Comparing Vertical and Horizontal Laminar Air Flow Trolleys

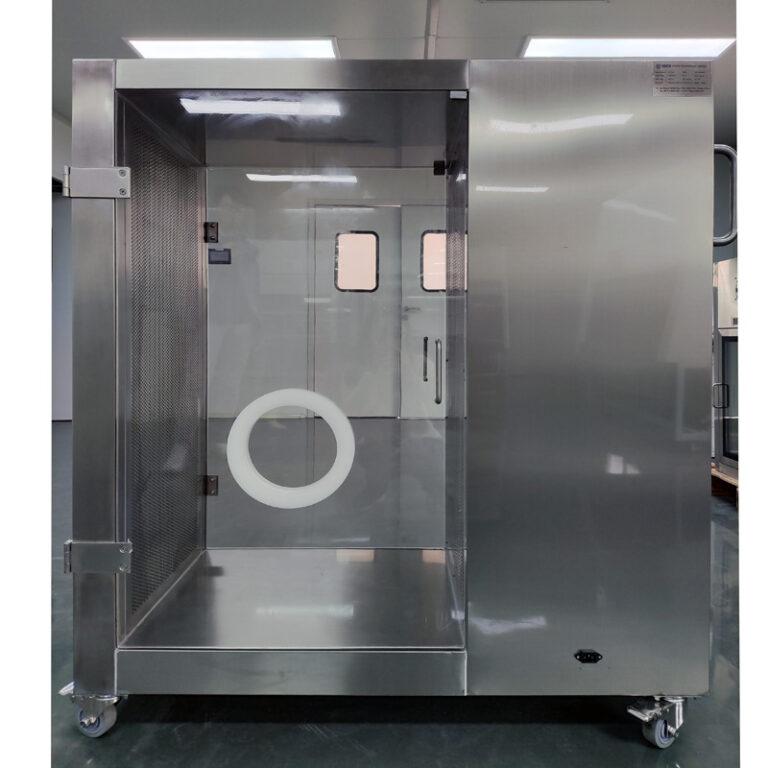

Laminar Air Flow Trolleys are indispensable assets within controlled environments such as cleanrooms, where maintaining sterility and preventing contamination are paramount. Two primary variations exist in the design of these trolleys: Vertical and Horizontal Laminar Air Flow Trolleys.

(Siemens PLC)

(Siemens PLC)

Horizontal Laminar Air Flow Trolley: Flowing Precision

In contrast, the Horizontal Laminar Air Flow Trolley utilizes a horizontal airflow pattern. The air flows parallel to the surface of the trolley, safeguarding materials as they move from one point to another. This design is especially beneficial for larger or bulkier items that may not fit within the confines of a vertical design.

Vertical Laminar Air Flow Trolley: Elevating Sterility

A Vertical Laminar Air Flow Trolley is meticulously engineered to maintain a controlled, sterile environment while transporting materials. This type of trolley employs a vertical airflow pattern, where the air is directed from the top of the trolley downwards. The primary objective of this design is to prevent any contaminants or particles from coming into contact with the transported materials. The vertical laminar airflow creates a downward stream of purified air, effectively shielding the contents from airborne pollutants.

Choosing the Right Type for Your Needs

The choice between Vertical and Horizontal Laminar Air Flow Trolleys depends on the specific requirements of your industry and the nature of the materials you handle. Vertical trolleys prioritize sterility and protection against contaminants, making them ideal for delicate items. Horizontal trolleys offer flexibility and efficient handling for a broader range of materials.

YOUTH’s LAF Trolley Features

Positive and Negative Pressure:

The trolleys can be configured for positive pressure, suitable for non-hazardous aseptic or sterile products/materials, or negative pressure for operator and environmental protection.

Corrosion Resistance:

Constructed with overall SS304 ≥1.2mm, the trolleys guarantee resistance to corrosion, contributing to their long-lasting performance.

Easy-to-Clean Design:

The trolleys feature an overall full welding construction that simplifies cleaning procedures, a critical aspect in maintaining sterile conditions.

Advanced Filtration:

The gel-sealed HEPA/ULPA filters, produced in a controlled temperature and humidity-clean environment, surpass conventional gasket-sealed systems in terms of efficiency.

Durable Build:

Equipped with 5-10 mm tempered glass doors or PVC curtains according to the customer’s needs, these trolleys ensure visibility while sturdy plastic latches secure the contents.

FDA-Approved Seals:

Incorporating food-grade, FDA-approved pressure-tight seals, the trolleys prevent any potential contamination, ensuring the integrity of transported materials.

(Triac control)

(Triac control)

Smooth Mobility:

Polyurethane (PU) wheels with excellent load-bearing capacity ensure seamless movement across the facility, minimizing disruptions.

Monitoring and Safety:

Equipped with PLC or microprocessor controllers, the trolleys feature audio/visual alarms for downflow velocity, ensuring continuous monitoring and operator safety.

Filter Replacement Reminder (Optional):

Dwyer differential pressure gauges and sensors enable the tracking of filter lifespan, aiding maintenance and upkeep.

Uninterrupted Operation:

An onboard UPS battery allows the trolleys to remain powered for 1-2 hours even when disconnected from the main building supply, ensuring uninterrupted use.

Emergency Preparedness:

An emergency stop feature adds an extra layer of safety, allowing immediate halting of operations when necessary.

YOUTH’s LAF Trolleys are engineered to meet the stringent requirements of sterile material transfer, offering reliable performance, contamination control, and operator safety.

FAQs

Cleanroom Laminar Flow Horizontal Trolleys should be cleaned regularly using an approved disinfectant. The cleaning frequency depends on factors like usage, transported materials, and cleanliness requirements.

Regular inspection and maintenance are crucial. This includes checking components like HEPA filter, fan, motor, and power source. Qualified technicians should handle troubleshooting and repairs.

When selecting a Cleanroom Laminar Flow Vertical Trolley, it’s essential to take into account factors like material weight, size, industry requirements, and the availability of customization options. Additionally, avoid common mistakes such as choosing trolleys that are too small or large, neglecting maintenance needs, and overlooking factors like materials and the intended usage environment.

Yes, customization options include size, weight capacity, and materials used, ensuring they meet specific requirements.

While designed for cleanrooms, they can be used in other contamination-sensitive settings like hospitals or labs.

Yes, customization may include adjustable shelves or lockable wheels to accommodate different materials.

There are stationary/mobile models with various features, such as multiple shelves, adjustable heights, or lockable doors.

Related Contents:

- Navigating Sterility: A Deep Dive into YOUTH’s Vertical and Horizontal Laminar Air Flow Trolleys

- Mastering Cleanroom Mobility: YOUTH’s Vertical and Horizontal Laminar Air Flow Trolleys

- Mastering Cleanroom Mobility with YOUTH’s Mobile Laminar Air Flow Trolleys

- HORIZONTAL VS. VERTICAL LAMINAR FLOW Units: WHAT’S THE DIFFERENCE?

- Unlocking the Power of Clean Room Purification: Four Vital Conditions

- The Distinction Between Weighing Hoods and Laminar Flow Hoods: Adhering to National Clean Hood Standards

- Bag-In/Bag-Out (BIBO) Systems: Operation and Maintenance Guide

- Mastering Cleanroom Environments with YOUTH’s Laminar Air Flow (LAF) Units

- Selecting the Right Fan Filter Unit for Your Cleanroom Needs