What are Chemical Showers?

Cleanroom chemical showers are specialized decontamination systems designed for use in cleanroom environments. These showers provide a dedicated space for personnel to thoroughly cleanse themselves before entering or exiting the cleanroom area. They play a crucial role in maintaining the cleanliness and integrity of the controlled environment.

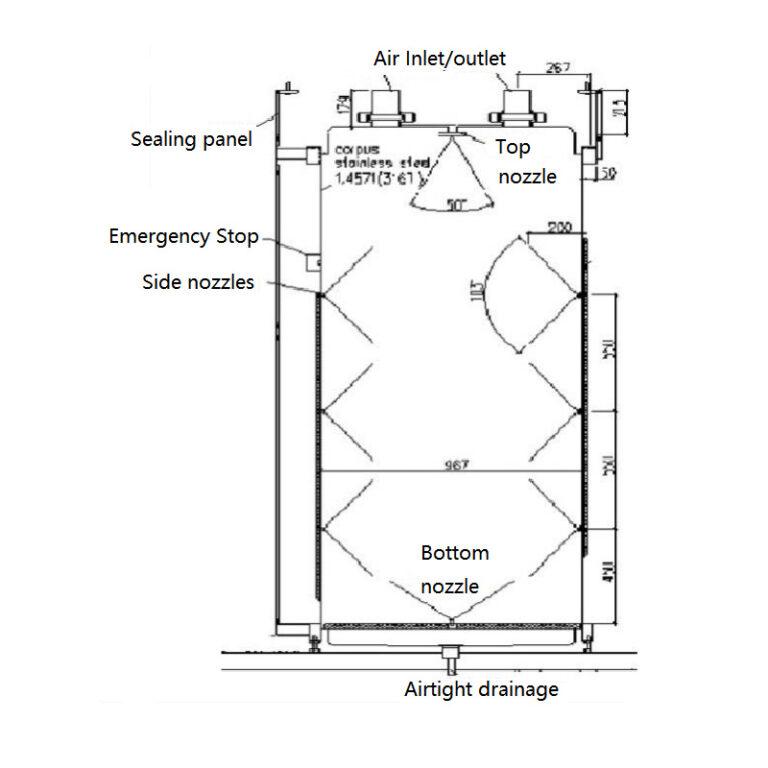

Cleanroom chemical showers are specifically engineered to remove contaminants, such as particles, microbes, and chemicals, from individuals who work in cleanroom environments. They are strategically designed with multiple showerheads and efficient drainage systems to ensure thorough decontamination.

These showers are often equipped with advanced features and technology to enhance their functionality and user experience. Touchless operation, temperature control, and automated disinfection systems are some of the innovative features that may be incorporated into cleanroom chemical showers. These features not only improve the effectiveness of the decontamination process but also contribute to the overall efficiency and convenience of the showers.

Cleanroom chemical showers are essential in preventing the introduction of contaminants into the cleanroom, as even the smallest impurities can have detrimental effects on sensitive processes and products within the controlled environment. By utilizing cleanroom chemical showers, companies can prioritize personnel safety, minimize the risk of cross-contamination, and ensure compliance with industry-specific regulations and standards.

How does chemical showers works?

Chemical showers in cleanroom environments work by utilizing a combination of water and chemical agents to effectively decontaminate individuals before they enter or exit the controlled environment. The process typically involves the following steps:

- Activation: The chemical shower system is activated either manually or through an automated process. This may involve pressing a button, stepping on a floor sensor, or using a touchless control system, depending on the specific design of the shower.

