benefit from the use of sterile liquid transfer ports, ensuring accuracy and reliability in diagnostic testing.

The steps for using the fluid pass-through system (SLTP)

- Preparation: Ensure that the installation location for the SLTP system is ready, and all components and accessories of the system are prepared.

- Size verification: Select the appropriate SLTP size based on requirements and ensure it accommodates the desired fluid capacity and pipe connections.

- Installation preparation: Clean and sanitize the SLTP components as necessary to meet hygiene standards. Inspect and confirm the integrity and sealing of all connection parts.

- Installation of the SLTP system: Install the components and accessories of the SLTP system at the prepared location following the installation guide and drawings. Ensure connections are securely tightened and properly installed to ensure system stability and safety.

- Connect the pipelines: Connect the pipelines for the fluid to be transferred to the inlet and outlet of the SLTP system. Use appropriate fittings and seals to ensure a secure and reliable connection between the pipelines and the SLTP system.

- Fluid transfer operation: Start and control fluid transfer using the appropriate control devices according to the operation manual and process requirements. Ensure the system operates according to predetermined parameters and procedures.

- Monitoring and adjustment: Regularly monitor the operating status and fluid transfer process of the SLTP system. Make adjustments and optimizations as needed to ensure efficient and safe fluid transfer.

- Maintenance and cleaning: Perform regular maintenance and cleaning of the SLTP system, including cleaning and sanitizing the components and accessories of the system. Ensure system reliability and compliance with hygiene standards.

Types of Sterile Liquid Transfer Ports

Sterile liquid transfer ports come in different types, each catering to specific requirements. Passive transfer ports provide a sealed barrier, allowing transfers without breaking containment. Active transfer ports, on the other hand, utilize mechanisms such as peristaltic pumps or venting systems for more controlled transfers. Both single-use and multiple-use transfer ports are available, offering flexibility in terms of usage and cost-effectiveness. Single-use transfer ports provide the advantage of disposability, eliminating the need for cleaning and validation, while multiple-use transfer ports are designed for repeated use with proper maintenance and sterilization procedures.

How to Choose the Right Sterile Liquid Transfer Port

Selecting the appropriate sterile liquid transfer port is crucial to ensure seamless integration into your processes. Consider factors such as compatibility with your equipment and containers, ensuring a secure and leak-free connection. Regulatory compliance is also essential, as transfer ports must meet industry standards and guidelines to guarantee product quality and safety. Evaluate the ease of use and maintenance requirements, as user-friendly transfer ports minimize the risk of human error and downtime.

Best Practices for Sterile Liquid Transfer Port Usage

To maximize the benefits of sterile liquid transfer ports, it is vital to implement best practices. Proper handling and cleaning procedures are imperative to maintain sterility. Training and education for personnel involved in transfers are essential to ensure correct usage and adherence to protocols. Regular maintenance and inspection of transfer ports help identify any potential issues and ensure their optimal performance.

Advancements and Innovations in Sterile Liquid Transfer Ports

The field of sterile liquid transfer ports continues to evolve, with advancements and innovations driving improved safety and efficiency. Automation and integration play a significant role, streamlining processes and reducing the risk of human error. Enhanced sterility assurance mechanisms, such as advanced sealing technologies and air filtration systems, provide additional layers of protection. Furthermore, user experience has been a focal point, with ergonomic designs and intuitive interfaces simplifying operations and reducing training time.

YOUTH's Sterile Liquid Transfer Port Solutions

YOUTH is a leading provider of complete cleanroom solutions, including a comprehensive range of sterile liquid transfer ports. Our transfer ports are designed with utmost precision and adherence to industry standards, ensuring the highest level of sterility assurance. With features like aseptic connections, and compatibility with various containers and equipment, YOUTH’s transfer ports offer unrivaled performance and versatility.

Customer success stories and testimonials are a testament to the reliability and efficiency of YOUTH’s sterile liquid transfer ports. By partnering with YOUTH, pharmaceutical and biotechnology companies have experienced improved productivity, reduced contamination risks, and enhanced product quality.

FAQs

A sterile liquid transfer port is a specialized device designed to facilitate the contamination-free transfer of liquids in cleanroom environments.

Sterile liquid transfer ports prevent contamination during liquid transfers, ensuring the integrity of products and protecting personnel from potential hazards.

Yes, YOUTH’s sterile liquid transfer ports are designed to be compatible with a wide range of containers and equipment, offering versatility in various manufacturing and research processes.

There are different types of sterile fluid transfer ports, including passive transfer ports for transferring within rooms of the same cleanliness level, and active transfer ports for transferring between rooms of different cleanliness levels.

Factors to consider when choosing a transfer port include compatibility with equipment, regulatory compliance, and ease of use and maintenance. Consulting with YOUTH’s experts can help identify the most suitable option for your specific needs.

Best practices include following proper handling and cleaning procedures, providing comprehensive training to personnel, and conducting regular maintenance and inspection of the transfer ports.

Yes, YOUTH offers customization options to ensure that transfer ports align with unique process needs and industry-specific standards.

By providing a contamination-free transfer environment, sterile liquid transfer ports help meet regulatory requirements for product quality and safety in the pharmaceutical and biotechnology industries.

Yes, YOUTH’s transfer ports are designed with ease of cleaning and maintenance in mind, simplifying the process and minimizing downtime.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Ensuring Sterility and Efficiency: The Power of YOUTH’s Sterile Liquid Transfer Ports

- Ensuring Sterility and Efficiency: The Power of YOUTH’s Sterile Liquid Transfer Ports

- Maintaining Sterility in Cleanrooms: The Role of YOUTH’s Sterile Liquid Transfer Ports and Pass Boxes

- Enhance Safety and Quality with Open Restricted Access Barrier System (ORABS)

- C-RABS & O-RABS: Why & How?

- Maintaining Cleanroom Integrity: The Essential Features of YOUTH’s Pass Boxes and Sterile Liquid Transfer Ports

- Discover the Benefits of Open Restricted Access Barrier System (ORABS) in Manufacturing

- Why Choose Open Restricted Access Barrier System (ORABS) for Your Pharmaceutical Production?