Introduction

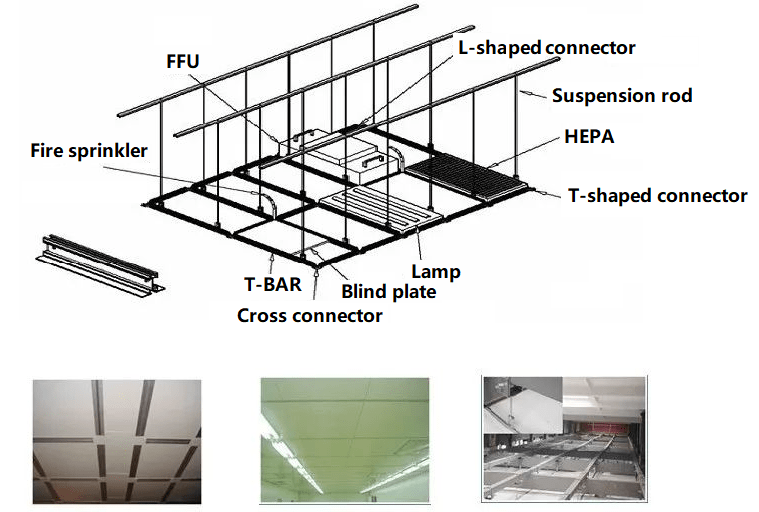

For those who have been inside a clean room, the components on the ceiling are likely familiar: high-efficiency filters, light fixtures, smoke detectors, and sprinklers. In this article, we will specifically discuss the most commonly used high-efficiency filters, known as HEPA filters. We will explore their significance, composition, and the crucial role they play in ensuring the quality of pharmaceutical production in clean rooms.

Why Install HEPA Filters and their Composition

The Good Manufacturing Practice (GMP) regulations stipulate that the production of preparations, raw materials for drugs, packaging materials directly in contact with drugs, and other pharmaceutical processes should all take place within clean room environments. A pharmaceutical clean room is an area where specific environmental controls are implemented to minimize contamination from particles and microorganisms. These contaminants can directly affect the quality of pharmaceutical products and pose serious risks to human life.

Research indicates that contamination by 7-2μm particles, particularly in intravenous medications, can lead to adverse reactions such as pyrogenic reactions, pulmonary artery inflammation, micro-thrombi, or foreign body granulomas, with severe cases even resulting in fatalities. The presence of particles in the bloodstream can harm the body, depending on their quantity, size, and physical properties.

Pharmaceutical clean rooms not only need to control particle contamination but also microbial contamination. Microbial contamination, caused by bacteria and fungi, is even more detrimental to pharmaceutical products and human health. Microorganisms can propagate rapidly and are found everywhere. Most airborne microorganisms attach to dust particles or float in the air as spores. Controlling microbial contamination is critical to prevent adverse effects.

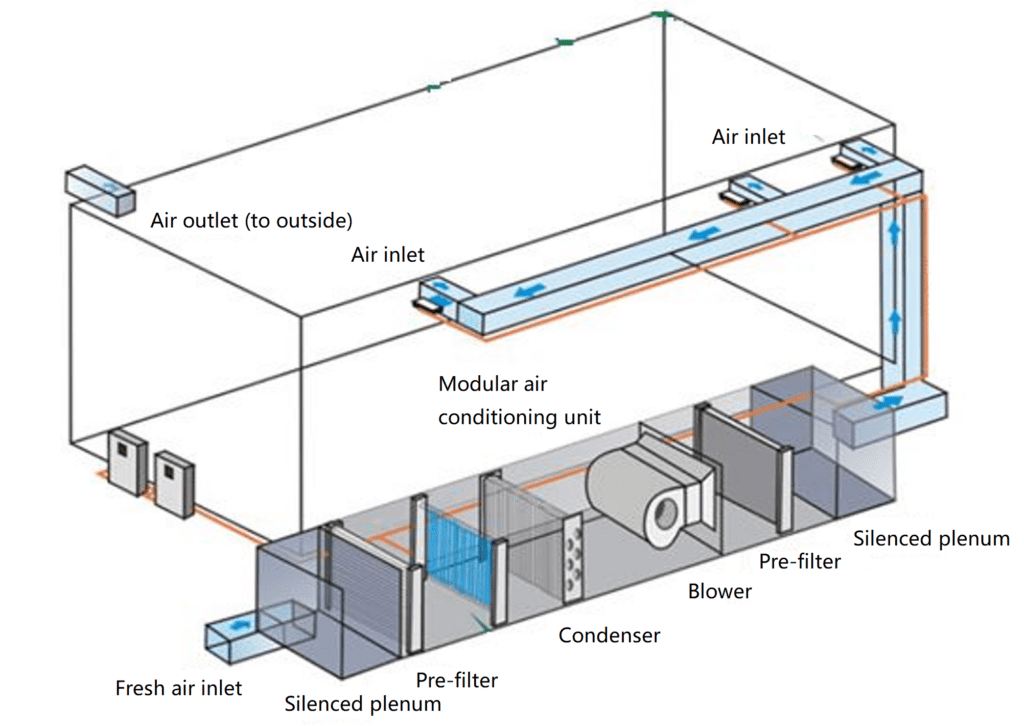

The cleanliness level of pharmaceutical clean rooms, as outlined by the State Drug Administration (SDA) regulations, reflects the requirements for controlling both particles and microorganisms. Therefore, it is essential to filter the air inside clean rooms before they can be put into use. The use of HEPA filters is crucial in achieving the required air purity. HEPA filters meet the High-Efficiency Particulate Air Filter standard, providing an efficiency of 99.998% for particles of 0.1μm and 0.3μm.