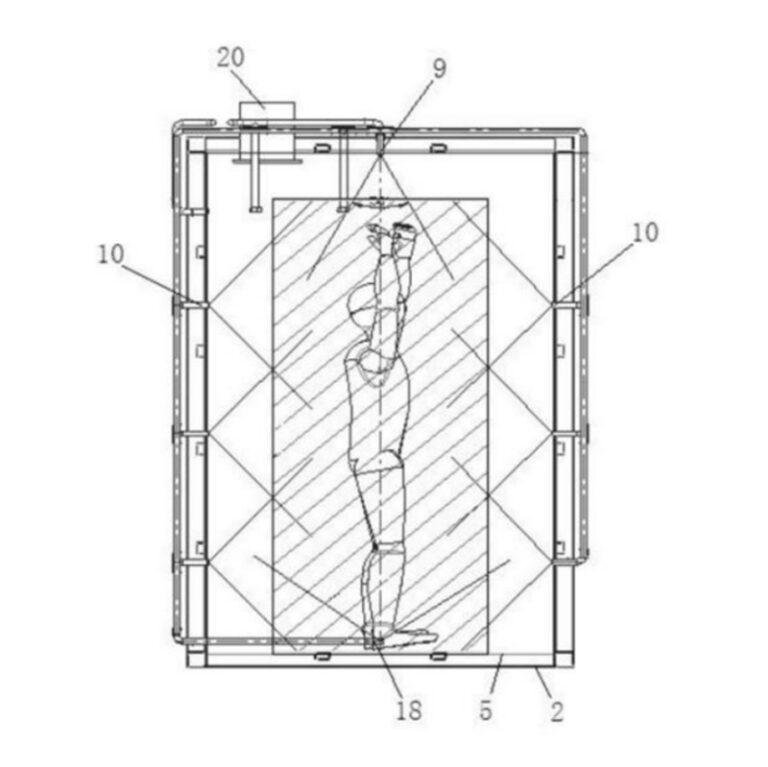

- Water Flow: Upon activation, water begins to flow from strategically positioned showerheads located within the shower enclosure. The water flow is designed to cover the entire body of the person standing in the shower area, ensuring comprehensive decontamination.

- Chemical Agent Dispersion: Along with water, a chemical agent or disinfectant is mixed into the shower water supply. The chemical agent may vary depending on the specific requirements of the cleanroom environment and the contaminants to be removed. The chemical agent aids in the removal of particles, microbes, and other contaminants from the person’s body.

- Contaminant Removal: The combined action of the water and chemical agent helps to dislodge and rinse away contaminants present on the individual’s body. The showerheads are strategically positioned to ensure thorough coverage, effectively removing contaminants from head to toe.

- Drainage: The water and contaminants are directed into a drainage system that is designed to efficiently remove the contaminated water from the shower area. The drainage system may include filters or other mechanisms to prevent the reintroduction of contaminants into the cleanroom environment.

- Drying or Air Shower Option (optional): Depending on the design of the chemical shower system, there may be an option for air showers or drying mechanisms. These features utilize filtered and pressurized air to remove excess moisture from the individual’s body, further enhancing the cleanliness and readiness for cleanroom entry.

It is important to note that the specific operation and features of chemical showers can vary based on the manufacturer and the requirements of the cleanroom facility. YOUTH, a leading provider of cleanroom solutions, offers advanced chemical shower systems designed to optimize decontamination processes and ensure the highest levels of cleanliness and safety within cleanroom environments.

What’s the Benefits of YOUTH’s Cleanroom Chemical Showers?

YOUTH’s cleanroom chemical showers offer numerous benefits that contribute to the overall cleanliness, safety, and efficiency of cleanroom environments. Here are some key benefits of YOUTH’s cleanroom chemical showers:

- Enhanced Personnel Safety: YOUTH prioritizes the safety of personnel with their cleanroom chemical showers. These showers provide a dedicated space for decontamination, minimizing the risk of cross-contamination and protecting individuals from harmful substances. Features like adjustable water pressure and temperature control ensure a comfortable and safe decontamination experience for every user.

- Contamination Control: YOUTH’s cleanroom chemical showers excel in controlling contamination. Strategically placed showerheads and efficient drainage systems effectively remove contaminants from individuals before they enter or exit the cleanroom. This significantly reduces the chance of pollutants compromising the cleanroom’s sterile conditions, maintaining a high level of cleanliness and product integrity.

- Regulatory Compliance: YOUTH understands the importance of adhering to regulatory standards in different industries. Their cleanroom chemical showers are designed to meet the strict guidelines set forth by regulatory bodies. By choosing YOUTH’s solutions, you can ensure compliance with industry-specific requirements, supporting the integrity of your operations and avoiding potential penalties or setbacks.

- Efficient Decontamination Process: YOUTH’s cleanroom chemical showers optimize the decontamination process, making it quick and efficient. The innovative design and functionality of these showers enable thorough cleansing, ensuring that individuals are properly decontaminated before entering or exiting the cleanroom. This efficiency not only saves time but also increases productivity within your facility.

