EQUIPMENT - Quick Guide

What are equipments for the Clean Room?

Cleanroom equipment refers to specialized equipment designed for use within cleanroom environments, adhering to specific standards and protocols. This category encompasses various essential tools such as Sampling Booths, VHP (Vaporized Hydrogen Peroxide) Pass Boxes, LAF (Laminar Air Flow) Trolleys, Bag In Bag Out systems, Static Pass-Boxes, Dynamic Pass-Boxes, LAF units, Air Showers, Mist Showers, Bio-Safety Cabinets, and more. These equipment pieces are tailored to uphold stringent cleanliness levels in industries like biotechnology, pharmaceuticals, microelectronics, laboratories, semiconductor manufacturing, and healthcare settings.

Cleanroom equipment is meticulously crafted to adhere to precise cleanliness standards and is usually constructed from materials that facilitate easy cleaning while minimizing particle shedding. Additionally, these devices often feature design elements like smooth surfaces and rounded corners to prevent the accumulation of contaminants, ensuring a controlled and sterile working environment.

Laminar Airflow – LAF Unit

LAMINAR AIRFLOW – LAF UNIT: The acronym “LAF” stands for “Laminar Airflow” or “Laminar Flow.” A “Laminar Flow Unit” – LAF Unit (also called HEPA Fan Filter Unit) refers to equipment designed to create a controlled and clean environment through unidirectional airflow. Laminar airflow is a specialized type of airflow where air moves in a uniform and parallel manner, without significant turbulence or mixing.

The air in YOUTH LAF units flows in a specific direction (either vertical from top to bottom or horizontal from back to front) to prevent cross-contamination and ensure that the work area remains clean.

The heart of the LAF Unit lies in its high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters, which meticulously trap particles as small as 0.3 micrometers in size. This ensures that the air within the clean zone remains virtually free from contaminants, crucial for industries such as pharmaceuticals, biotechnology, and electronics manufacturing.

Pass - Box

Pass-Box: Explore our Pass-Box selection, a vital component of cleanroom equipment designed to facilitate material transfer while maintaining the integrity of your controlled environment. Our range includes Stainless Steel Dynamic Pass Boxes, Static Pass Boxes, VHP (Vaporized Hydrogen Peroxide) H2O2 Pass Boxes, Sterile Liquid Transfer Ports (SLTPs), and Biosafety Pass Boxes for Cleanrooms. These meticulously engineered solutions are tailored to various cleanroom applications, ensuring the safe and contamination-free transfer of materials. Whether you require dynamic, static, or specialized pass boxes like VHP or biosafety options, we offer cutting-edge solutions to meet your cleanroom’s unique needs. Elevate your contamination control protocols with YOUTH’s advanced Pass-Box technology.

Decontamination Shower

Decontamination Shower: Enhance the cleanliness and safety of your cleanroom with our Decontamination Shower solutions. From decontamination Air Showers to Mist Showers and Water Showers, our innovative range ensures optimal decontamination of personnel and equipment. These showers play a pivotal role in maintaining stringent cleanliness standards. By effectively removing contaminants and particles, they protect your cleanroom environment from potential contamination. Explore our Decontamination Showers to secure a clean and controlled workspace, safeguarding your valuable processes and products.

Biosafety Purification Equipment

Biosafety Purification Equipment: Elevate your cleanroom’s biosafety with our cutting-edge Biosafety Purification Equipment. Our comprehensive range includes Bag In Bag Out (BIBO) systems, VHP & HPV Sterilizers, Biological Safety Cabinets, Bio-Safety Air-Tight Doors, Biosafety Dunk Tanks, Chemical Showers, Sterility Test Isolators, and Bio-Safety Pass-Boxes. Designed to meet the highest biosafety standards, our equipment ensures the protection of personnel and processes from biological contaminants. Trust in YOUTH Biosafety Purification solutions to create a secure and controlled cleanroom environment, vital for industries reliant on uncontaminated products and processes.

Negative/Positive Downflow Booth

Negative/Positive Downflow Booths are critical for industries like pharmaceuticals and chemicals. They effectively manage dust, microorganisms, and hazardous substances. Negative Pressure Booths prevent contaminants from escaping, while Positive Pressure Booths keep external pollutants out. These booths are adaptable and maintain clean working environments for safety and product quality. They include Dispensing Booths, Sampling Booths, Weighing Booths, and Modular Cleanrooms.

Youth-Tech's Feature

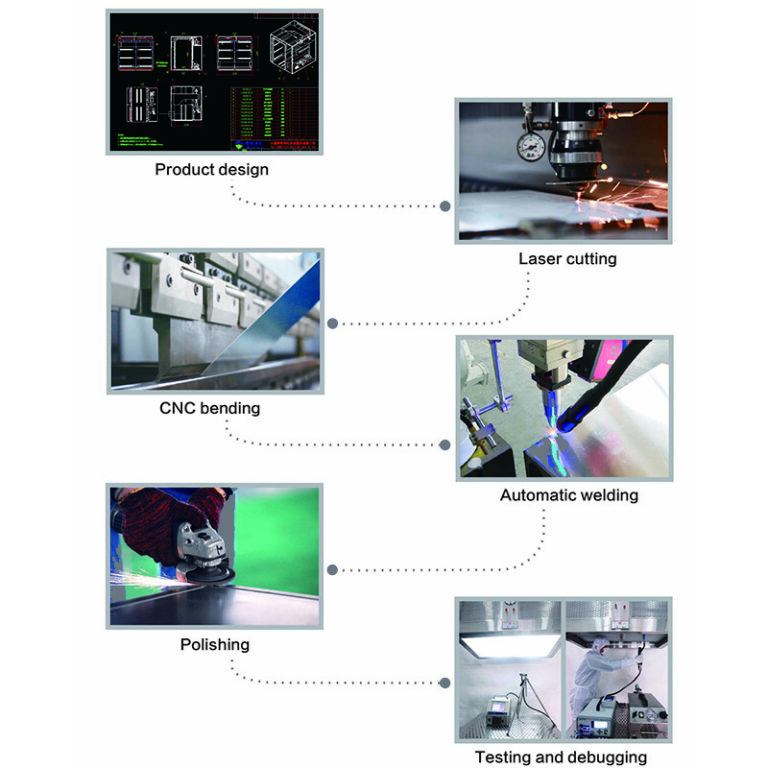

Our company has advanced production management capabilities, including cash laser cutting machines, CNC punching machines, CNC shearing machines, CNC bending machines, and robot welding hands. We also have an imported filter production line (equipment used for filters).

Our team of engineers has over 10 years of experience and actively accumulates industry development technologies to expand product applications. They participate in custom projects from the initial stages and provide complete equipment timelines from design to mass production. We have dedicated project teams to ensure equipment is delivered on time and meets customer requirements.

We strictly control the quality of our equipment and never cut corners. We use high-quality SS304 stainless steel with a thickness of 1.2mm or more, which is consistent in both appearance and internal components. We optimize and design equipment structures reasonably and use international first-class brands for key components. Our working area has an integrated arc design to avoid dead corners and the control modes are diverse.

Our service team is dedicated and can provide on-site training, installation guidance, and testing assistance according to the requirements of both domestic and foreign customers. If we cannot arrive on site promptly, we provide online technical guidance within 24 hours. We use non-recyclable packaging for transportation to ensure convenient, safe, moisture-proof, rust-proof, and shock-resistant delivery of goods. We offer long-term quality assurance and worry-free after-sales service.