These filters are made from ultra-fine glass fiber paper as the filtering medium, with separator plates made from materials such as cardboard, aluminum foil, etc. The filters are sealed with a new type of polyurethane sealant and framed with galvanized plates, stainless steel plates, or aluminum alloy profiles.

01. Bag & Pocket Pre Air Filter

What are Cleanroom Bag&Pocket pre-air filters? Cleanroom Bag&Pocket pre air filter is a type of air filter that removes contaminants and

01. Bag In Bag Out – BIBO

Understanding Bag In Bag Out (BIBO) Systems Bag In Bag Out (BIBO) systems represent the gold standard in contamination control technology

01. CleanRoom Air Shower

What is the cleanroom air shower? https://www.youtube.com/watch?v=aufu9JhpElk A Cleanroom Air Shower is a self-contained chamber that uses high-velocity HEPA-filtered air to

01. Cleanroom Gowning Cabinet

A cleanroom gowning cabinet is a type of cabinet that is specifically designed and used for storing personal protective equipment (PPE)

01. Dynamic Pass Box

Product Features and Applications Dynamic pass box is a purification equipment that provides a locally high cleanliness working environment and has

01. Laminar Air Flow Unit – LAF Unit

What is a LAF? A-Class laminar air flow hood is a controlled airflow system used in healthcare, pharmaceuticals, electronics, and research

Installation of HEPA Filters in Clean Rooms

The proper installation of HEPA filters is critical for the purification of air conditioning systems and clean room construction. Several key points must be considered:

Pre-installation Cleaning

Before installation, the system should be air-blown clean, and the cleanroom should undergo comprehensive cleaning. A vacuum cleaner with ultra-clean filter bags must be used; ordinary vacuum cleaners are not allowed. If the filters will be installed inside the ceiling, the ceiling should be cleaned as well.

Trial Run and Post-Cleaning

After the system runs for 12 hours, the clean room should be cleaned again before the installation of HEPA filters.

During installation, the filters should be unpacked at the installation site. An external inspection should be carried out to check for any damages, and specific performance data should be provided for each unit.

For clean rooms with cleanliness levels equal to or higher than Class 100, a leak test of the installed HEPA filters must be performed on-site, focusing on detecting any self-quality issues such as damages or leaks. For clean rooms with other cleanliness levels, a leak test should also be conducted at a self-determined proportion.

The primary focus of the leak test is to ensure the quality of the air filter frame seal.

Due to the extensive content on leak testing, capabilities, replacement, maintenance, and other information, this will be covered in the subsequent section.

Conclusion

In conclusion, high-efficiency filters (HEPA) play a crucial role in pharmaceutical clean rooms, effectively controlling both particles and microorganisms. Their installation and maintenance are of utmost importance to ensure the production of high-quality pharmaceutical products and safeguarding human health. Complying with GMP regulations and adhering to the standards set by the State Drug Administration are essential steps to achieve optimal results in clean room environments.

FAQs:

1. What are HEPA filters?

HEPA filters, which stand for High-Efficiency Particulate Air Filters, are highly efficient filters used to capture particles and microorganisms from the air, providing clean and contaminant-free air in clean room environments.

2. Why are HEPA filters essential in pharmaceutical production?

HEPA filters are vital in pharmaceutical production as they prevent particle and microbial contamination, ensuring the quality and safety of pharmaceutical products.

3. What is the significance of leak testing HEPA filters?

Leak testing is critical to verify the integrity of HEPA filters and ensure that they are free from damages or leaks that could compromise their filtering efficiency.

4. How often should HEPA filters be replaced?

HEPA filters should be replaced regularly as per the manufacturer’s recommendations to maintain optimal filtration efficiency and ensure cleanroom performance. Usually 1 year in a regular cleanroom environment.

5. Can HEPA filters capture airborne viruses?

Yes, HEPA filters can capture airborne viruses and other microorganisms, making them an effective tool for controlling contamination in clean room environments.

Related Contents:

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Unlocking the Power of Clean Room Purification: Four Vital Conditions

- Can Positive Pressure Clean Operating Rooms Be Used for COVID-19 Patients? Understanding Disinfection

- Mastering Clean Room Technology with Fan Filter Units (FFUs)

- Ranking the Best “Cleanroom” Air Filter Brands of 2023

- What is the Main Difference between HEPA and ULPA?

- Revolutionizing Cleanrooms Equipment: Affordable and Efficient Design and Construction

- HEPA Filter Maintenance: Ensuring Peak Performance

- What are Clean Room Systems?