- Ease of Installation and Maintenance: YOUTH prioritizes user convenience with their cleanroom chemical showers. These showers are designed for easy installation, minimizing downtime during the setup process. Additionally, they are engineered for straightforward maintenance, reducing the overall operational burden. YOUTH’s dedication to user-friendly solutions ensures that your cleanroom remains operational with minimal disruptions.

- Customization Options: YOUTH offers customization options to meet the specific needs of different industries and facilities. They understand that cleanroom requirements can vary, and their team of experts works closely with clients to design customized cleanroom chemical showers that optimize functionality and efficiency. This tailored approach ensures that the showers seamlessly integrate into your cleanroom environment.

By choosing YOUTH’s cleanroom chemical showers, you can benefit from enhanced personnel safety, effective contamination control, regulatory compliance, efficient decontamination processes, ease of installation and maintenance, and the flexibility of customization. YOUTH’s commitment to quality and customer satisfaction makes them a trusted partner for cleanroom solutions.

How about YOUTH’s Comprehensive Cleanroom Solutions?

YOUTH is a leading provider of comprehensive cleanroom solutions, offering a wide range of products and services designed to meet the diverse needs of cleanroom environments. In addition to cleanroom chemical showers, YOUTH provides the following comprehensive solutions:

- Cleanroom Design and Construction: YOUTH offers expertise in cleanroom design and construction, ensuring that your cleanroom facility is optimized for functionality, efficiency, and compliance. Their team of professionals works closely with clients to understand their specific requirements and design cleanrooms that meet industry standards and regulatory guidelines.

- Cleanroom Equipment and Furnishings: YOUTH supplies a wide range of state-of-the-art cleanroom equipment and furnishings to support your cleanroom operations. This includes cleanroom workstations, storage solutions, HVAC systems, air filtration units, particle counters, and more. YOUTH ensures that their equipment is of the highest quality and meets the stringent demands of cleanroom environments.

- Cleanroom Certification Services: YOUTH offers reliable cleanroom certification services to validate the cleanliness and functionality of your cleanroom facility. Their certification experts perform thorough inspections, particle count measurements, air flow analysis, and other tests to ensure compliance with industry standards. Certification from YOUTH provides confidence in the integrity of your cleanroom.

- Cleanroom Training and Consultation: YOUTH provides comprehensive training programs and consultation services to help you understand and implement best practices for cleanroom operations. Their experienced professionals offer guidance on contamination control, proper gowning procedures, cleanroom behavior, and other critical aspects of maintaining a clean and controlled environment.

- Cleanroom Maintenance and Support: YOUTH understands the importance of ongoing maintenance to ensure the optimal performance of your cleanroom. They offer maintenance services and support to keep your cleanroom equipment and systems in top condition. This includes regular inspections, filter replacements, calibration services, and troubleshooting support to minimize downtime and maximize productivity.

YOUTH’s comprehensive cleanroom solutions cover the entire lifecycle of cleanroom development, from design and construction to equipment supply, certification, training, and maintenance. Their commitment to quality, expertise, and customer satisfaction ensures that you receive reliable and efficient solutions tailored to your specific cleanroom requirements.

By choosing YOUTH as your cleanroom partner, you gain access to a wide range of products, services, and expertise to create and maintain a clean and controlled environment that meets the highest standards of cleanliness, safety, and regulatory compliance.

How to Choosing the Right Cleanroom Chemical Shower for Your Facility?

Choosing the right cleanroom chemical shower for your facility is a critical decision that requires careful consideration of several factors. Here are some key steps to guide you in selecting the appropriate cleanroom chemical shower:

- Assess Your Facility’s Needs: Begin by assessing your facility’s specific requirements. Consider factors such as the size of the cleanroom, the number of personnel using the shower, the types of contaminants present, and any industry-specific regulations or guidelines that must be followed. This evaluation will help you determine the features and specifications needed in a cleanroom chemical shower.

- Define the Decontamination Process: Clearly define the decontamination process you want to achieve. Consider aspects such as the required water flow rate, temperature control, and chemical agents to be used. Determine if additional features such as touchless operation, automated disinfection systems, or drying mechanisms are necessary for your facility.

- Evaluate Manufacturer Expertise: Research reputable cleanroom solution providers like YOUTH who have expertise in cleanroom chemical showers. Look for manufacturers with a strong track record, extensive experience, and positive customer reviews. Assess their product quality, innovation, and ability to customize solutions to fit your specific needs.

- Consider Compliance and Certification: Ensure that the cleanroom chemical shower meets industry-specific regulations and standards. Look for certifications and compliance with organizations such as ISO, FDA, and cGMP. Compliance with these standards is crucial for maintaining a controlled and sterile cleanroom environment.

- Evaluate Ease of Installation and Maintenance: Consider the ease of installation and maintenance of the cleanroom chemical shower. Look for showers that are designed for easy installation and offer straightforward maintenance procedures. This will help minimize downtime and operational disruptions in your facility.

- Request Product Demonstrations and Samples: Request product demonstrations or samples from potential manufacturers. This will allow you to evaluate the functionality, performance, and user experience of the cleanroom chemical showers firsthand. Testing the showers in your facility’s environment will help you make an informed decision.

- Seek Expert Consultation: If needed, consult with cleanroom specialists or experts who can provide guidance and recommendations based on their industry knowledge and experience. They can offer valuable insights and help you navigate through the selection process, ensuring that you choose the most suitable cleanroom chemical shower for your facility.

- Consider Long-Term Support: Evaluate the manufacturer’s after-sales support, warranty, and customer service. A reliable provider like YOUTH should offer excellent customer support, including technical assistance, maintenance advice, and responsive service to address any concerns or issues that may arise.

By following these steps and considering your facility’s specific needs, compliance requirements, manufacturer expertise, ease of installation and maintenance, and long-term support, you can confidently choose the right cleanroom chemical shower that meets your facility’s decontamination needs and contributes to a safe and controlled cleanroom environment.

How YOUTH Ensures Customer Satisfaction?

YOUTH is committed to ensuring customer satisfaction by providing high-quality cleanroom solutions and delivering exceptional service. Here are some ways in which YOUTH ensures customer satisfaction:

- Quality Products: YOUTH focuses on delivering products of the highest quality. Their cleanroom chemical showers and other cleanroom solutions are built using premium materials, innovative technologies, and rigorous manufacturing processes. By maintaining stringent quality control standards, YOUTH ensures that their products meet or exceed customer expectations.

- Customization Options: YOUTH understands that each cleanroom facility has unique requirements. They offer customization options to tailor their cleanroom solutions to specific customer needs. Whether it’s modifying the design of a cleanroom chemical shower or providing personalized equipment configurations, YOUTH works closely with customers to deliver solutions that best fit their requirements.

- Expert Guidance: YOUTH’s team of experts provides knowledgeable guidance and support to customers throughout the entire process, from initial consultation to post-sales assistance. Their cleanroom specialists offer insights, recommendations, and technical expertise to help customers make informed decisions and achieve optimal cleanroom performance.

- Timely Delivery and Installation: YOUTH values promptness and efficiency in delivering their cleanroom solutions. They strive to ensure timely delivery and installation, minimizing any potential disruptions to customer operations. By adhering to agreed-upon schedules and providing efficient installation services, YOUTH demonstrates their commitment to customer satisfaction.

- Comprehensive Training: YOUTH offers comprehensive training programs to educate customers on proper cleanroom practices, equipment usage, and maintenance. They equip customers with the knowledge and skills necessary to effectively operate and maintain their cleanroom solutions, ensuring long-term performance and maximizing the return on investment.

- Responsive Customer Support: YOUTH maintains a responsive customer support system to address any inquiries, concerns, or technical issues that customers may have. Their support team is readily available to provide assistance, troubleshoot problems, and offer solutions promptly. This commitment to responsive customer support ensures that customers feel supported and their needs are met.

- Continuous Improvement: YOUTH is dedicated to continuous improvement in their products, services, and processes. They actively seek customer feedback and incorporate it into their operations, enabling them to enhance their offerings based on real-world experiences and evolving customer needs. This customer-centric approach ensures that YOUTH consistently delivers solutions that align with customer expectations.

By prioritizing quality, offering customization options, providing expert guidance, ensuring timely delivery and installation, offering comprehensive training, maintaining responsive customer support, and embracing continuous improvement, YOUTH strives to exceed customer expectations and ensure their satisfaction at every stage of the customer journey.

Basic information:

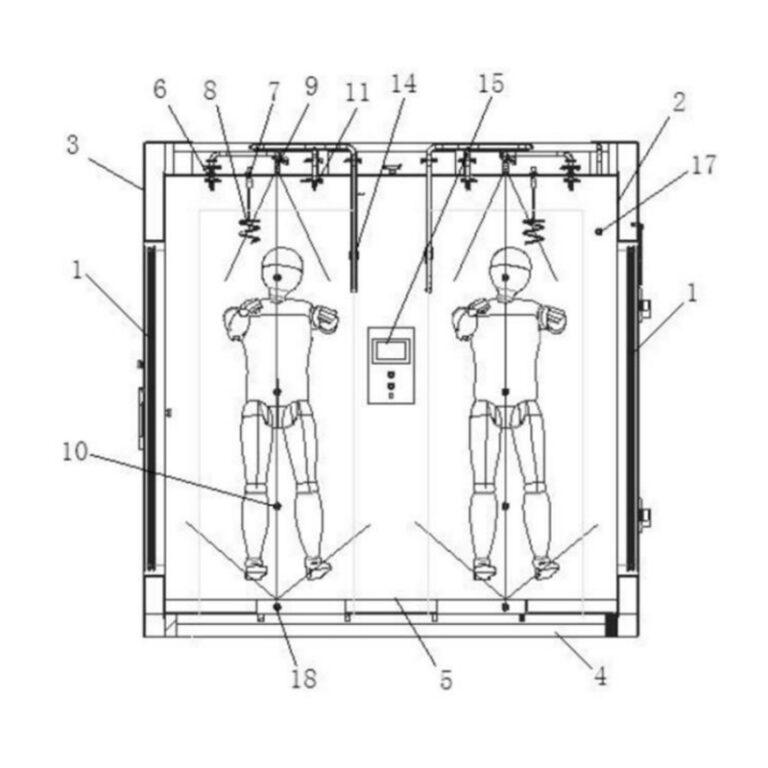

Supports two persons wearing positive-pressure protective suits to use simultaneously.

air Tightness: The natural pressure decay within 20 minutes after the air pressure inside the box reaches 500 Pa is less than 250 Pa.

Pressure-bearing Capacity: The box structure should withstand a pressure of 1000 Pa.

Equipment Material: The shell is made of 304 stainless steel, and the shower room is made of 316 stainless steel (pipes, atomizing nozzles, etc.).

Functional Requirements: Automatic liquid dispensing, automatic medication showering, automatic cleaning, and manual emergency spray.

Spray Pressure: 0.5 ~ 0.7 Mpa;

Spray Flow: 30 ~ 50L/min

Spraying Principle: High-pressure atomization for more uniform and comprehensive coverage.

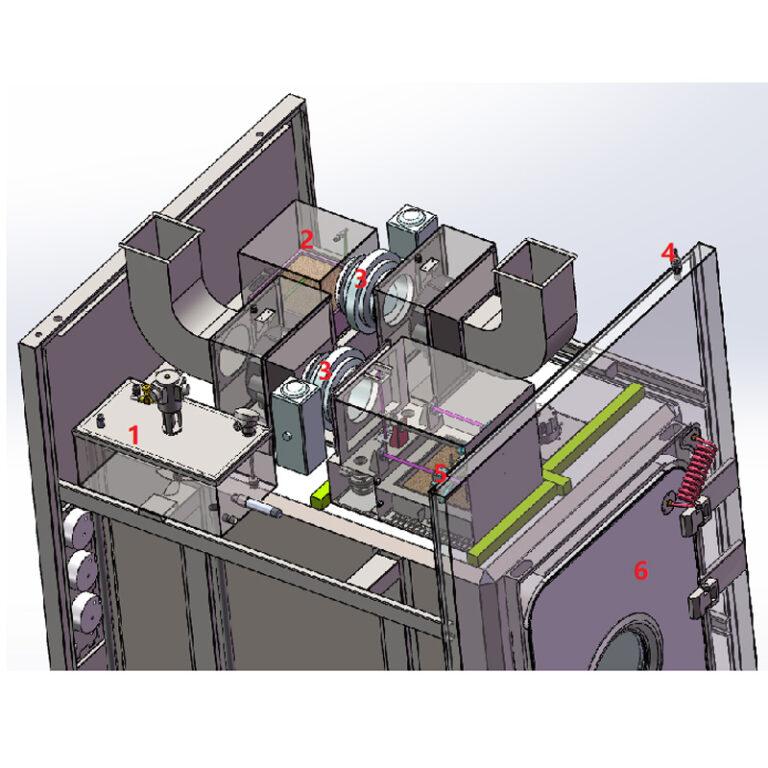

Liquid Dispensing System: Automatically dispense disinfectant with a mixing device and level and concentration monitoring equipment.

Medicine Tank: Made of polyethylene (PE) with strong corrosion resistance.

Chemical Agents: Suitable for hydrogen peroxide disinfectants, chlorine-containing disinfectants, acidic oxidizing potential water, and commonly used disinfectants on the market.

Bio-Safety Airtight Door: Inflatable airtight door with interlocking device for higher safety.

Control System: Intelligent automation control with abnormal level and pH value alarms and remote monitoring function.

Pneumatic Floor Drain: Effectively ensures the airtightness of the chemical shower system.

Life Support System: Standard configuration.

Personnel disinfection process:

Pre-cleaning—spraying disinfectant—reaction exposure—water flushing—floor drain opening—inflating and drying (drying);

Box disinfection process (personnel enter the chemical shower system in batches, and the box is disinfected at intervals):

Spraying disinfectant;——reaction exposure;——floor drain opening;

- High-Pressure Shower

- Double Airtight Door Design(Intelligent Interlocking)

- Efficient Top Air Supply (with AirtightValve)

- High-efficiency Blowing at the Top(with Airtight Valve)

- Independent Water Supply

- Independent Air Supply

- Negative Pressure Environment

- Life Support System

- Emergency Shower System (Spray. Spray)

- Automatic Dispensing

- Automatic Cleaning

- Airtight Floor Drain

- Water tank

- Air inlet HEPA

- Airtight valve

- Oxygen supply interface

- Air outlet HEPA

- Biosafety airtight doors

Types of Chemical Showers

There are several types of chemical showers available, each with its advantages and disadvantages. Some of the most common types include:

Wet Chemical Showers: Wet chemical showers use a combination of water and a chemical solution to decontaminate personnel and equipment. These showers typically feature spray nozzles that distribute the solution over the individual or equipment being decontaminated.

Dry Chemical Showers: Dry chemical showers use a combination of compressed air and a dry chemical powder to decontaminate personnel and equipment. These showers typically feature an enclosed booth that fills with dry chemical powder, which adheres to surfaces and neutralizes contaminants.

Hybrid Chemical Showers: Hybrid chemical showers combine the benefits of wet and dry chemical showers, using a combination of water and dry chemical powder to decontaminate personnel and equipment.

Advantages of Using Chemical Showers

Chemical showers offer several advantages over other decontamination methods, including:

Efficiency: Chemical showers are designed to provide a quick and efficient method for decontamination, reducing the time required for personnel and equipment to enter the cleanroom.

Versatility: Chemical showers can be used to decontaminate both personnel and equipment, making them an ideal solution for cleanrooms with high levels of foot traffic.

Effectiveness: Chemical showers are highly effective at neutralizing and removing contaminants from surfaces, reducing the risk of contamination within the cleanroom.

Related Contents:

- Unlocking the Power of Hydrogen Water Generators

- Advanced Features of YOUTH Cleanroom Water Showers

- Vaporized Hydrogen Peroxide: Revolutionizing Pharmaceutical Decontamination

- YOUTH Cleanroom Water Showers: Ensuring Sterility and Safety in Controlled Environments

- The Evolution of BIBO Systems in Chemical Manufacturing

- The Ultimate Guide to YOUTH Cleanroom Water Showers: Ensuring Sterility and Safety

- The Environmental Impact of VHP Sterilization in Cleanrooms

- Cleanroom Air Showers: Key Features and Benefits for Controlled Environments

- Maintaining and Calibrating VHP Generators for Optimal Performance